Caliper Repair Kit Rear

Ремонтный комплект суппорта заднего

Kit de Reparación de Pinza Trasera

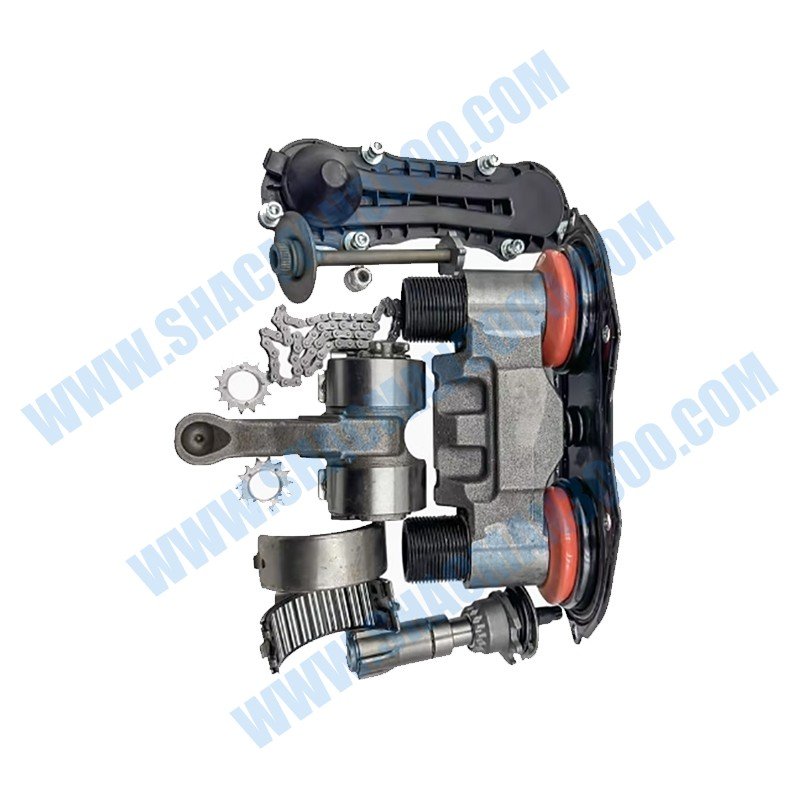

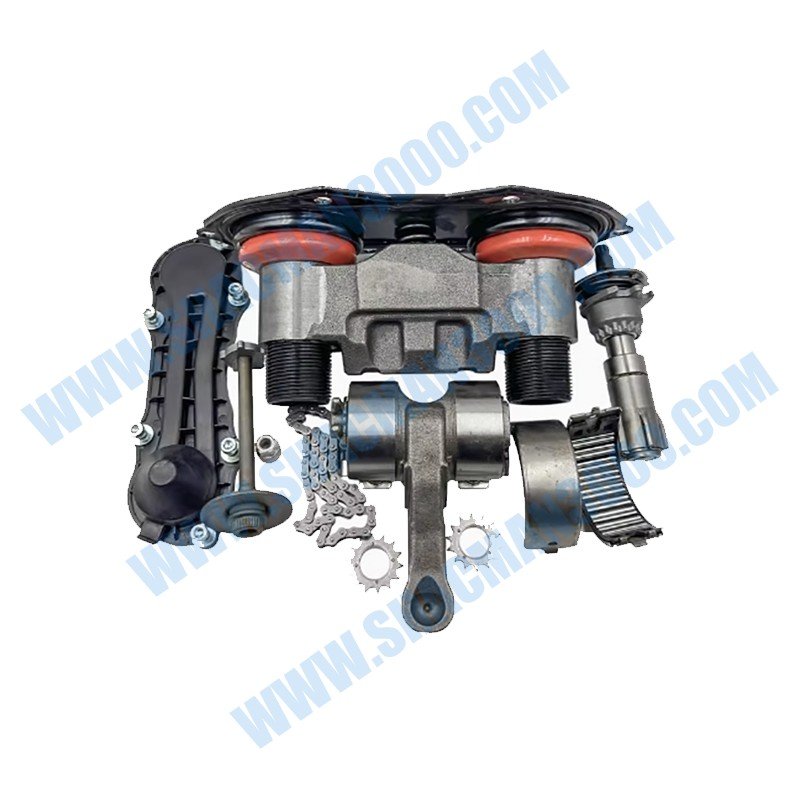

The genuine Shacman Caliper Repair Kit Rear with OEM number HD90129340673-XLB delivers exceptional brake system maintenance performance for heavy-duty truck rear braking applications. This comprehensive repair kit contains all necessary components for professional rear brake caliper service and restoration, ensuring reliable braking performance.

Manufactured to exact OEM specifications using premium materials, the HD90129340673-XLB rear caliper repair kit provides reliable performance and extended service life. The precision engineering guarantees perfect fitment and optimal braking performance for Shacman rear brake caliper systems in various operating conditions.

With high-quality seals, pistons, and hardware components specifically designed for rear brake applications, this repair kit offers superior durability and corrosion resistance. Professional maintenance with genuine components ensures optimal rear brake system function and prevents costly brake system failures.

| Parameter | Specification |

|---|---|

| OEM Part Number | HD90129340673-XLB |

| Product Name | Caliper Repair Kit Rear |

| Brand | Shacman |

| Kit Type | Complete Rear Repair Kit |

| Seal Material | High-Grade EPDM Rubber |

| Piston Material | Corrosion-Resistant Steel |

| Operating Temperature | -40°C to +180°C |

| Pressure Rating | 180 Bar Maximum |

| Compatibility | Shacman Rear Brake Calipers |

The Shacman Caliper Repair Kit Rear provides a comprehensive solution for rear brake caliper maintenance and restoration. This complete kit includes all necessary components specifically designed for rear brake system service and repair requirements.

Advanced sealing technology ensures proper hydraulic pressure maintenance and prevents brake fluid leakage in rear braking systems. The design guarantees reliable braking performance and extended rear caliper service life.

Manufactured from high-grade EPDM rubber and corrosion-resistant steel components, this rear repair kit offers excellent resistance to wear and environmental factors. The robust materials withstand demanding rear braking conditions.

Advanced material formulations provide superior resistance to brake fluid, heat cycling, and mechanical stress. The durable design ensures long-term reliability and consistent rear brake performance.

Each HD90129340673-XLB rear caliper repair kit undergoes rigorous quality control procedures throughout manufacturing. Precise dimensional accuracy guarantees perfect fitment without modifications for rear brake applications.

Computer-aided design and manufacturing processes ensure consistent product quality and performance. Engineering specifications meet original equipment requirements for rear brake system reliability.

This genuine Shacman component is specifically engineered for rear brake caliper applications in heavy-duty trucks. The repair kit ensures optimal performance across various vehicle configurations and rear axle systems.

Proper installation maintains factory specifications for rear braking efficiency and hydraulic performance. Vehicle operators can expect reliable rear braking performance and enhanced vehicle stability.

The Caliper Repair Kit Rear performs reliably in diverse environmental conditions and braking scenarios specific to rear axle applications. From load balancing to parking brake functions, these components maintain system integrity.

The design accounts for rear brake specific requirements, including parking brake mechanisms and different pressure characteristics. Various transportation applications benefit from this durable rear brake repair solution.

Shacman implements stringent quality control measures throughout the entire production process for rear brake components. Each repair kit undergoes multiple inspection stages before packaging.

Advanced testing equipment verifies dimensional accuracy, material properties, and performance characteristics specific to rear brake applications. The manufacturing facility maintains ISO certification.

Comprehensive laboratory testing simulates real-world rear brake operating conditions to ensure reliability. Pressure and durability testing exceeds standard requirements for safety margins.

Environmental testing verifies performance under extreme temperature and humidity conditions specific to rear brake locations. The results confirm the product’s capability in demanding applications.

Proper installation requires professional tools and technical expertise for optimal results in rear brake systems. Technicians should follow manufacturer-recommended procedures during brake system service.

Rear brake components must be thoroughly cleaned and inspected before installation. Professional installation ensures proper sealing and prevents hydraulic system issues in rear brake applications.

Regular rear brake system inspections during routine maintenance help identify potential issues early. Check for signs of fluid leakage or component wear during scheduled service intervals.

Brake fluid quality and level should be maintained according to manufacturer specifications. Rear caliper service is recommended when inspection reveals seal deterioration or performance issues.

The optimized design ensures reliable hydraulic performance for consistent rear braking operation. Properly functioning rear caliper components prevent brake drag and uneven pad wear patterns.

The component’s sealing efficiency contributes to stable brake pressure and balanced braking between axles. This protects overall brake system performance and extends component lifespan.

Maintaining proper rear brake caliper function directly impacts vehicle operating costs and safety compliance. Effective repair solutions reduce the need for complete rear caliper replacement.

The precise engineering minimizes brake fluid consumption and system maintenance requirements for rear brakes. This contributes to reduced operating costs and improved vehicle efficiency.

Shacman stands behind the quality of every genuine component manufactured. The Caliper Repair Kit Rear comes with comprehensive warranty coverage for customer assurance and peace of mind.

This commitment reflects the manufacturer’s confidence in product reliability and performance for rear brake applications. Customers receive full support for any manufacturing defects identified.

Professional technical assistance remains available for installation guidance and troubleshooting needs specific to rear brake systems. Shacman’s network provides expert support when required.

Comprehensive documentation accompanies each product for reference and guidance. Customers can access additional resources through authorized service centers worldwide.

Regular inspection during scheduled maintenance helps identify rear caliper wear before performance degradation occurs. Visual checks should include seal condition and piston operation assessment.

Repair timing depends on driving conditions, brake usage patterns, and environmental factors affecting rear brakes. Severe service applications may require more frequent inspection intervals.

Professional installation by qualified technicians ensures optimal performance and safety compliance for rear brake systems. Certified workshops have proper equipment for correct brake system service.

Proper brake system bleeding and pressure testing are essential after rear brake repair. This ensures the hydraulic system functions as designed by the manufacturer for safe operation.

All raw materials undergo rigorous certification processes before production begins for rear brake components. Rubber compounds meet automotive standards for brake system applications.

Metal components and hardware are tested for strength and corrosion resistance specific to rear brake environments. Material traceability ensures consistent quality across production batches.

State-of-the-art manufacturing equipment ensures precision and consistency in production for rear brake components. Automated processes maintain tight tolerances and dimensional accuracy.

Each production stage includes quality checks and verification procedures. Final inspection confirms all specifications are met before packaging and shipping to customers.

Ideal for long-haul trucks operating under continuous heavy loads with frequent braking requirements on rear axles. The repair kit provides reliable maintenance solutions for vehicles in demanding transportation.

The component maintains rear brake system integrity during extended highway operation and varied load conditions. Fleet operators benefit from consistent performance across different operating scenarios.

Essential for equipment operating in demanding environments where rear brake reliability is critical for safety and operational efficiency. The robust design handles challenging operating conditions.

Mining applications benefit from the component’s resistance to contamination, dust, and harsh environments affecting rear brakes. The durable construction ensures reliable brake system performance.

Proper rear brake system maintenance with genuine components significantly extends overall system operational lifespan. Effective caliper repair reduces wear on related rear brake components.

The repair kit’s durable construction contributes to overall braking reliability and longevity for rear axle systems. This translates to extended service life and improved return on investment.

Maintaining optimal rear brake caliper performance ensures consistent braking and vehicle stability during operation. Reliable rear hydraulic systems enhance safety in various driving situations.

The component’s precision engineering ensures reliable performance throughout its service life. Vehicle operators experience consistent and balanced brake operation between axles.

Genuine Shacman components provide optimal protection that reduces long-term maintenance costs for rear brake systems. Preventing complete rear caliper replacement offers significant economic benefits.

The initial investment in quality repair parts pays dividends through extended service intervals and reduced downtime. Fleet managers appreciate the predictable maintenance costs and reliability.

Reliable rear brake components contribute to overall vehicle uptime and operational safety compliance. This ensures business continuity and regulatory compliance for commercial operators.

The proven performance of genuine Shacman parts provides confidence in vehicle safety and reliability. Operators can depend on consistent rear brake system performance in all conditions.

Always verify part number HD90129340673-XLB before purchase to ensure compatibility with your specific vehicle rear brake caliper system requirements and configurations.

Genuine Shacman parts meet exact engineering specifications and performance requirements for optimal vehicle safety and rear braking efficiency in various applications.

Professional installation and regular maintenance inspections are essential for achieving optimal performance and ensuring rear brake system integrity is maintained throughout service life.