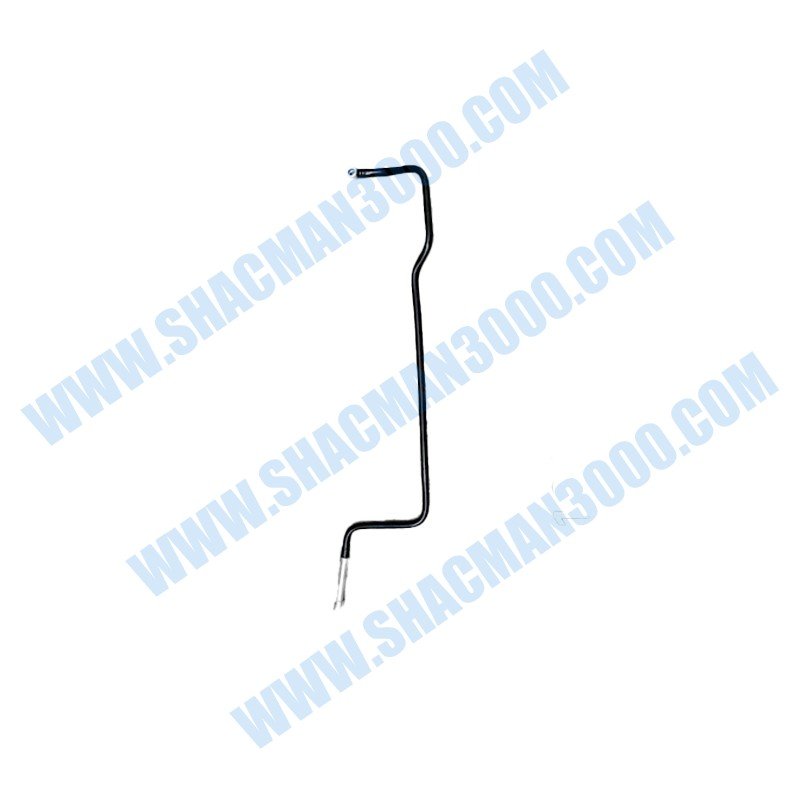

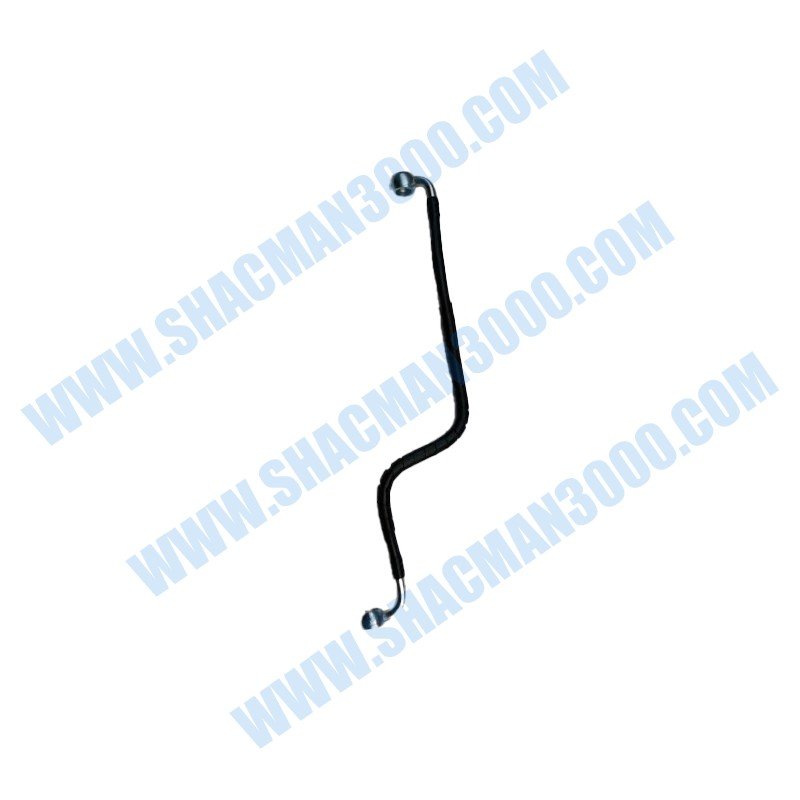

The BY612600083034 is the genuine Shacman Fuel Pipe Assembly, a critical high-pressure line in your truck’s common-rail diesel injection system. This precision-engineered component is responsible for transporting diesel fuel at extreme pressures from the high-pressure pump to the fuel rail or directly to the injectors. Maintaining the integrity of this assembly, identified by its exact OEM number BY612600083034, is paramount for engine safety, performance, and efficiency.

Designed to withstand pressures exceeding 1,800 bar (26,000 psi) and constant vibration, this OEM assembly guarantees a perfect fit and leak-proof performance. A failure in this line is not just a leak; it is a catastrophic loss of system pressure leading to immediate engine shutdown and a severe safety hazard. Choosing the authentic Shacman BY612600083034 assembly is a direct investment in operational reliability and safety.

| Parameter | Specification | Details |

|---|---|---|

| OEM Part Number | BY612600083034 | Official Shacman Identification |

| Product Name | Fuel Pipe Assembly | High-Pressure Fuel Line |

| Brand | Shacman | Original Equipment Manufacturer |

| Material | High-Strength Steel Tubing | Cold-drawn, seamless construction |

| Pressure Rating | Ultra-High Pressure (UHP) | Rated for common-rail system pressures |

| Connection Type | Conical Seat Fittings | Metal-to-metal seal (e.g., DIN / Metric) |

| Function | Deliver Fuel to Rail/Injectors | Critical high-pressure conduit |

| Compatibility | Shacman Common-Rail Engines | Specific to engine model and configuration |

SEO Description:

Genuine Shacman Fuel Pipe Assembly BY612600083034. OEM high-pressure fuel line for common-rail systems. Ensures safe, reliable fuel delivery at extreme pressures for optimal engine performance.

In a modern common-rail diesel engine, fuel is pressurized by a pump to an extremely high level—often between 1,600 and 2,200 bar—and stored in a central “rail.” The Fuel Pipe Assembly BY612600083034 is the critical link that carries this pressurized fuel from the pump to the rail. Its integrity is non-negotiable.

Unlike low-pressure lines, this assembly must contain forces comparable to deep-sea hydrostatic pressures. Any weakness, flaw, or improper installation can result in a sudden, high-velocity fuel spray. This poses an extreme fire risk and causes immediate engine shutdown due to loss of injection pressure.

Critical Design Differences: High-pressure pipes use thick-walled, seamless tubing and conical sealing surfaces. They have no flexible sections and must be routed to avoid stress. A standard low-pressure fuel hose would balloon and burst instantly under common-rail pressures.

Precision-Formed Tubing: The BY612600083034 pipe is not a generic straight tube. It is mandrel-bent to the exact OEM shape, ensuring perfect alignment with mounting brackets and connection points. This prevents stress from misalignment that could lead to fatigue cracks over time.

Advanced Material Integrity: Made from special-grade steel that undergoes specific heat treatment. This provides the ideal balance of high tensile strength to resist bursting and sufficient ductility to handle engine vibration without becoming brittle.

Precision Machined Fittings: The conical seats and union nuts are machined to microscopic tolerances. This guarantees a perfect metal-to-metal seal when torqued, without the need for additional sealing compounds or gaskets, which are unacceptable in high-pressure systems.

Corrosion and Abrasion Resistance: The assembly is often treated or plated to resist corrosion from road salts and moisture. Areas in contact with brackets may have protective sleeves to prevent wear-through from vibration, a common cause of failure in inferior parts.

1. Absolute Cleanliness: Before removing the old pipe, clean the surrounding area meticulously. Before installation, blow out the new BY612600083034 assembly with clean, dry air. Even microscopic particles on a conical seat can cause a leak.

2. Hand-Thread and Final Torque: Never force the fittings. Start all union nuts by hand to ensure threads are not crossed. Then, using a calibrated torque wrench, tighten to the exact specification (e.g., 30 Nm + 90° turn). This controlled preload creates the seal.

3. Secure Routing and Brackets: Ensure the pipe sits correctly in all mounting brackets and clips. These are vibration dampeners and stress relievers. A missing or loose bracket allows the pipe to resonate, leading to metal fatigue and failure.

4. Pressure Testing: After installation, the fuel system must be pressurized and held. Inspect every fitting for any sign of weeping or dripping. A leak test with a fluorescent dye is recommended for absolute certainty before starting the engine.

Attempting to repair a cracked high-pressure fuel line with epoxy, tape, or sleeve is profoundly dangerous and will fail catastrophically. Similarly, using a pipe not specifically designed for this application (wrong material, wall thickness, or fitting geometry) is an extreme safety risk. Replacement with the genuine BY612600083034 is the only safe option.

Failure often gives little warning. A minor leak may manifest as a persistent smell of diesel near the engine, a slight wetness around fittings, or a small drop in fuel pressure causing intermittent power loss or rough idle. A major failure is obvious: a loud hissing noise, a visible spray of fuel, and immediate engine stall.

Regular visual inspection is crucial. Look for signs of:

This is arguably the most safety-critical fluid line on the engine. The genuine Shacman BY612600083034 assembly is not just a pipe; it is a certified component. Its production batch is traceable, its material composition is verified, and it has passed rigorous burst pressure tests (often 2-3 times the operating pressure).

Aftermarket alternatives may claim compatibility but lack this validation. Variations in steel alloy, heat treatment, or dimensional accuracy can lead to premature failure. The risk of engine fire, environmental contamination, and costly downtime far outweighs any minimal upfront cost saving.

High-pressure fuel lines are designed for the life of the engine but are subject to wear. They should be inspected at every major service interval. Replacement is typically prompted by visual defects, leaks, or during major engine overhaul. It is considered best practice to replace all high-pressure fuel lines if one fails, as they experience similar age and stress.

When replacing the BY612600083034, always use new sealing washers if present on banjo-style connections, and ensure all mating surfaces on the pump and rail are clean and undamaged. This is a “fit and forget” component where quality of the part and installation defines long-term safety.

The Shacman Fuel Pipe Assembly (OEM: BY612600083034) is the robust, high-integrity lifeline that delivers the vital energy source to your engine under immense pressure. Its failure is not an option.

Choosing the genuine component ensures you meet the original engineering standard for safety, reliability, and performance. For this critical application, trust only the part engineered and tested by Shacman: the BY612600083034.