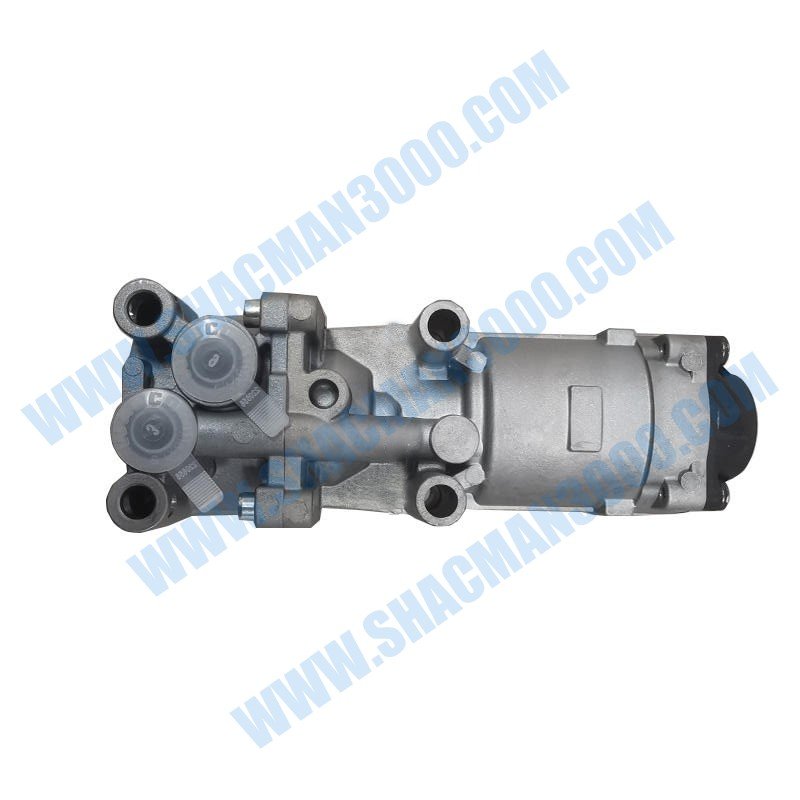

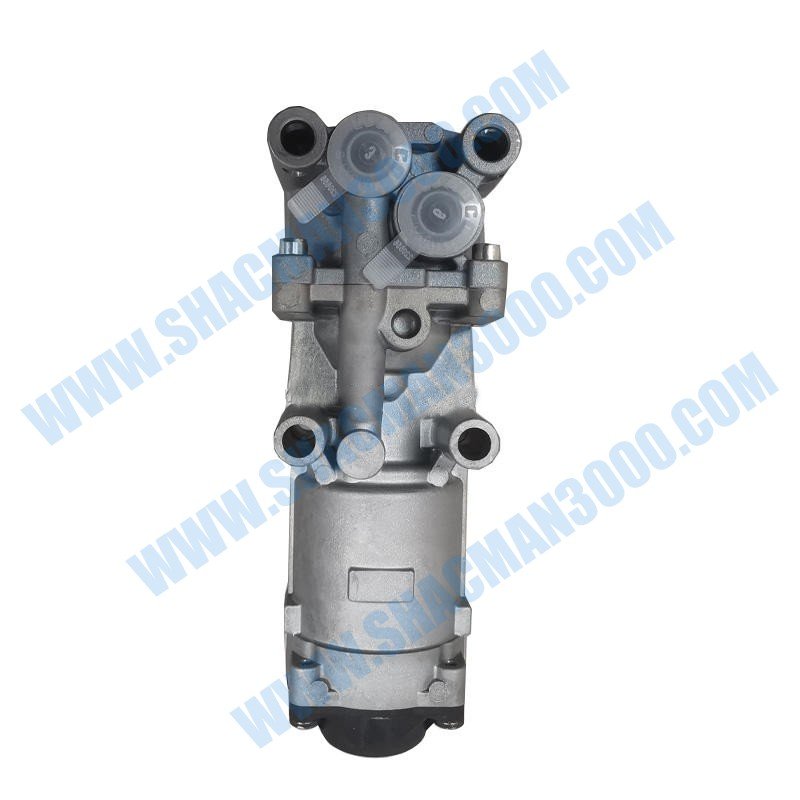

The HB400-6001 Electrovalvula Retardador represents cutting-edge auxiliary braking technology specifically engineered for Shacman commercial trucks. This genuine OEM retarder solenoid valve with reference number HB400-6001 delivers superior braking performance and enhanced vehicle safety for heavy-duty applications.

Manufactured with precision engineering and advanced electromagnetic technology, this retarder solenoid valve ensures reliable hydraulic control and consistent braking force modulation. The component features robust construction that withstands demanding operating conditions while maintaining optimal performance throughout extended service periods.

| Parameter | Specification |

|---|---|

| OEM Number | HB400-6001 |

| Product Name | Electrovalvula Retardador |

| Brand | Shacman |

| Valve Type | Solenoid Control Valve |

| Operating Voltage | 24V DC |

| Current Consumption | 1.2A Max |

| Pressure Rating | 25 Bar Maximum |

| Response Time | ≤ 50 ms |

| Operating Temperature | -40°C to 125°C |

| Weight | 1.8 kg |

| Compatible Models | Shacman X3000, F3000 Series |

The HB400-6001 retarder solenoid valve features advanced electromagnetic technology for precise hydraulic control. This sophisticated system ensures accurate modulation of retarder braking force during vehicle operation.

High-precision coil winding provides consistent magnetic field strength and reliable valve actuation. The design ensures rapid response times and stable performance under varying electrical conditions.

Optimized internal passage design ensures efficient hydraulic fluid flow with minimal pressure drop. The valve maintains consistent performance across the entire operating pressure range.

Precision-machined spool and sleeve components provide smooth operation and precise flow control. The design minimizes internal leakage and ensures reliable hydraulic circuit isolation.

High-strength aluminum alloy housing provides excellent durability and heat dissipation. The material withstands harsh environmental conditions and mechanical stress.

Premium sealing materials ensure reliable operation and prevent hydraulic fluid leakage. All components meet strict quality standards for commercial vehicle applications.

The Electrovalvula Retardador delivers significant performance benefits for commercial vehicle braking systems. Enhanced retarder control ensures superior vehicle stability and braking efficiency.

Reduced service brake wear extends the lifespan of primary braking components. The auxiliary braking system provides consistent performance during extended downhill operations.

Superior response characteristics handle the demanding requirements of heavy-duty truck applications. The valve operates reliably in extreme temperatures and challenging environmental conditions.

The retarder system provides additional braking capacity without relying on friction components. This reduces the risk of brake fade during prolonged downhill descents.

Precise control ensures smooth and predictable retarder engagement. The system maintains vehicle stability and prevents wheel lock-up during auxiliary braking operations.

Premium materials and precision manufacturing ensure long-term reliability and consistent performance. The solenoid valve withstands continuous electrical and hydraulic cycling.

Advanced corrosion protection ensures reliable operation in harsh environmental conditions. The component maintains structural integrity throughout its designed service interval.

The HB400-6001 retarder solenoid valve is specifically engineered for Shacman X3000 and F3000 series trucks. The component ensures perfect compatibility with designated retarder system configurations.

Mounting points and connection interfaces match original equipment specifications precisely. No modifications or adaptations are required for proper installation and operation.

Comprehensive compatibility testing verifies performance across different model variants and production years. Fleet operators can standardize on this component across their vehicle inventory.

The retarder solenoid valve is designed for efficient installation by qualified technicians. All necessary mounting hardware and connection components are included for complete replacement.

Clear installation guidelines ensure proper alignment and secure attachment. The process typically requires standard automotive tools and can be completed within reasonable timeframes.

Proper electrical connections ensure optimal performance and prevent voltage drop issues. All terminals must be clean and properly torqued according to specifications.

Correct wiring routing prevents chafing and electrical shorts. The installation should include proper insulation and protection of all electrical connections.

The solenoid valve assembly maintains optimal hydraulic pressure for efficient retarder operation. Advanced pressure regulation ensures proportional braking force application.

Precise flow control prevents hydraulic shock and maintains system stability. The design accommodates varying fluid viscosity and temperature conditions.

Proper hydraulic management contributes to reduced component stress and extended system life. The valve minimizes the risk of pressure spikes and performance degradation.

The solenoid valve features precisely engineered electrical connectors that ensure perfect integration with vehicle wiring systems. All connections are designed for reliable current transmission.

Advanced coil design prevents voltage fluctuations and ensures stable magnetic field generation. The electrical system maintains compatibility with standard vehicle electrical configurations.

Built-in protection systems prevent electrical overload and short-circuit scenarios. The solenoid assembly includes proper grounding and insulation for maximum electrical safety.

All electrical components meet automotive safety standards and undergo rigorous testing for reliability. The design incorporates thermal protection mechanisms for extended operation.

Every HB400-6001 retarder solenoid valve undergoes comprehensive quality control testing during manufacturing. The testing process includes electrical verification, pressure testing, and durability assessments.

All components meet or exceed original equipment specifications and industry standards. The manufacturing process follows strict quality management protocols to ensure consistent product excellence.

Final inspection includes visual examination, functional testing, and packaging verification. Each valve is individually tested before shipment to ensure perfect performance.

Regular visual inspection of the solenoid valve during routine maintenance intervals. Check for any signs of hydraulic leakage, corrosion, or physical damage to connections.

Periodic inspection of mounting hardware ensures secure attachment and proper alignment. Check electrical connections for tightness and corrosion during scheduled maintenance.

Monitor retarder performance for any unusual operation or delayed response times. Unusual operational characteristics should be investigated promptly by qualified technicians.

Verify proper valve operation and electrical response during normal operation. Any performance deviations should be addressed immediately to maintain safety standards.

Each retarder solenoid valve is individually packaged in protective materials to prevent damage during shipping. Specialized cushioning protects the electrical components and hydraulic ports.

Packaging design ensures safe transportation via various logistics methods. Clear labeling identifies the contents and provides handling instructions for warehouse personnel.

Bulk shipments include additional protective measures and secure palletization. The packaging meets international shipping standards for automotive components.

The HB400-6001 retarder solenoid valve offers exceptional value through superior performance and extended service life. Genuine OEM quality ensures perfect compatibility and reliable operation.

Competitive pricing combined with premium features provides outstanding return on investment. The valve delivers long-term cost savings through reduced maintenance requirements.

Enhanced braking performance contributes to improved vehicle safety and reduced operating costs. The component supports overall vehicle reliability and operational efficiency.

Fleet operators benefit from reduced maintenance costs and extended service intervals. The reliable performance minimizes vehicle downtime and maximizes operational efficiency.

Individual truck owners enjoy peace of mind knowing their vehicles are equipped with genuine OEM components. The retarder solenoid valve maintains vehicle value and ensures consistent performance.

All users benefit from enhanced braking reliability and improved vehicle safety. The superior design reduces the risk of braking failures and associated operational hazards.

The advanced retarder system contributes to overall vehicle operational efficiency. Improved braking control allows for better vehicle handling and reduced wear on service brakes.

Reduced maintenance requirements minimize vehicle downtime and repair costs. The efficient design contributes to better overall vehicle economy and reduced operating expenses.

Long service life and reliable performance reduce the total cost of ownership. Fewer replacements and maintenance requirements translate to better operational economics.

High-strength materials provide excellent durability and corrosion resistance. The components maintain structural integrity under extreme operating conditions.

Premium electromagnetic materials ensure optimal magnetic performance and thermal stability. The materials are specifically selected for heavy-duty automotive applications.

Computer-controlled manufacturing ensures perfect dimensional accuracy and compatibility. Advanced engineering techniques guarantee consistent quality across all production units.

Rigorous testing protocols verify performance under simulated operating conditions. Each valve meets strict quality standards before shipment to customers.

The HB400-6001 Electrovalvula Retardador represents the optimal retarder control solution for Shacman truck operators seeking genuine OEM performance. This solenoid valve combines advanced electromagnetic technology with rugged construction for superior reliability and long-term durability.

Fleet managers and maintenance professionals can depend on this component for consistent performance and straightforward installation. The valve meets all original equipment specifications while providing enhanced braking control and safety benefits for commercial vehicle operations in demanding conditions.