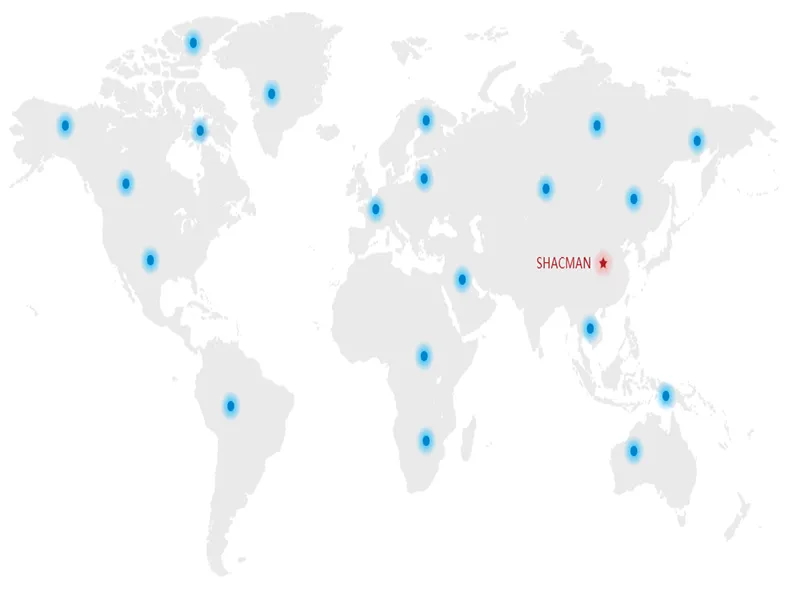

The Architecture of the SHACMAN Parts Global Supply Network

The SHACMAN Parts Global Supply Network is a meticulously engineered ecosystem. It is designed for resilience and speed. This network ensures part availability is never a bottleneck for operations. It spans every continent where SHACMAN trucks work.

At its core lies a two-tier inventory strategy. Global hubs act as central mega-warehouses. Regional centers are strategically placed near key markets. This structure minimizes the distance between parts and the machines needing them.

By 2025, SHACMAN has established over 40 overseas offices. These are not just administrative units. They are active nodes in the supply chain. They manage a web of more than 240 dedicated parts distribution channels.

A modern logistics and distribution center, similar to SHACMAN’s global hubs.

Comprehensive Service Point Coverage

With more than 550 overseas service outlets, the network’s density is impressive. This is crucial in high-demand regions. Africa, Southeast Asia, Central Asia, and the Middle East are primary focus areas.

Each service outlet is a guaranteed access point. It provides genuine SHACMAN parts and certified technical support. This dual function reduces vehicle downtime significantly. It turns a simple parts delivery into a complete service solution.

The expansion of this physical network is continuous. It follows SHACMAN’s vehicle sales and major infrastructure projects. This proactive growth ensures the supply network always stays ahead of demand.

Unmatched Speed: The 48/72-Hour Delivery Promise

Speed defines the modern SHACMAN Parts Global Supply Network. The promise is clear. In key markets like Algeria and Russia, 90% of common wear-and-tear parts arrive within 48 hours. This is a game-changer for fleet operators.

For special vehicle parts or emergency requests, the commitment extends to 72 hours globally. This emergency response protocol is activated for critical breakdowns. It involves prioritized picking, packing, and air freight logistics.

This speed is not accidental. It is the result of localized stockpiling of high-demand items. Fast-moving parts are pre-positioned in regional centers. This eliminates long international shipping for most routine orders.

Express logistics ensure timely delivery within the SHACMAN Parts Global Supply Network.

Project-Based Pre-Stocking Strategy

For major infrastructure projects, SHACMAN deploys a tailored approach. Take the Algeria East-West Highway project as a model. Dedicated service teams were stationed on-site.

Millions of dollars worth of parts were pre-positioned in dedicated local warehouses. This created a “zero-delay” response buffer. Project managers could operate with confidence, knowing part availability was guaranteed locally.

This strategy transforms the SHACMAN Parts Global Supply Network from reactive to proactive. It anticipates need based on project scale and vehicle deployment. It is a premium service layer for large-scale clients.

Optimized International Logistics

Approximately 60% of exported parts in 2025 use a multi-port strategy. Primary ports like Shanghai and Qingdao work in coordination. This disperses shipping volume and reduces port congestion delays.

Logistics partners are selected based on reliability and regional reach. Real-time tracking is standard for all international shipments. This visibility allows for better planning at the receiving service center.

The constant optimization of shipping routes and customs processes is key. It ensures the “global” in the SHACMAN Parts Global Supply Network translates to efficiency, not just distance.

Digital Backbone & Lifecycle Support

The physical network is empowered by a digital nervous system. The “SHACMAN Cloud Service” platform is central to this. It enables Over-The-Air (OTA) vehicle diagnostics and health monitoring.

This technology can predict potential failures before they cause breakdowns. The system can then automatically trigger a parts request. It dispatches the needed part from the nearest stockist to the expected service location.

This predictive capability drastically reduces unplanned downtime. It moves maintenance from a schedule-based model to a condition-based model. The SHACMAN Parts Global Supply Network thus feeds this intelligent system with physical components.

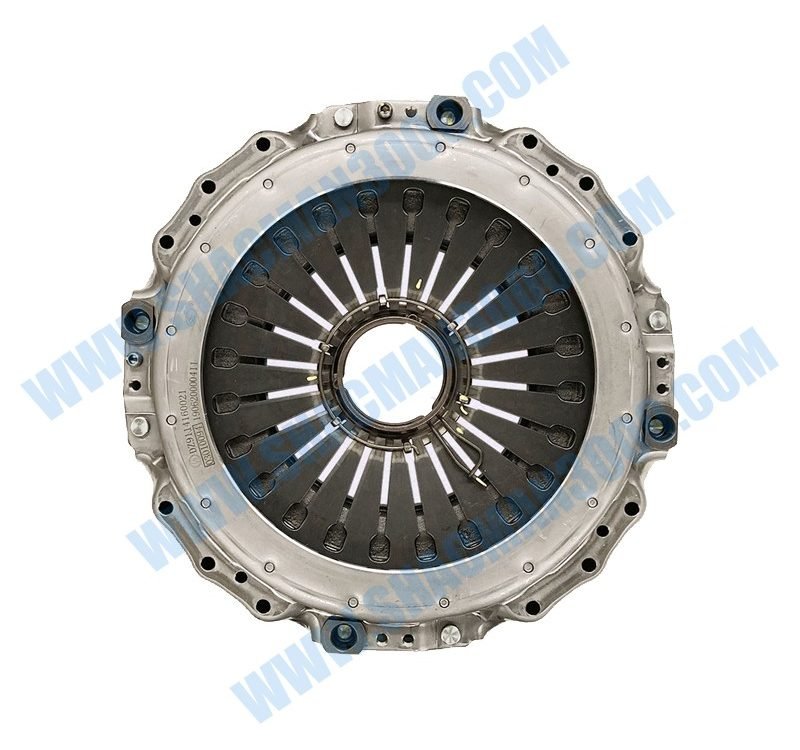

Comprehensive Parts Range & Warranty

The network supports the entire SHACMAN model range. This includes the X6000, X5000, and X3000 series. Every component, from engine parts to cabin fittings, is available.

Genuine SHACMAN parts ensure optimal performance and longevity. They come with the backing of SHACMAN’s quality assurance. For 2025 models, this support includes a strong 36-month or 300,000-kilometer warranty.

This warranty is honored globally through the unified SHACMAN Parts Global Supply Network. Wherever the truck operates, warranty service and parts are accessible. This global consistency is a major client benefit.

Digital platforms enable seamless parts ordering and tracking.

The Online Parts Portal

Clients have 24/7 access to the official SHACMAN parts portal. This platform allows for intuitive parts identification using VIN or model number. Real-time inventory checks can be performed against local warehouses.

Orders placed through the portal integrate directly into the supply network’s fulfillment system. They benefit from the same priority and tracking as orders placed through service centers. This self-service option adds tremendous flexibility for clients.

The portal is a transparent window into the SHACMAN Parts Global Supply Network. It builds trust by showing availability and providing delivery estimates upfront. It is a key tool for fleet managers planning maintenance.

Strategic Advantages for Global Clients

Operating a global fleet requires a global support system. The SHACMAN Parts Global Supply Network provides exactly that. It offers a single, reliable standard of support across different countries.

This eliminates the risk and complexity of sourcing parts locally from various suppliers. Clients deal with one system, one quality standard, and one accountability chain. This simplifies logistics and procurement on the client’s side.

The network’s rapid delivery capability directly impacts the client’s bottom line. Reduced vehicle downtime means higher asset utilization and profitability. Reliability becomes a competitive advantage for the client’s business.

Risk Mitigation

Localized stock buffers against global supply chain disruptions and port delays, ensuring continuous operation.

Predictable Operations

Known delivery timelines allow for accurate maintenance scheduling and project planning, eliminating surprises.

Total Lifecycle Partnership

SHACMAN supports clients not just at point of sale, but throughout the entire operational life of the vehicle.

Future-Proofing the Network: Continuous Evolution

The SHACMAN Parts Global Supply Network is not static. It is designed to evolve with market demands and technological advancements. Investment in automation within warehouses is ongoing.

Data analytics play an increasingly large role. Sales data, failure rates, and regional usage patterns are analyzed. This data informs future inventory planning, making stock levels even more precise and responsive.

Exploration into additive manufacturing (3D printing) for certain low-volume, high-complexity parts is on the horizon. This could further revolutionize availability in remote locations, making the network even more resilient.

The goal is constant improvement in key metrics: time-to-delivery, first-time fill rate, and overall client satisfaction. The SHACMAN Parts Global Supply Network is a core brand promise, and its enhancement is a perpetual priority.

Sustainability in the Supply Chain

Efficiency also means environmental responsibility. The network optimization reduces wasted journeys and unnecessary air freight. Consolidated shipping leads to a lower carbon footprint per part delivered.

Packaging materials are being reviewed for sustainable alternatives. The long-term vision is a SHACMAN Parts Global Supply Network that is not only fast and reliable but also aligns with global sustainability goals.

This holistic approach ensures that clients who prioritize green operations can rely on SHACMAN. The network’s efficiency contributes to the client’s own environmental, social, and governance (ESG) targets.

Conclusion: A Network Built for Dependability

The SHACMAN Parts Global Supply Network represents a paradigm shift in commercial vehicle support. It transcends traditional parts distribution by combining vast physical reach with digital intelligence and an unwavering commitment to speed. By guaranteeing rapid availability through localized stock and streamlined logistics, SHACMAN doesn’t just sell trucks—it sells operational continuity and peace of mind. For any business operating in today’s fast-paced, downtime-sensitive environment, this network is not just an added benefit; it is a critical strategic asset that safeguards productivity and profitability on a global scale. The SHACMAN Parts Global Supply Network is the reliable backbone for fleets around the world, ensuring they keep moving, no matter where the road leads.