- Willkommen bei der Shaanxi Automobile Group

- Webseite:www.shacman3000.com

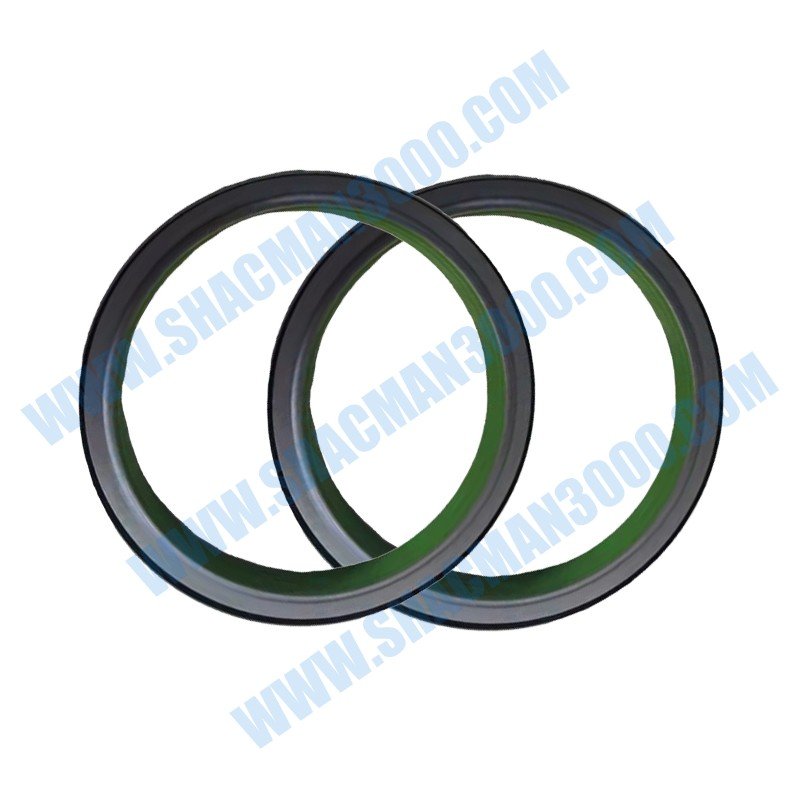

Front Crankshaft Oil Seal

Переднее маслосъемное кольцо коленвала

Retén de Aceite del Cigüeñal Delantero

The Shacman Front Crankshaft Oil Seal 1002052027 is a genuine OEM component designed for superior sealing performance in heavy-duty diesel engines. This critical engine part, identified by reference number 1002052027, prevents oil leakage from the front crankshaft area while ensuring proper lubrication. Der 1002052027 oil seal maintains engine integrity and protects against costly repairs.

Engineered to meet Shacman’s rigorous quality standards, Die 1002052027 model features advanced sealing technology that withstands high rotational speeds and extreme temperature variations. Its precision design ensures optimal contact with the crankshaft, providing reliable performance under the most demanding operating conditions. Jede 1002052027 unit undergoes comprehensive testing for durability and functionality.

| Parameter | Wert |

|---|---|

| OEM Number | 1002052027 |

| Product Name | Front Crankshaft Oil Seal |

| Brand | Shacman |

| Seal Type | Radial Lip Seal with Garter Spring |

| Outer Diameter | 98 mm |

| Inner Diameter | 72 mm |

| Breite | 12 mm |

| Material | FKM Fluoroelastomer with Steel Case |

| Temperature Range | -40°C to 200°C |

| Compatibility | Shacman F3000, M3000 Series Engines |

Der 1002052027 features an optimized dual-lip sealing system with integrated garter spring. The primary lip maintains constant contact with the crankshaft surface under all operating conditions. This advanced design ensures minimal friction while providing maximum sealing efficiency.

Manufactured from FKM fluoroelastomer compound, Die 1002052027 offers exceptional resistance to engine oils, synthetic lubricants, and extreme temperatures. The reinforced steel casing provides dimensional stability and secure installation in the timing cover housing.

Der 1002052027 effectively prevents oil leakage from the front crankshaft area, maintaining proper oil pressure throughout the engine. This reliable sealing performance ensures adequate lubrication for all critical engine components and prevents costly damage.

The seal’s advanced design prevents dirt, Staub, and other external contaminants from entering the engine oil system. This protection extends the life of crankshaft bearings, timing gears, and other vital engine components.

Der 1002052027 is specifically engineered for Shacman F3000 and M3000 series trucks with various diesel engine configurations. This front crankshaft oil seal fits precisely in the timing cover housing location. Proper installation ensures optimal performance and longevity.

Compatibility extends to multiple engine models within the Shacman heavy-duty lineup. The seal accommodates different crankshaft diameters and rotational speeds while maintaining consistent sealing performance under varying operating conditions.

Clean the timing cover housing bore thoroughly before installation. Remove any old seal residue completely using appropriate tools. Lubricate the seal lip with clean engine oil. Use proper installation tools to avoid damaging the sealing surface.

Never install the seal dry or without proper lubrication. Avoid scratching the crankshaft sealing surface during installation. Check for proper orientation before final seating. Verify the seal sits flush with the housing surface after installation.

Regular inspection during engine maintenance is essential for optimal performance. Check for oil leakage around the front crankshaft area during routine service intervals. Look for signs of seal wear, hardening, or lip damage that may indicate replacement is needed.

Monitor engine oil levels and pressure regularly as unexpected changes may indicate seal issues. Use only genuine Shacman replacement parts to ensure perfect compatibility and performance. Proper maintenance prevents unexpected engine failures.

Der 1002052027 maintains sealing integrity in high-temperature environments up to 200°C. The FKM fluoroelastomer material resists hardening, cracking, and degradation under extreme heat stress. This reliability is crucial for heavy-duty engine performance.

In freezing conditions as low as -40°C, the seal remains flexible and fully functional. The advanced material properties prevent brittleness and maintain sealing capability at low temperatures. This ensures reliable engine operation during winter months.

Every 1002052027 seal undergoes rigorous quality control testing at multiple stages of production. Dimensional accuracy is verified using precision measuring equipment with micron-level tolerance. Lip tension and spring force are tested for consistency across all production batches.

The manufacturing process adheres to strict quality protocols with continuous monitoring. Material composition is analyzed using advanced laboratory equipment to ensure compliance with specifications. Each production batch undergoes extensive sample testing for performance validation.

The genuine 1002052027 outperforms aftermarket alternatives in multiple critical aspects. It offers superior sealing efficiency and significantly longer service life under identical operating conditions. Material quality and manufacturing precision exceed generic seal standards.

Independent testing demonstrates better resistance to wear, temperature extremes, and chemical degradation. The genuine part maintains lip integrity under pressure variations and rotational stresses that cause aftermarket seals to fail prematurely.

Using genuine 1002052027 seals provides significant long-term cost benefits for fleet operators. Extended service life reduces replacement frequency and associated labor costs. Reliability prevents expensive engine repairs and unplanned downtime that impact operational efficiency.

Improved fuel efficiency results from maintaining proper engine sealing and oil pressure. Reduced maintenance requirements increase vehicle availability and utilization rates. The initial investment in genuine parts delivers excellent return through extended service intervals.

Der 1002052027 serves various heavy-duty applications across multiple industries requiring reliable engine performance. Construction equipment operators depend on its durability in demanding site conditions. Mining operations demand its consistent performance in abrasive environments.

Logistics and transportation companies specify this genuine component for their fleet maintenance programs. Municipal vehicle fleets benefit from its proven reliability in diverse operating conditions. The seal performs excellently across all commercial applications.

Der 1002052027 typically provides extended service life exceeding 300,000 kilometers under normal operating conditions. Proper installation techniques and regular maintenance maximize its operational lifespan. Harsh operating environments may require earlier replacement based on inspection findings.

Regular inspections during routine maintenance help identify early signs of wear or deterioration. Replacement during major engine service intervals is recommended practice. The seal shows visible indicators when approaching the end of its service life.

Replace during major engine overhaul or when oil leakage is detected. Regular inspection during routine maintenance helps identify early replacement needs.

Never reuse crankshaft oil seals after removal. Always install new 1002052027 seals during engine service to ensure proper sealing performance.

Use clean engine oil or specified assembly lubricant. Apply lightly to the seal lip and crankshaft surface before installation to prevent dry startup.

Look for clear OEM numbering and authentic Shacman branding. Purchase only from authorized distributors to ensure product authenticity and warranty coverage.

Improper installation, crankshaft surface damage, contamination during installation, and misalignment are primary causes. Follow manufacturer procedures carefully.

The Shacman Front Crankshaft Oil Seal 1002052027 represents the highest standard in engine sealing technology for heavy-duty commercial vehicles. It provides reliable performance and superior protection for critical engine components. Using genuine OEM parts ensures optimal engine operation, Langlebigkeit, und Betriebseffizienz.

We recommend the 1002052027 for all compatible Shacman trucks and engines. It offers outstanding value through extended durability and consistent performance. Proper installation techniques and regular maintenance are essential for achieving maximum service life. This component supports efficient, zuverlässig, and cost-effective commercial vehicle operations.