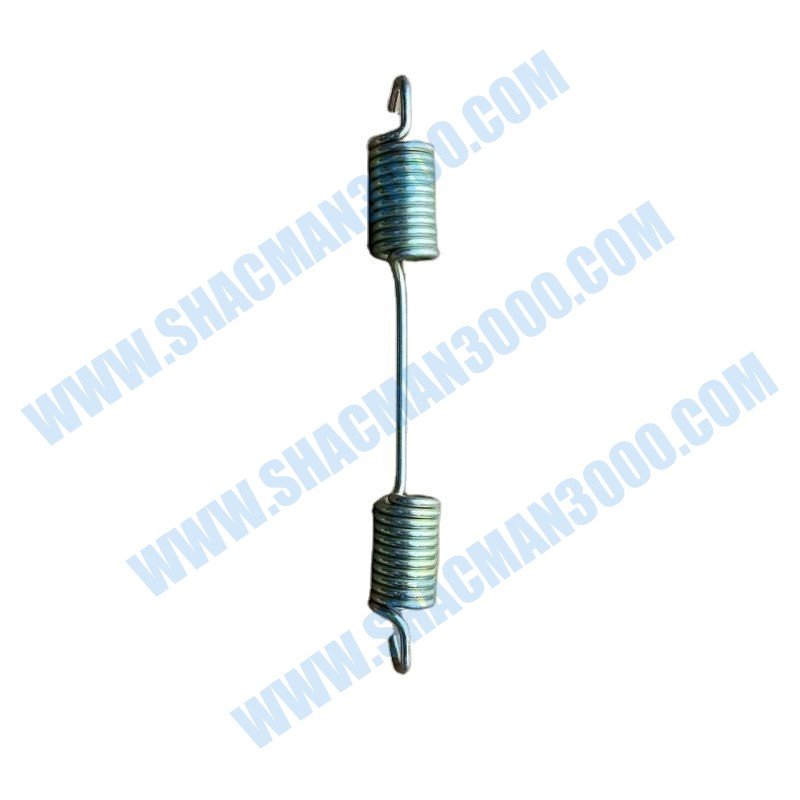

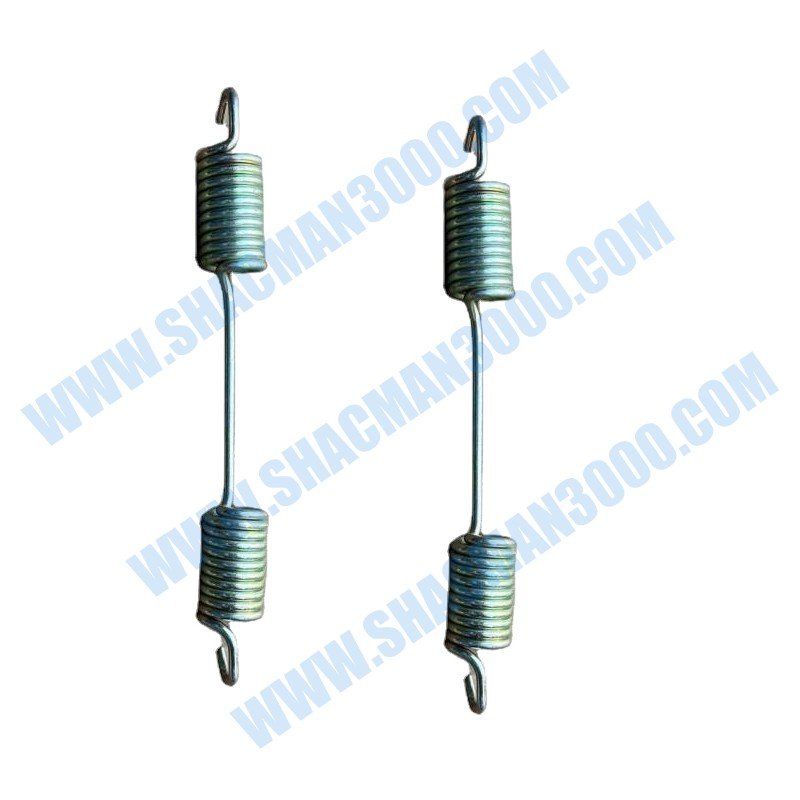

Return Spring

Возвратная пружина

Resorte de Retorno

The Shacman Return Spring with OEM number DZ95009440015 delivers exceptional mechanical performance and reliability in commercial vehicle applications. This critical component ensures precise return motion and consistent operation across various mechanical systems in Shacman trucks. Engineered specifically for heavy-duty transportation requirements, the DZ95009440015 model provides superior fatigue resistance and long-lasting durability. The spring’s advanced design maintains consistent force characteristics throughout its service life, ensuring reliable performance in demanding operating conditions.

Manufactured using premium spring steel and precise heat treatment processes, this genuine Shacman component guarantees optimal compatibility with your vehicle’s mechanical systems. The return spring’s robust construction withstands repeated compression cycles and environmental challenges encountered in commercial trucking operations. Proper installation and maintenance of the DZ95009440015 ensure smooth system operation and prevent premature component wear. Fleet operators trust this spring for its proven reliability and cost-effective performance across diverse transportation applications.

| Parameter | Specification |

|---|---|

| OEM Number | DZ95009440015 |

| Product Name | Return Spring |

| Brand | Shacman |

| Compatible Models | Shacman F3000, M3000, X3000 Series |

| Material | High-Carbon Spring Steel |

| Wire Diameter | 4.5mm |

| Outer Diameter | 32mm |

| Free Length | 120mm |

| Spring Rate | 8.5 N/mm |

| Maximum Load | 450 N |

| Heat Treatment | Tempered and Stress-Relieved |

| Surface Treatment | Zinc Plated |

The Return Spring DZ95009440015 incorporates advanced engineering principles for superior mechanical performance in commercial vehicle applications. Its precision design ensures consistent force characteristics and reliable return motion across millions of operating cycles. The spring’s geometric configuration is optimized for optimal stress distribution and fatigue resistance. Advanced manufacturing techniques guarantee precise dimensional accuracy and consistent mechanical properties. The high-carbon spring steel material provides excellent elasticity and durability under repeated compression and extension cycles.

Another significant feature is the spring’s specialized heat treatment process that enhances material properties and service life. The tempering process relieves internal stresses and improves the steel’s toughness and flexibility. Stress-relieving treatments prevent premature failure and maintain consistent performance characteristics. The zinc plating surface treatment provides excellent corrosion resistance against moisture, road salts, and environmental factors. These engineering features combine to create a reliable mechanical component that meets the rigorous demands of commercial transportation.

Material selection for the DZ95009440015 follows rigorous testing protocols and international quality standards. The high-carbon spring steel exceeds automotive specifications for mechanical applications requiring durability and reliability. Chemical composition is precisely controlled to ensure optimal balance of strength, flexibility, and fatigue resistance. Each production batch undergoes comprehensive material certification for complete traceability and quality assurance. The manufacturing process incorporates statistical process control methods to maintain consistent quality across all production runs.

Proper installation of the Return Spring DZ95009440015 requires careful preparation and adherence to technical specifications. Begin by thoroughly cleaning the mounting area and inspecting for any damage or wear that could affect performance. Ensure the spring is properly aligned with its mounting points and operating mechanism. Use appropriate tools to compress the spring during installation, avoiding over-extension or twisting that could cause permanent deformation. Verify that the spring moves freely without binding or interference from surrounding components.

Regular maintenance ensures optimal performance and identifies potential issues before they affect system operation. Conduct visual inspections during routine service intervals, checking for signs of corrosion, deformation, or fatigue damage. Monitor spring performance by observing return motion consistency and checking for unusual noises or resistance. Measure free length periodically to detect any permanent set or loss of tension. Lubricate according to manufacturer recommendations if specified for your particular application. Replace springs showing signs of wear or performance degradation immediately.

Correct handling and installation techniques are essential for spring performance and service life. Always wear appropriate personal protective equipment when handling springs under tension. Use manufacturer-recommended tools for spring compression and installation to prevent damage. Avoid impact loading or sudden compression that could cause permanent deformation or cracking. Ensure proper alignment during installation to prevent side loading or twisting motions. Follow torque specifications and installation sequences precisely for optimal performance and safety.

The Return Spring DZ95009440015 complies with international automotive standards and quality requirements for mechanical components. The manufacturing process follows ISO 9001 quality management system requirements throughout production. Each component undergoes rigorous testing before shipment to validate performance characteristics and durability. Material specifications meet or exceed automotive OEM standards for spring applications in commercial vehicles. These compliance measures ensure the spring’s reliability and performance in demanding transportation applications.

Quality assurance processes guarantee consistent performance across all production batches and manufacturing cycles. Raw materials undergo thorough inspection for chemical composition and mechanical properties. Wire forming operations maintain precise dimensional control and surface quality standards. Heat treatment processes are carefully monitored and controlled for consistent results. Each completed spring undergoes load testing, dimensional verification, and visual inspection. Final quality checks include surface treatment evaluation and performance validation before packaging.

Every DZ95009440015 return spring undergoes comprehensive performance testing to ensure reliability and durability. Load testing verifies spring rate consistency and maximum load capacity under various conditions. Fatigue testing simulates years of service to validate long-term performance and cycle life. Dimensional testing confirms precise geometry and tolerance compliance for proper fitment. Corrosion testing evaluates surface treatment effectiveness and environmental resistance. These tests ensure reliable operation throughout the spring’s service life in commercial vehicle applications.

The Return Spring DZ95009440015 serves critical functions across various systems in Shacman commercial vehicles. Clutch systems utilize these springs for precise pedal return and smooth engagement characteristics. Brake mechanisms depend on them for consistent return motion and reliable operation. Throttle linkages employ return springs for responsive control and safety functions. Transmission systems incorporate them for shift mechanism operation and gear positioning. Various door and access mechanisms use return springs for smooth operation and secure closure.

Seating systems benefit from return springs for adjustment mechanisms and comfort features. Hood and access panel mechanisms utilize them for controlled movement and secure latching. The spring’s versatile design makes it suitable for multiple applications requiring precise return motion and consistent force characteristics. Different vehicle systems utilize specific spring configurations optimized for particular operational requirements and environmental conditions. The compatibility across Shacman truck models simplifies inventory management for fleet operators.

The DZ95009440015 is engineered to meet specific performance requirements across different vehicle systems. Clutch applications demand consistent return force for smooth pedal operation and driver comfort. Brake systems require reliable return motion for safety and regulatory compliance. Throttle mechanisms need precise spring characteristics for responsive engine control. Transmission applications benefit from durable performance under high-cycle conditions. Each application presents unique challenges that the spring’s design addresses through optimized material selection and manufacturing processes.

The Return Spring DZ95009440015 offers significant economic advantages for fleet operators and maintenance facilities. Its extended service life reduces replacement frequency and associated labor costs over the vehicle lifecycle. The durable construction minimizes unexpected failures that could lead to expensive vehicle downtime and repair costs. Reduced maintenance requirements lower overall operating expenses while increasing vehicle availability for revenue generation. The component’s reliable performance prevents collateral damage to more expensive system components.

Operational efficiency improvements contribute directly to profitability and effective cost management. Reduced mechanical system issues mean increased vehicle utilization and fewer operational disruptions. The standardized design simplifies technician training and streamlines maintenance procedures across diverse fleet operations. Bulk purchasing opportunities provide additional cost savings for fleet operators managing multiple vehicles. The long-term reliability fully justifies the initial investment in genuine OEM parts compared to alternative options.

Detailed cost analysis demonstrates the return spring’s exceptional economic value and attractive return on investment. Consider the extended service life compared to alternative products in similar mechanical applications. Calculate significant savings from reduced maintenance requirements and fewer emergency replacements over time. Factor in the operational benefits of improved vehicle availability and substantially reduced downtime costs. Include the substantial value of prevented damage to other system components that could result from spring failures.

The Return Spring DZ95009440015 utilizes state-of-the-art manufacturing technology and material science for superior performance. Advanced spring steel formulations provide optimal balance of strength, flexibility, and fatigue resistance. Precision coiling equipment ensures consistent geometry and mechanical properties across all production batches. Computer-controlled heat treatment processes deliver uniform material properties and enhanced durability. Automated surface treatment systems provide consistent corrosion protection and aesthetic quality.

Quality control systems incorporate advanced testing equipment and statistical analysis for process optimization. Spring rate testing verifies consistent force characteristics throughout the production range. Fatigue testing simulates years of service to validate long-term performance under realistic conditions. Environmental testing evaluates corrosion resistance and performance in various climatic conditions. Dimensional verification ensures precise fitment and compatibility with vehicle systems. These comprehensive measures ensure reliable performance throughout the spring’s service life.

The manufacturing process for DZ95009440015 incorporates advanced material processing techniques and quality validation methods. Spring steel wire undergoes precise drawing processes to achieve optimal surface finish and dimensional accuracy. Coiling operations maintain strict control over pitch, diameter, and overall geometry parameters. Heat treatment processes are carefully monitored using temperature profiling and atmosphere control systems. Surface treatment operations ensure complete coverage and consistent coating thickness for maximum corrosion protection.

Shacman incorporates comprehensive environmental responsibility into return spring design and manufacturing processes. The DZ95009440015 utilizes materials with enhanced recycling potential and reduced environmental impact. Manufacturing processes minimize waste generation through efficient material usage and advanced production optimization. Energy consumption during production is continuously monitored and systematically improved through efficiency measures. Packaging materials are selected for recyclability and reduced environmental footprint throughout the supply chain.

The product’s extended durability contributes significantly to resource conservation through longer service life and reduced replacement frequency. Proper maintenance practices further enhance environmental performance by maximizing service life and operational efficiency. The return spring can be responsibly recycled at end-of-life through appropriate channels and specialized processing methods. Shacman provides detailed guidance on responsible disposal practices and environmental stewardship principles for customers and service facilities.

The return spring manufacturing process emphasizes sustainability and environmental responsibility throughout all production stages. Energy-efficient equipment reduces the carbon footprint and minimizes environmental impact. Water-based surface treatment processes eliminate hazardous chemicals and reduce pollution. Material recycling programs ensure maximum utilization of resources and minimum waste generation. Continuous improvement initiatives focus on reducing energy consumption and environmental impact while maintaining product quality and performance standards.

The Shacman Return Spring DZ95009440015 represents engineering excellence in commercial vehicle mechanical components and systems. Its advanced design provides reliable return motion and consistent force characteristics across millions of operating cycles. The spring’s robust construction ensures exceptional durability and long-term performance in various applications and operating conditions. Comprehensive testing and certification guarantee full compliance with international quality and performance standards. Significant economic benefits include extended service life, reduced operating costs, and improved vehicle reliability. Choose this genuine Shacman component for enhanced mechanical system performance and proven durability in your commercial transportation operations and comprehensive fleet management strategies.