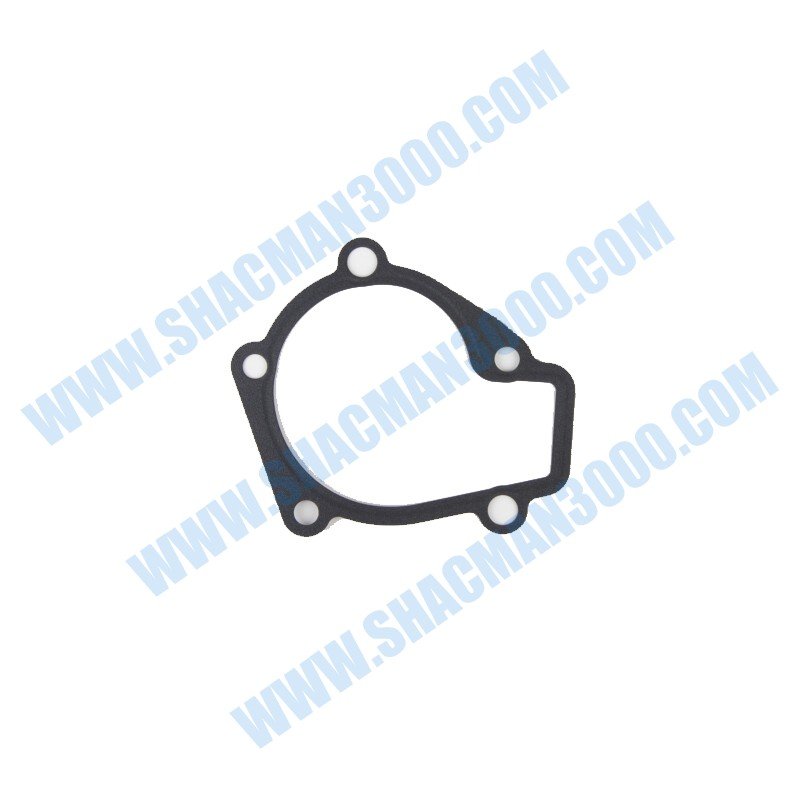

The Shacman Water Pump Gasket, identified by the genuine OEM part number BY1001134455, is a critical sealing component essential for the leak-free operation of your truck’s engine cooling system. This precision-engineered gasket is installed between the water pump and the engine block, creating a durable, high-pressure seal that prevents coolant leakage. The proper function of gasket BY1001134455 is non-negotiable; even a minor leak can lead to coolant loss, resulting in engine overheating, severe thermal damage, and costly unplanned downtime. This OEM part is specifically designed for a perfect fit on Shacman heavy-duty truck models.

Manufactured from advanced composite materials resistant to ethylene glycol coolants, heat, and pressure cycling, this gasket ensures long-term reliability. Using the authentic Shacman BY1001134455 gasket during water pump replacement or cooling system overhaul is a fundamental best practice. It guarantees the integrity of one of the engine’s most vital systems, protecting your investment in Shacman F3000, X3000, M3000, and other series trucks by maintaining proper coolant circulation and engine operating temperature.

The Water Pump Gasket BY1001134455 serves one indispensable purpose: to create a perfect, high-integrity seal at the mating surface between the engine block (or timing cover) and the water pump housing. This interface is under constant pressure from the circulating coolant pumped throughout the engine. The gasket must seal this pressure while withstanding significant temperature fluctuations from ambient cold starts to normal operating heat.

Without this seal, coolant would escape, leading to a drop in system pressure and coolant volume. This compromises the cooling system’s efficiency, causing the engine to overheat. Overheating is a primary cause of catastrophic engine failure, including warped heads, blown head gaskets, and seized pistons. Thus, this small, inexpensive part is a guardian of the entire engine’s health.

The gasket must compensate for microscopic imperfections on the machined metal surfaces of the pump and block. It fills these tiny voids to prevent even minute seepage. It also must maintain its seal despite the different thermal expansion rates of the aluminum pump housing and the cast iron engine block, which can cause slight shifting and stress at the mating surface.

The Shacman BY1001134455 gasket is engineered from high-quality, multi-layer composite materials. Common constructions include a solid steel or graphite core layered with rubberized coating or a high-temperature fiber material impregnated with a sealing compound. These materials are selected for their resilience, compressibility, and resistance to degradation.

Key material properties include excellent resistance to automotive coolants (ethylene/propylene glycol), corrosion inhibitors, and engine oils. They must remain stable across a wide temperature range, from sub-zero cold to over 120°C (250°F), without becoming brittle or melting. The gasket is precisely die-cut to match the water pump’s bolt holes, coolant passages, and outer perimeter exactly.

The OEM gasket’s design is not generic. The placement and size of coolant port holes, bolt holes, and the outer sealing bead are specific to the Shacman engine model. This ensures coolant flows correctly and at the proper rate between the pump and engine. An ill-fitting aftermarket gasket can block or restrict flow, leading to localized hot spots and cooling inefficiency, even if it doesn’t leak immediately.

Correct installation is as critical as the gasket quality. The mating surfaces on both the engine block and the water pump must be meticulously cleaned of all old gasket material, sealant, rust, or debris. This is best done with a plastic scraper and a chemical gasket remover, avoiding abrasive discs that can gouge the soft aluminum of the pump.

The new BY1001134455 gasket should be placed dry, unless the manufacturer specifically instructs the use of a sealant. Many modern composite gaskets are designed with adhesive coatings and require no additional sealant, which can actually cause misalignment or uneven sealing. Bolts must be tightened in the correct sequence and to the specified torque value, often in multiple stages, to ensure even compression.

A poorly installed gasket will fail prematurely. Uneven bolt torque can cause the gasket to compress more in some areas than others, creating leak paths. Dirt or old gasket material left on the surface creates bumps that prevent a flat seal. Over-tightening can crush and extrude the gasket material, weakening the seal or cracking the water pump housing.

A leaking water pump gasket has clear symptoms. The most obvious is visual evidence of coolant seepage or drips originating from the water pump mating area. You may see a crusty, white, red, or green residue (from dried coolant) around the pump’s edge. The coolant level in the reservoir will drop over time without another visible leak.

In some cases, a leak may allow air to be sucked into the cooling system when the engine cools down. This can lead to overheating issues, gurgling sounds from the dashboard heater core, or an erratic engine temperature gauge reading. Any sign of moisture or coolant around the pump mandates immediate inspection and repair.

The water pump gasket is a wear item replaced preventively. It should always be replaced with a new pump installation. Many professional technicians also recommend replacing it during major timing belt or engine services that require pump removal, even if the pump itself is still functional. This “while you’re in there” practice prevents future leaks.

The OEM part BY1001134455 is designed for specific Shacman heavy-duty truck engines used in series like the F3000, X3000, and M3000. It matches the water pump used on particular engine models (e.g., Weichai WP10, WP12). Using the correct gasket is vital, as water pump designs vary significantly between engine families.

Always verify the part number against your truck’s VIN or engine model. Installing an incorrect gasket can lead to immediate leakage, blocked coolant passages, or misaligned bolt holes, which can cause damage when bolts are tightened. The genuine gasket ensures all ports align perfectly for unobstructed coolant flow.

Choosing the genuine BY1001134455 over a generic gasket provides guaranteed quality and fit. OEM gaskets use material formulations tested and approved by Shacman engineers for long-term compatibility with their engines and coolants. The cutting dies are exact, ensuring no blockage or misalignment of critical coolant passages.

Aftermarket gaskets may use cheaper composites that harden and crack prematurely or lack the precise adhesive application for proper hold during assembly. The cost of a coolant leak—in lost fluid, repair labor, and potential engine damage—far outweighs the minimal price difference of opting for the genuine OEM part.

For fleet managers, reliable sealing components are key to predictable maintenance. A failed gasket causes unscheduled downtime, tow bills, and urgent repair costs. Using genuine gaskets like the BY1001134455 as part of a disciplined preventive maintenance program maximizes vehicle availability and reduces the total cost of ownership by avoiding cascade failures.

The Shacman Water Pump Gasket BY1001134455 exemplifies that a component does not need to be large or complex to be critically important. As the foundational seal of the cooling system, its failure jeopardizes the entire engine. Its role in maintaining system pressure, preventing coolant loss, and ensuring efficient heat transfer is indispensable.

Never overlook this part during cooling system service. Always insist on the genuine OEM gasket to ensure a perfect seal from the moment of installation. Pair it with proper installation techniques for a repair that lasts. By securing this small but vital interface with the authentic BY1001134455, you protect your Shacman truck’s engine from the severe risks of overheating and ensure countless miles of reliable, leak-free operation.

For a complete cooling system repair, explore our range of genuine Shacman components, including water pumps, thermostats, hoses, and coolant, all designed to work together seamlessly for optimal performance and durability.