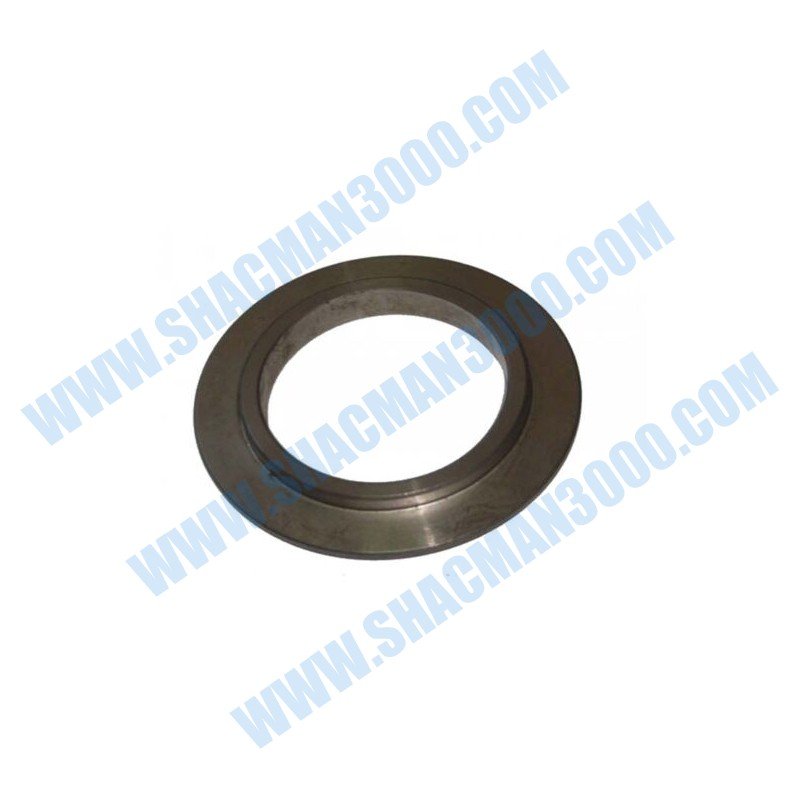

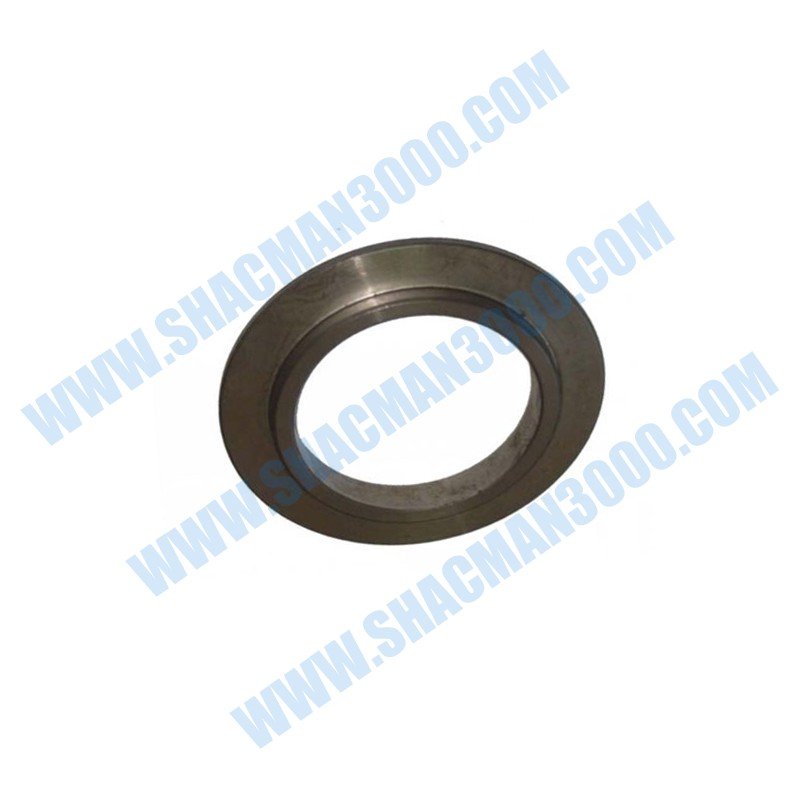

The Shacman Fuller 12Js160T Transmission Output Shaft Washer with OEM number 12JS160T-1707108 is a critical component designed for heavy-duty truck transmissions. This precision-engineered washer ensures optimal performance and longevity of your transmission system.

Manufactured to exact specifications, this transmission output shaft washer provides reliable sealing and proper spacing within the transmission assembly. It plays a vital role in maintaining the correct alignment and reducing friction between moving parts.

The 12JS160T-1707108 washer is crafted from high-quality materials that withstand extreme pressure and temperature conditions. Its durable construction ensures it can handle the rigorous demands of commercial truck operations.

This component is specifically designed for Fuller 12Js160T and 12Js200T transmission systems. It guarantees perfect compatibility and performance when used as a replacement part in Shacman trucks.

Regular maintenance and timely replacement of this washer can prevent transmission failures and extend the life of your vehicle’s drivetrain system. It represents an essential investment in your truck’s reliability.

| Parameter | Value |

|---|---|

| OEM Number | 12JS160T-1707108 |

| Product Name | Fuller 12Js160T, 12Js200T Transmission Output Shaft Washer |

| Brand | Shacman |

| Compatible Models | Fuller 12Js160T, 12Js200T Transmission Systems |

| Material | High-grade Steel Alloy |

| Thickness | Precision-engineered to exact specifications |

| Diameter | Custom fit for transmission output shaft |

| Heat Treatment | Tempered for enhanced durability |

| Surface Finish | Smooth, corrosion-resistant coating |

| Application | Heavy-duty truck transmissions |

The Shacman transmission output shaft washer is engineered with precision to deliver exceptional performance. Its unique design ensures perfect fitment and reliable operation in demanding conditions.

This washer features high tensile strength that withstands extreme pressure and torque loads. The material composition prevents deformation under heavy operational stress.

Advanced manufacturing techniques guarantee consistent thickness and dimensional accuracy. This precision ensures optimal performance in transmission systems.

The corrosion-resistant coating extends the component’s lifespan significantly. It protects against rust and degradation in various environmental conditions.

Thermal stability is another key advantage of this transmission washer. It maintains structural integrity across a wide temperature range.

The washer undergoes rigorous heat treatment processes to enhance its mechanical properties. This treatment increases hardness while maintaining necessary flexibility.

Quality control measures ensure each washer meets strict tolerance standards. This attention to detail guarantees reliable performance in every unit.

Proper installation of this washer ensures smooth transmission operation. It reduces vibration and noise while improving power transfer efficiency.

The design minimizes wear on adjacent components, extending the overall transmission life. This results in reduced maintenance costs over time.

The Fuller 12Js160T transmission output shaft washer is specifically designed for Shacman heavy-duty trucks. It ensures perfect compatibility with Fuller transmission systems.

This component is essential for various commercial vehicle applications. It serves in long-haul transportation, construction, and mining operations.

The washer fits perfectly in both 12Js160T and 12Js200T transmission models. This versatility makes it a valuable spare part for fleet maintenance.

Regular replacement of this washer during transmission overhaul prevents potential failures. It is a crucial preventive maintenance component.

Fleet operators can standardize their inventory with this reliable component. It reduces downtime and maintenance complexity across multiple vehicles.

This transmission washer is compatible with Shacman F2000, F3000 series trucks. It also fits various other heavy-duty commercial vehicles.

The component is designed to work with specific transmission configurations. Always verify compatibility before installation.

Proper installation of the transmission output shaft washer is crucial for optimal performance. Follow manufacturer guidelines for best results.

Begin by ensuring the transmission is properly supported and secure. Clean all mating surfaces thoroughly before installation.

Position the washer correctly according to transmission assembly diagrams. Ensure proper orientation for optimal function.

Use appropriate torque specifications during reassembly. Overtightening can damage the washer and adjacent components.

After installation, conduct proper testing and inspection. Verify there are no leaks or abnormal noises during operation.

Always disconnect the vehicle battery before beginning transmission work. This prevents accidental engagement during service.

Use proper lifting equipment and safety stands when working underneath vehicles. Never rely solely on hydraulic jacks for support.

Shacman maintains strict quality control standards for all transmission components. Each washer undergoes multiple inspections before shipment.

The manufacturing process utilizes advanced metallurgical techniques. This ensures consistent material properties and performance.

Dimensional accuracy is verified using precision measuring instruments. This guarantees perfect fitment in transmission assemblies.

Material certification accompanies each production batch. This provides traceability and quality verification.

Performance testing simulates real-world operating conditions. This validation ensures reliability in demanding applications.

Each washer undergoes hardness testing to verify proper heat treatment. This ensures optimal mechanical properties.

Surface finish inspection guarantees smooth operation and proper sealing. This prevents premature wear and fluid leaks.

Shacman genuine parts guarantee perfect compatibility with your vehicle. They are engineered to original equipment specifications.

Using genuine components ensures optimal performance and longevity. Aftermarket parts may not meet the same quality standards.

Shacman parts come with reliable technical support and documentation. This assistance helps with proper installation and troubleshooting.

The company’s reputation for quality spans decades in the commercial vehicle industry. This experience translates into superior product design.

Genuine parts protect your vehicle warranty and maintain resale value. They demonstrate proper maintenance and care for your investment.

Investing in genuine Shacman parts reduces total cost of ownership. They last longer and prevent secondary damage to other components.

Proper maintenance with quality parts maximizes vehicle uptime and productivity. This is crucial for commercial operations.

Regular transmission inspection should include checking the output shaft washer. Look for signs of wear or deformation during service intervals.

Replace the washer during any transmission overhaul or repair. This preventive measure avoids future failures and downtime.

Monitor transmission fluid condition and levels regularly. Contaminated fluid can accelerate washer and component wear.

Follow recommended service intervals specified in vehicle manuals. Adherence to maintenance schedules extends component life.

Keep records of all transmission maintenance and replacements. This documentation helps predict future service needs.

Regular fluid analysis can detect early signs of transmission problems. This allows proactive component replacement.

Visual inspection during routine maintenance can identify potential issues. Address minor concerns before they become major repairs.

What is the OEM number for this transmission washer? The OEM number is 12JS160T-1707108.

Which transmission models does this washer fit? It is designed for Fuller 12Js160T and 12Js200T transmission systems.

How often should this washer be replaced? Replace during transmission overhaul or if wear is detected during inspection.

What material is the washer made from? It is manufactured from high-grade steel alloy with special heat treatment.

Is professional installation required? While experienced mechanics can install it, professional installation is recommended.

For technical specifications or installation guidance, consult your service manual. Shacman authorized service centers can provide expert assistance.

Always verify part compatibility before purchase. Cross-reference OEM numbers to ensure correct selection for your specific transmission.

The Shacman Fuller 12Js160T Transmission Output Shaft Washer (12JS160T-1707108) represents the pinnacle of transmission component engineering. Its precision manufacturing and durable construction ensure reliable performance in the most demanding operating conditions.

By choosing genuine Shacman parts, you invest in quality, reliability, and peace of mind. This transmission washer delivers the performance and longevity that professional truck operators depend on for their business success.