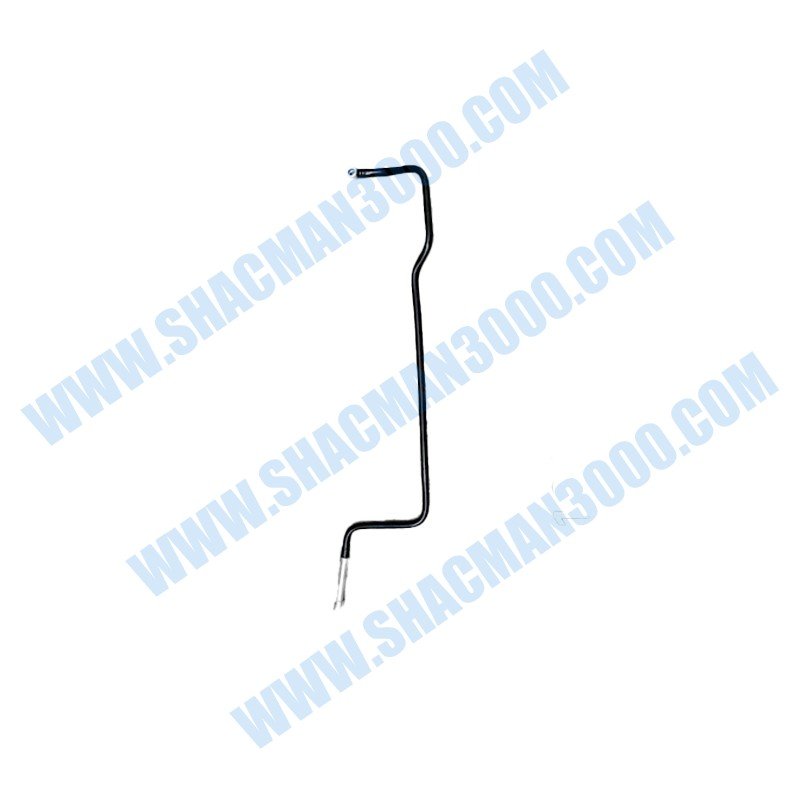

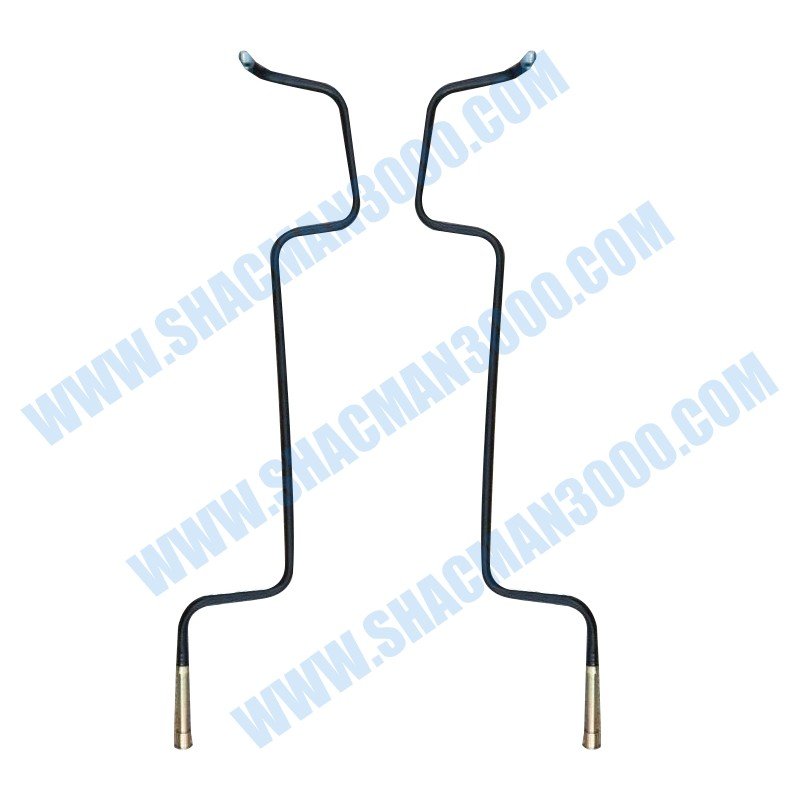

The BY1002029761 is the genuine Shacman Fuel Inlet Pipe Assembly, a crucial component in your truck’s low-pressure fuel supply system. This assembly forms a sealed pathway, delivering diesel fuel from the tank or filter to the high-pressure fuel injection pump. Engineered for durability and leak-free performance, the correct OEM part ensures optimal engine function. A compromised inlet pipe can introduce air into the fuel system or cause leaks, leading to power loss, hard starting, and potential engine damage.

Constructed from high-quality materials resistant to diesel fuel and engine bay temperatures, this assembly guarantees a perfect fit and reliable sealing with its integrated gaskets and connection fittings. Choosing the authentic Shacman BY1002029761 assembly protects your investment by maintaining system integrity, preventing downtime, and ensuring your engine receives a consistent, uninterrupted fuel supply for maximum efficiency and power.

| Parameter | Specification | Details |

|---|---|---|

| OEM Part Number | BY1002029761 | Genuine Shacman Identification Code |

| Product Name | Fuel Inlet Pipe Assembly | Complete assembly with fittings |

| Brand | Shacman | Original Equipment Manufacturer |

| Primary Material | Steel Tube / Reinforced Rubber Hose | Corrosion and fuel resistant |

| Connection Type | BANJO Fitting / Flare Fitting | Ensures secure, high-pressure seal |

| Included Components | Pipe, Banjo Bolts, Washers, Seals | Complete kit for installation |

| Operating Pressure | Low-Pressure Fuel System | Pre-injection pump supply line |

| Compatibility | Shacman Truck Models | Check model-specific application |

SEO Description:

Genuine Shacman Fuel Inlet Pipe Assembly BY1002029761. OEM fuel supply line for reliable, leak-free performance. Ensures optimal fuel delivery to injection pump.

The Fuel Inlet Pipe Assembly BY1002029761 is a critical link in the low-pressure fuel supply circuit. Its primary role is to transport filtered diesel fuel from the fuel filter/water separator assembly to the inlet port of the high-pressure fuel injection pump. It operates under suction from the transfer pump within the injection pump.

This assembly must maintain a perfect seal. Any air ingress through a faulty connection or crack creates “aeration,” where air bubbles mix with the fuel. Aerated fuel reduces lubrication and cooling within the pump, potentially causing catastrophic failure. The OEM assembly is precision-made to prevent this.

A failing inlet pipe can cause severe issues: 1) Hard Starting & Stalling: Air in the system disrupts fuel flow. 2) Loss of Power: Engine fails to receive full fuel supply. 3) Fuel Leaks: Create fire hazards and environmental issues. 4) Pump Damage: Air and debris lead to wear and pump seizure.

Precision OEM Fit: The BY1002029761 is engineered to Shacman’s exact specifications. It matches the original routing, length, and bend angles, ensuring easy installation without stress on the fittings, which is crucial for long-term seal integrity.

Integrated Sealing Solution: This assembly comes as a complete kit with all necessary new sealing washers (copper or aluminum crush washers), O-rings, and banjo bolts. Using new seals is mandatory for a leak-free connection and is far more reliable than reusing old, flattened seals.

Durable Construction: Made from materials specifically chosen for fuel contact and engine bay conditions. The pipe resizes vibration, heat cycling, and exposure to diesel, oils, and underhood chemicals, preventing premature cracking or degradation.

Maintains Fuel System Integrity: By providing a sealed, high-quality pathway, this assembly protects the entire fuel system. It prevents air leaks that cause performance problems and fuel leaks that are wasteful and dangerous, ensuring safe and reliable operation.

Safety First: Before starting, relieve any residual fuel system pressure. Work in a well-ventilated area with no ignition sources. Have absorbent pads ready for minor spills. Always disconnect the battery for safety.

Cleanliness is Critical: Thoroughly clean the area around the filter head and injection pump inlet ports before disassembly. Prevent dirt from entering the open fuel lines, as contamination can damage the injection pump and injectors.

Proper Torque Procedure: When installing banjo bolts, always use new sealing washers on both sides of the banjo fitting. Tighten the bolt to the manufacturer’s specified torque value using a torque wrench. Overtightening can strip threads or crack fittings; undertightening guarantees a leak.

System Priming & Leak Check: After installation, prime the fuel system according to the service manual to remove air. Start the engine and carefully inspect all connections on the new BY1002029761 assembly for any sign of weeping or dripping fuel. Address any leak immediately.

Replace the Fuel Inlet Pipe Assembly during any major fuel system service, such as injection pump or filter housing replacement. Immediate replacement is required if you find visible cracks, abrasions, wet fuel stains, or if the engine exhibits symptoms of air ingestion. Do not attempt temporary repairs on high-pressure fuel lines.

The BY1002029761 assembly likely uses banjo fittings. A banjo fitting is a hollow bolt that allows fuel to flow through its side ports, connecting a pipe to a flat mounting surface. The seal is created by two crush washers—one on each side of the pipe’s banjo eyelet.

These washers are single-use. When the banjo bolt is torqued, the washers deform (“crush”) to fill microscopic imperfections, creating a metal-to-metal seal. Reusing old washers will result in a leak. The genuine Shacman kit includes the correct washers for a perfect seal.

The fuel inlet pipe is a safety-critical component. Non-genuine parts may use inferior tubing or substandard sealing materials that fail under heat and vibration. Incorrect dimensions can cause kinks or stress, leading to cracks. A leak here is both a fire risk and an environmental hazard.

The genuine Shacman assembly is tested and validated to perform under all operating conditions. It ensures compatibility, reliability, and safety. For fleet managers, it guarantees consistent quality and reduces the risk of roadside breakdowns caused by fuel system failures. It is the only choice for a guaranteed, long-term repair.

If experiencing fuel delivery problems, inspect the BY1002029761 inlet pipe assembly. Look for visible damage, wetness, or fuel odor. Check all connections for tightness. To test for air ingress, you can temporarily install a clear section of hose to see bubbles. Often, simply replacing the old assembly and all seals with a new genuine unit resolves persistent air-related faults.

Remember that symptoms of a faulty inlet pipe (hard starting, power loss) mimic other issues like a clogged fuel filter or failing lift pump. A systematic diagnosis, starting with a visual inspection of all low-pressure lines and connections, is essential for an accurate repair.

The Shacman Fuel Inlet Pipe Assembly (OEM: BY1002029761) is far more than just a pipe. It is a precision-engineered, sealed conduit that is vital for delivering clean, air-free fuel to your engine’s heart—the injection pump.

Choosing the genuine part for replacement ensures system integrity, prevents dangerous leaks, and safeguards the performance and longevity of your Shacman truck’s entire fuel system. Do not compromise on this critical component.