Clamp

Хомут

Abrazadera

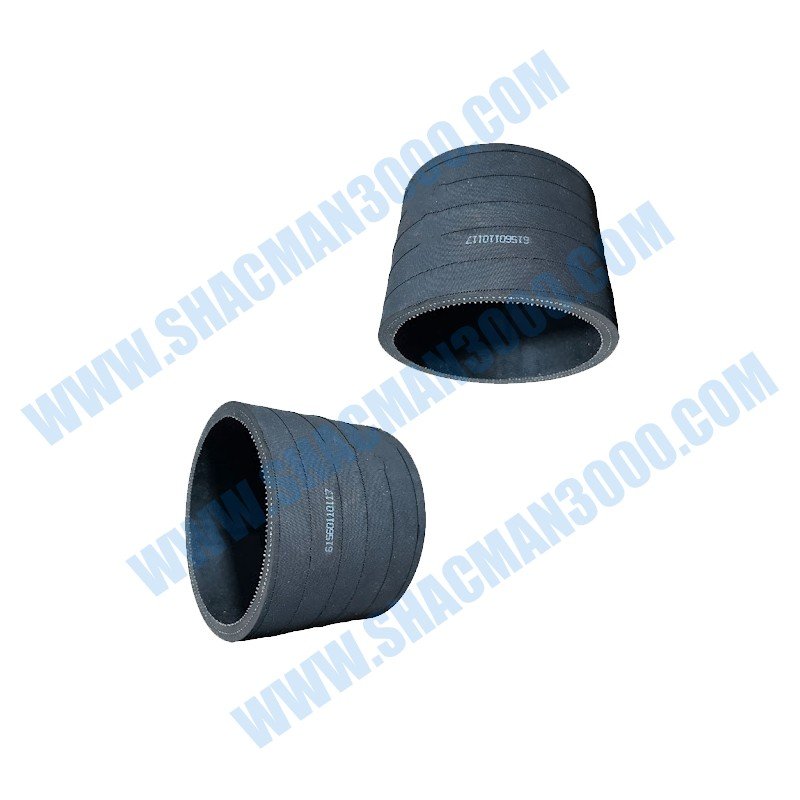

The Shacman Clamp BY612600113794 is a precision-engineered fastening component essential for securing hoses, lines, and cables throughout your truck. This genuine OEM part, identified by the exact number BY612600113794, provides a reliable, vibration-proof hold that prevents leaks, abrasion, and component failure. In the demanding environment of a heavy-duty truck, a failed clamp can lead to costly coolant loss, air pressure leaks, or electrical issues. Using the correct Shacman clamp ensures the specified clamping force and material compatibility, safeguarding the integrity of vital systems like fuel, air, cooling, and hydraulics.

Manufactured from high-grade materials and designed for specific applications, this clamp offers superior corrosion resistance and long-term durability compared to generic alternatives. Its exact dimensions and strength are calibrated to Shacman’s engineering standards, guaranteeing a perfect fit and reliable performance under constant stress and temperature fluctuations.

| Parameter | Specification / Value |

|---|---|

| OEM Part Number | BY612600113794 |

| Product Name | Clamp |

| Brand | Shacman |

| Primary Material | Stainless Steel or Zinc-Plated Steel |

| Clamp Type | Constant-Tension / Spring Clamp or Screw/Worm-Drive Clamp |

| Diameter Range | Model-Specific (e.g., 30-50mm) |

| Width | Standard (e.g., 9mm) |

| Application | Securing Coolant, Air, Fuel, or Hydraulic Hoses |

| Temperature Resistance | -40°C to +120°C (Dependent on Material) |

| Key Feature | Vibration-Resistant, Consistent Sealing Pressure |

Clamps are the unsung heroes of truck reliability. Their function is simple but vital: to create and maintain a leak-proof seal between a hose and its mating nipple or pipe.

A high-quality clamp like BY612600113794 applies even, radial pressure around the entire hose circumference. This prevents the hose from slipping off under pressure or vibration.

In cooling systems, a failed clamp can cause rapid coolant loss leading to engine overheating. In air brake systems, a leaking clamp can result in dangerous pressure loss.

Beyond sealing, clamps also protect hoses from chafing against brackets or other components by holding them securely in their designated routing path.

A weak or corroded clamp can lose tension over time. This allows microscopic movement of the hose, which eventually leads to fluid or air seepage.

A sudden clamp breakage can cause a hose to detach completely. This results in an immediate and total loss of system fluid or pressure, often stranding the vehicle.

Using an incorrect clamp that is too large or applies uneven pressure can deform the hose, creating a weak spot that will fail prematurely.

Shacman clamps are designed for heavy-duty applications. They are typically made from stainless steel for excellent corrosion resistance or from plated steel for cost-effective durability.

Constant-tension (spring) clamps are often used in cooling systems. They automatically adjust to compensate for hose swelling and shrinkage due to temperature changes.

Worm-drive (screw) clamps provide very high and adjustable clamping force. They are common on air, fuel, and hydraulic lines where a robust, permanent seal is required.

The band material is precisely formed to have smooth edges. This prevents it from cutting into the hose material, which is a common failure point with cheap, sharp-edged clamps.

Truck engines generate significant vibration. The clamp’s design, including its locking mechanism (e.g., rolled threads on a worm-drive), must resist self-loosening.

The genuine BY612600113794 is tested to maintain its clamping force through millions of vibration cycles. This ensures the seal remains intact for the long haul.

Materials are chosen to withstand under-hood temperatures, exposure to road salts, oils, and chemicals without degrading or losing tensile strength.

Not all clamps are interchangeable. Part number BY612600113794 is specified for particular hose diameters and system pressures on Shacman trucks.

Using the correct clamp ensures the hose is compressed enough to seal but not so much that the hose reinforcement is damaged, which can cause a future blowout.

The clamp may be designed for a specific location with space constraints. An incorrectly sized clamp can interfere with adjacent components or fail to fit in the allocated space.

Always refer to the OEM number when replacing a clamp. This guarantees you get a part with the exact mechanical properties and dimensions intended by Shacman engineers.

Coolant system clamps must resist ethylene glycol and high temperatures. Fuel system clamps must be compatible with diesel and any biodiesel blends.

Air system clamps must seal effectively on rubber or nylon tubing without causing cracking over time. The right material and design are crucial for each medium.

The genuine clamp is validated for its specific application, ensuring long-term compatibility and preventing chemical degradation of either the clamp or the hose.

Proper installation is key to clamp performance. For worm-drive clamps, position the clamp so the tightening screw is accessible for future inspection.

The band should be centered on the hose bead or nipple. Tighten the clamp to the specified torque (if available) or until snug, then give a final quarter-turn.

Avoid over-tightening, which is the most common installation error. It can cut the hose, strip the threads, or distort the clamp, leading to premature failure.

During routine maintenance, inspect clamps for signs of corrosion, cracking, or looseness. Re-torque screw clamps if necessary, especially after the first few heat cycles on a new hose.

Always replace the clamp when replacing a hose. Reusing an old clamp on a new hose is false economy, as the clamp has already undergone stress and may be near fatigue.

Replace any clamp that shows heavy rust, a distorted band, or stripped threads. These are clear indicators that the clamp can no longer perform its function reliably.

If a hose connection is leaking, inspect the clamp first. Often, simply replacing a tired clamp with a new BY612600113794 can solve the leak without needing a new hose.

Visible Leaks: The most obvious sign. Dampness or drips at the hose connection point often trace back to an inadequately tightened or corroded clamp.

Hose Movement: If you can twist or slide a hose on its nipple by hand, the clamp is not tight enough. This will inevitably lead to a leak.

Visible Damage: Severe rust, a broken band, or a missing screw are clear visual cues that the clamp has failed and requires immediate replacement.

System Performance Issues: Overheating (from coolant loss) or low air pressure (from an air leak) can sometimes be traced to a failing clamp elsewhere in the system.

During service, check all accessible clamps. Look for white corrosion deposits (especially on aluminum parts), which indicate electrolytic corrosion.

Feel for wetness around connections. Use a flashlight to inspect clamps in dark areas of the engine bay or underbody.

Listen for hissing sounds from air system connections when the brakes are applied or the suspension adjusts.

Generic clamps often use lower-grade steel that is more prone to rust. Their plating may be thin and non-uniform, offering minimal protection.

The screw threads on cheap worm-drive clamps are often poorly formed and strip easily. The band may have sharp, unfinished edges that damage hoses.

Generic spring clamps may not have the correct spring tension. Too weak, and they leak; too strong, and they can crush the hose or be impossible to install.

The genuine BY612600113794 is manufactured to precise tolerances with quality-controlled materials. It delivers consistent, reliable performance you can trust.

The price difference between a generic and a genuine clamp is minimal. However, the cost of a tow, repair, and downtime from a clamp-induced failure is enormous.

A failed clamp can ruin a perfectly good, expensive hose by cutting into it or allowing it to blow off and be damaged. This doubles the repair cost.

For fleet managers, standardizing on genuine Shacman clamps like BY612600113794 reduces unexpected breakdowns and streamlines parts inventory.

A secure hose connection is a safety issue. A burst coolant hose can spray scalding fluid. A detached air brake hose can cause a sudden loss of braking power.

Using the correct, high-quality clamp is a simple and effective way to mitigate these risks. It is a critical component in a defense-in-depth approach to vehicle safety.

Regular inspection and replacement of clamps should be part of every preventive maintenance schedule. This proactive approach catches problems before they cause failures.

In regulated industries, using OEM-specified parts like the BY612600113794 helps demonstrate due diligence in maintaining a safe and compliant vehicle.

Reliability is built from thousands of small, correct decisions. Specifying the right clamp for every connection is one of those decisions.

A truck free of fluid and air leaks runs more efficiently, is easier to maintain, and presents a more professional image. It reflects care and attention to detail.

Investing in genuine components for even the smallest parts builds a culture of quality that pays dividends in reduced downtime and lower total operating cost.

The Shacman Clamp BY612600113794, while small, is a fundamental component for ensuring the integrity and reliability of your truck’s fluid and air systems.

Choosing the genuine OEM part is a smart, cost-effective investment in preventative maintenance. It guarantees the correct fit, material, and performance for your specific Shacman model.

Do not underestimate the importance of this simple component. Always specify part number BY612600113794 for clamp replacements to secure your systems and protect your investment.

Combine this genuine clamp with proper installation techniques and regular system checks. This proactive approach will help keep your Shacman truck running cleanly, efficiently, and reliably for hundreds of thousands of miles.