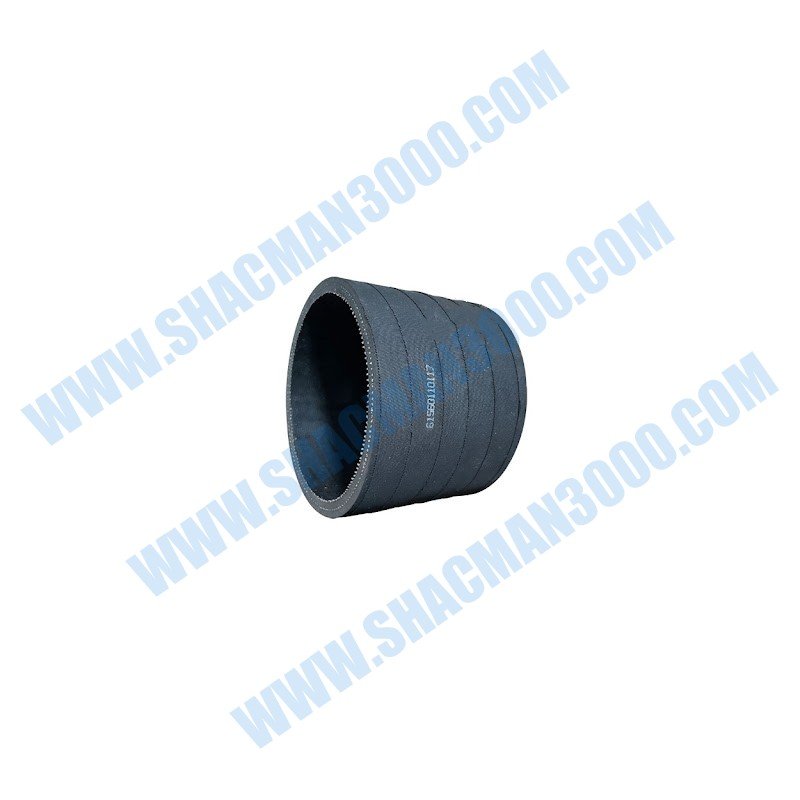

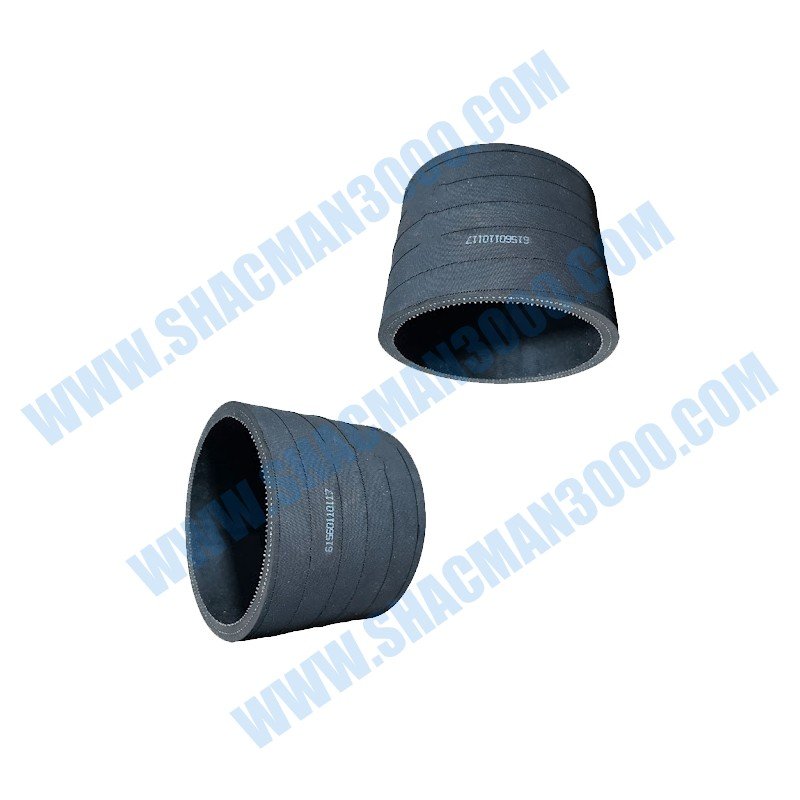

Air Connection Rubber Hose

Резиновый воздушный шланг

Manguera de Goma para Conexión de Aire

The Shacman Air Connection Rubber Hose BY61560110117 is a crucial, flexible conduit within the truck’s pneumatic system, designed to reliably transport compressed air between various components. This genuine OEM part, identified by the precise number BY61560110117, ensures a durable and airtight connection for applications such as air brake circuits, suspension controls, and auxiliary air-powered devices. A failure in this hose can lead to air leaks, pressure loss, and compromised system functionality, directly affecting vehicle safety and operational reliability. For Shacman trucks, using the correct, high-quality hose assembly is essential for maintaining consistent air pressure and preventing costly downtime. It is engineered to withstand constant pressure cycles, vibration, and environmental exposure.

Constructed from specialized synthetic rubber compounds and reinforced with high-tensile textiles, this hose offers superior flexibility, crack resistance, and longevity compared to generic alternatives. Its specific length, inner diameter, and end fittings are calibrated for exact fitment within Shacman’s air system architecture, guaranteeing optimal performance and leak-free operation under all driving conditions.

| Parameter | Specification / Value |

|---|---|

| OEM Part Number | BY61560110117 |

| Product Name | Air Connection Rubber Hose |

| Brand | Shacman |

| Primary Material | Synthetic Rubber (NBR, EPDM) with Textile Reinforcement |

| Inner Diameter (Approx.) | 10 mm – 14 mm (Model Specific) |

| Working Pressure | Up to 1.2 MPa (12 bar / 174 psi) |

| Temperature Range | -40°C to +100°C |

| End Fitting Type | Molded/ Crimped Brass or Steel Fittings |

| Compatible Systems | Air Brakes, Air Suspension, Cab Tilt, Auxiliary Air |

| Key Feature | Oil, Weather, and Ozone Resistant |

Modern heavy-duty trucks rely heavily on compressed air systems for safety and functionality. The air hose BY61560110117 acts as a vital artery within this network.

It transmits compressed air from the reservoir tanks to actuators, valves, and control modules. This includes critical functions like applying the service brakes and parking brakes.

Any leak or failure in this hose directly reduces the air pressure available for these systems. This can lead to delayed brake response or incomplete brake application.

Beyond braking, it may supply air for suspension leveling valves, cab tilt mechanisms, or pneumatic seat adjustments. A single hose failure can disable multiple vehicle features.

A small leak forces the air compressor to cycle more frequently to maintain system pressure. This increases fuel consumption and accelerates wear on the compressor.

Chronic low pressure can cause air-operated devices to function sluggishly or not at all. For example, a slow cab tilt mechanism is an operational nuisance and a safety risk.

In the brake system, pressure loss increases stopping distances. This compromises vehicle control and safety, especially when the truck is fully loaded.

The genuine Shacman hose is not made from ordinary rubber. It uses specialized compounds like Nitrile Butadiene Rubber (NBR) or Ethylene Propylene Diene Monomer (EPDM).

NBR offers excellent resistance to oils and fuels, which is crucial in an engine bay environment. EPDM provides superior resistance to weathering, ozone, and steam.

The hose body is reinforced with one or more layers of high-strength polyester or aramid cord. This reinforcement contains the internal pressure and prevents swelling or bursting.

The end fittings are permanently attached via a high-pressure crimping or molding process. This creates a monolithic unit that is far more reliable than push-on hoses with separate clamps.

Under-hood temperatures can be extreme. The hose material must remain flexible in sub-zero cold and resist softening or degrading under high heat.

Exposure to ozone from electrical components and UV radiation from sunlight can cause surface cracking in inferior rubbers. The genuine hose is formulated to resist this.

Road chemicals, salt, and grime are also constant threats. The hose’s outer cover is designed to be abrasion-resistant and easy to clean during routine inspections.

Each Shacman truck model has a unique pneumatic system layout. The hose BY61560110117 is engineered with a specific length, bend radius, and fitting orientation.

Using the correct OEM part ensures the hose routes cleanly without sharp kinks or tension. This prevents premature fatigue and failure at the fitting connections.

The inner diameter is precisely sized to provide adequate airflow without unnecessary restriction. A hose that is too small can create a pressure drop, affecting performance.

The thread type and sealing method (e.g., tapered threads with sealant, O-ring boss) of the end fittings are matched to the receiving ports on Shacman components.

Even with the correct hose, improper installation can cause failure. The hose must be secured with appropriate clamps or brackets to prevent excessive movement.

Chafing against chassis components, hot surfaces, or sharp edges must be avoided. The OEM hose is often supplied with protective sleeves or specific routing instructions.

Following the factory routing path is essential. It ensures adequate clearance from exhaust manifolds, moving parts, and areas prone to debris impact.

Before installation, always depressurize the entire air system by releasing air from the tanks. This is a critical safety step to prevent accidental hose whip or component activation.

Clean the mating threads on both the hose fitting and the component port. Apply the recommended thread sealant (if required) sparingly to avoid blocking internal air passages.

Tighten fittings using the correct tools, following the specified torque value if available. Over-tightening can damage threads or crack fittings, while under-tightening causes leaks.

After installation, perform a thorough leak test by building system pressure and applying a soapy water solution to all connections. Bubbles indicate a leak that must be addressed.

Inspect all air hoses during every preventive maintenance interval. Look for signs of cracking, blistering, abrasion, oil swelling, or hard, inflexible spots.

Check fittings for corrosion and ensure they are tight. Listen for audible hissing sounds when the system is pressurized, which is a clear indicator of a leak.

Pay special attention to areas where the hose flexes or is exposed to heat. These are common failure points and should be monitored more closely.

Audible Air Leaks: A hissing or whistling sound from the engine bay or undercarriage is the most direct symptom. The sound’s location often helps pinpoint the faulty hose.

Slow Pressure Recovery: If the air pressure gauges take an unusually long time to reach the cut-out pressure after the compressor engages, a significant leak may be present.

Frequent Compressor Cycling: The air compressor cutting in more often than usual to maintain system pressure is a strong indicator of a leak somewhere in the system.

Reduced System Performance: Sluggish operation of air-powered accessories, such as a slow cab tilt or weak air suspension adjustment, points to inadequate air supply.

Visible Damage: Cuts, deep abrasions, bulges, or cracks on the hose cover. A bulge often indicates a breach in the internal reinforcement layer.

Oil Soaking: Excessive oil on the hose surface can soften certain rubber types, leading to swelling and reduced strength. This may indicate a leak from an adjacent component.

Hardened or Brittle Texture: A hose that has lost its flexibility and feels hard or crumbly to the touch has degraded and is at high risk of cracking open.

Universal air hoses may seem like a cost-effective solution, but they pose several risks. Their material quality is often inferior, leading to a shorter service life.

The end fittings on universal hoses may not match the exact thread pitch, depth, or sealing surface of Shacman components, resulting in difficult installation or persistent leaks.

Their length may not be correct, requiring cutting or stretching, which can compromise the hose integrity or create improper routing that leads to kinking.

The genuine BY61560110117 is a direct, plug-and-play replacement. It guarantees the same performance, durability, and safety factor as the original factory-installed part.

The cost of a system failure due to a burst hose far exceeds the price difference for a genuine part. This includes tow trucks, repairs, and lost revenue from downtime.

A failed brake system hose is a direct safety hazard that can lead to accidents, liability, and damage to cargo and property. There is no room for compromise on brake components.

Using genuine parts supports the vehicle’s warranty status and maintains the integrity of the certified safety systems, which is important for fleet compliance and resale value.

Air brake systems are heavily regulated for commercial vehicle safety. Every component, including hoses, must meet specific performance and durability standards.

The genuine Shacman hose BY61560110117 is manufactured to comply with relevant industry standards (such as SAE, ISO, or GB standards) for pneumatic hose assemblies.

Using non-compliant parts can lead to a vehicle failing a safety inspection (e.g., DOT inspection), resulting in fines and the vehicle being placed out of service.

For fleet operators, standardizing on genuine OEM hoses simplifies maintenance records and demonstrates a commitment to safety and regulatory adherence.

A reliable air hose prevents moisture and contaminants from entering the system at connection points, protecting sensitive valves and actuators from internal corrosion.

It ensures consistent pressure is delivered to all subsystems, allowing them to operate as designed by the engineers, which maximizes efficiency and component lifespan.

A well-maintained air system with quality components like the BY61560110117 hose contributes to lower overall operating costs and higher vehicle availability.

The Shacman Air Connection Rubber Hose BY61560110117 is a fundamental component that ensures the reliable and safe operation of your truck’s pneumatic systems.

Choosing the genuine OEM part is a direct investment in vehicle uptime, safety, and long-term cost-effectiveness. It guarantees perfect fitment and proven durability.

Do not compromise the integrity of your air brake and pneumatic systems. Always specify part number BY61560110117 for hose replacements to ensure optimal performance.

Combine this genuine component with professional installation and a proactive inspection regimen. This approach will ensure your Shacman truck’s air systems remain leak-free, responsive, and dependable for countless miles on the road.