- Willkommen bei der Shaanxi Automobile Group

- Webseite:www.shacman3000.com

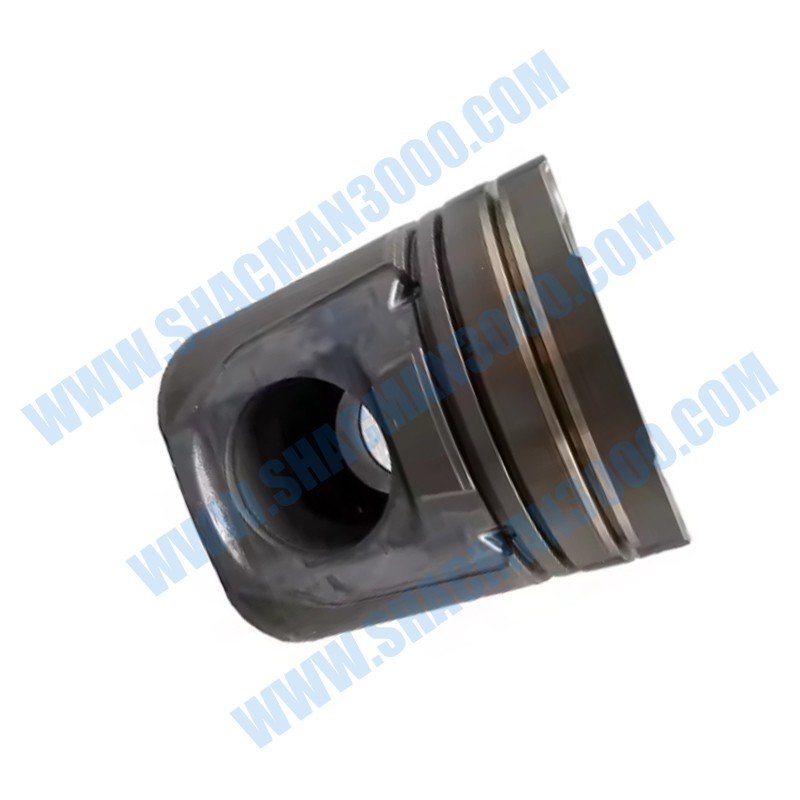

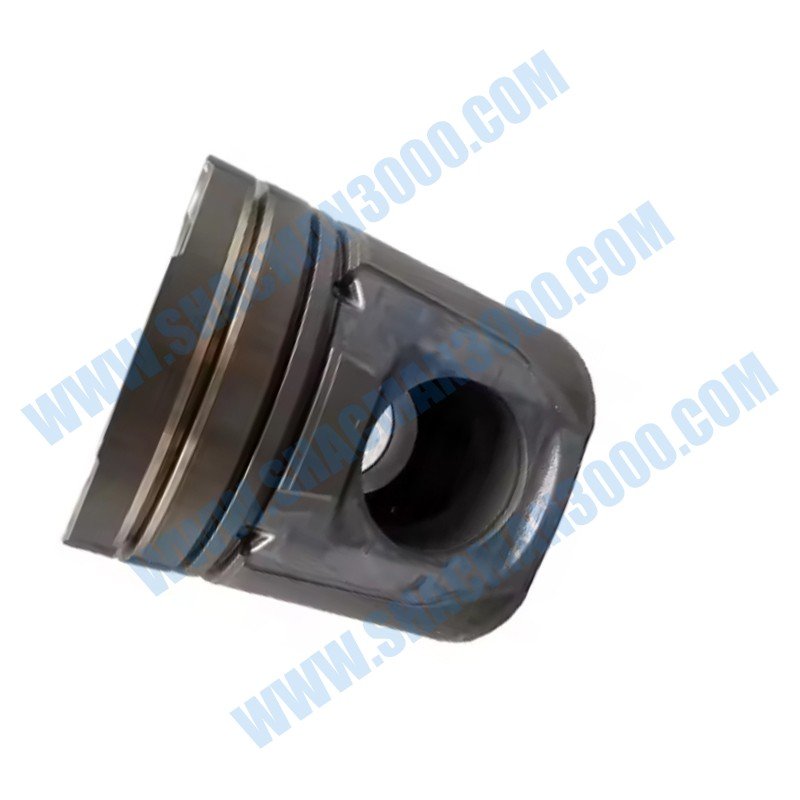

The WP12 Euro 5 Piston with OEM numbers 612630020024 Und 612630020152 represents the pinnacle of engine component technology for Shacman trucks. This high-performance piston is engineered specifically for Euro 5 emission standards, delivering exceptional durability and efficiency. The advanced design incorporates specialized materials and manufacturing processes that ensure optimal combustion performance while reducing harmful emissions. These pistons are crucial for maintaining engine integrity and performance in demanding operating conditions. With part numbers 612630020024/612630020152, Shacman owners can trust they’re getting genuine quality components that meet rigorous international standards.

Designed for the powerful WP12 engine series, these pistons feature innovative cooling galleries and reinforced skirt designs that withstand extreme pressures and temperatures. The precision engineering ensures perfect fitment and reliable operation across thousands of hours of service. The Euro 5 compliance means these pistons contribute to cleaner exhaust emissions while maintaining powerful performance characteristics. Regular maintenance with genuine 612630020024/612630020152 pistons helps prevent engine downtime and costly repairs. The thermal management properties of these components significantly extend engine life and improve fuel economy.

| Parameter | Wert |

|---|---|

| OEM Numbers | 612630020024/612630020152 |

| Product Name | WP12 Euro 5 Kolben |

| Brand | Shacman |

| Engine Compatibility | WP12 Series Euro 5 |

| Material | High-Strength Aluminum Alloy |

| Diameter | 126mm ±0.02mm |

| Compression Height | 72.5mm |

| Weight | Approx. 1.8 kg |

| Operating Temperature Range | -50°C to 350°C |

| Surface Treatment | Anodized Coating |

The WP12 Euro 5 Piston incorporates multiple advanced features that ensure superior engine performance and longevity. The optimized crown design promotes efficient fuel combustion while minimizing emissions. Integrated cooling galleries provide exceptional heat dissipation, preventing thermal deformation under high loads. The reinforced skirt design maintains structural integrity during intense operation cycles. Special ring groove treatments reduce carbon buildup and extend ring life. These features collectively contribute to the piston’s outstanding durability and performance characteristics in demanding applications.

The innovative cooling gallery design allows efficient oil circulation around the piston crown, significantly reducing operating temperatures. This thermal management system prevents hot spots that can lead to premature failure. The controlled temperature distribution ensures consistent expansion characteristics throughout operation. This feature is particularly crucial for maintaining performance during extended high-load operations. The result is extended component life and reduced maintenance requirements for Shacman WP12 engines.

Specially engineered for Euro 5 emission standards, these pistons feature optimized combustion chamber designs that reduce particulate matter and NOx emissions. The precise fuel mixing characteristics ensure complete combustion while minimizing environmental impact. The piston’s geometry works harmoniously with advanced injection systems to meet stringent regulatory requirements. This compliance makes the 612630020024/612630020152 pistons ideal for regions with strict emission controls.

Utilizing genuine WP12 Euro 5 Pistons provides numerous performance advantages for Shacman truck operators. The improved combustion efficiency translates to better fuel economy and reduced operating costs. Enhanced durability means fewer engine overhauls and increased vehicle uptime. The precise manufacturing tolerances ensure optimal engine compression and power output. These benefits combine to deliver superior return on investment through extended service intervals and reliable operation.

The optimized piston design promotes more complete fuel combustion, resulting in significant fuel savings over time. The reduced friction characteristics minimize energy losses within the engine. Proper piston-to-cylinder clearance maintains optimal thermal efficiency throughout the operating range. These efficiency improvements can reduce fuel consumption by 3-5% compared to standard pistons. The economic benefits quickly offset the initial investment in quality components.

Manufactured from premium aluminum alloys with advanced heat treatment, these pistons withstand extreme engine conditions. The robust construction resists cracking and deformation under high-pressure operation. The specialized skirt coating reduces wear and extends service life significantly. Proper maintenance with these pistons can extend engine overhaul intervals by thousands of operating hours. This durability translates to reduced total cost of ownership.

The WP12 Euro 5 Piston is designed for various heavy-duty applications across multiple industries. These pistons are ideal for long-haul transportation, construction equipment, Bergbauoperationen, and agricultural machinery. Their robust construction makes them suitable for both on-road and off-road applications. The emission compliance ensures they meet regulatory requirements in diverse geographical markets. Whether for freight transport or industrial use, these pistons deliver reliable performance.

In commercial fleet operations, these pistons provide the reliability needed for schedule adherence and cost control. Their compatibility with WP12 engines makes them essential for maintaining Shacman truck performance. The fuel efficiency benefits directly impact operational profitability for transport companies. The extended service intervals reduce maintenance downtime, increasing vehicle availability. These factors make them valuable for logistics and distribution operations.

For construction and mining applications, the pistons’ durability under extreme conditions ensures continuous operation. The high-load capability makes them suitable for equipment operating in challenging environments. The thermal management features prevent failures during intensive work cycles. This reliability is crucial for projects with tight deadlines and high equipment utilization rates. The pistons contribute to reduced equipment downtime in critical operations.

Proper installation of WP12 Euro 5 Pistons requires careful attention to technical specifications and procedures. Always begin with a clean work environment and appropriate tools. Measure cylinder bore dimensions to ensure proper clearance specifications are maintained. Use genuine replacement components and follow torque specifications precisely. Lubricate all moving parts with recommended engine oil during assembly. Following these guidelines ensures optimal performance and longevity.

Before installation, verify piston dimensions match engine requirements. Inspect for any shipping damage or manufacturing defects. Ensure ring gaps are properly set according to specifications. Check piston pin fitment and connecting rod alignment. Clean all components thoroughly to prevent contamination. These preliminary steps prevent installation errors and ensure reliable operation.

Regular maintenance is essential for maximizing WP12 Euro 5 Piston performance and service life. Monitor engine oil quality and change intervals to prevent contamination. Conduct regular compression tests to detect wear patterns early. Inspect piston components during scheduled maintenance intervals. Use recommended fuels and lubricants to maintain optimal operating conditions. These practices help identify potential issues before they cause significant damage.

Implement regular oil analysis to monitor engine condition and component wear. Schedule inspections based on operating hours rather than just mileage. Maintain proper engine cooling system operation to prevent overheating. Keep accurate service records to track component performance over time. These preventive measures extend piston life and prevent unexpected failures.

Shacman maintains rigorous quality control standards for all WP12 Euro 5 Pistons. Each component undergoes multiple inspection stages throughout manufacturing. Advanced testing procedures verify material properties and dimensional accuracy. Performance validation ensures compliance with international quality standards. The traceability system tracks each piston through production and distribution. This commitment to quality guarantees reliable performance in all applications.

State-of-the-art manufacturing facilities employ precision machining and automated processes. Advanced metallurgical controls ensure consistent material properties. Each piston undergoes non-destructive testing to detect potential defects. The manufacturing process incorporates continuous improvement based on field performance data. This excellence in production delivers components that exceed customer expectations.

The WP12 Euro 5 Piston with OEM numbers 612630020024 Und 612630020152 represents the ideal choice for Shacman truck owners seeking reliable engine performance. The advanced design features and manufacturing quality ensure exceptional durability and efficiency. The emission compliance makes these pistons suitable for modern environmental requirements. The performance benefits translate to tangible operational cost savings. Investing in genuine Shacman components guarantees compatibility and reliability.

Proper installation and maintenance of these pistons ensure long-term engine health and performance. The quality assurance processes provide confidence in component reliability. The versatile applications make them suitable for various industries and operating conditions. Choosing genuine 612630020024/612630020152 pistons protects your investment in Shacman equipment. This commitment to quality components supports sustainable and profitable operations.