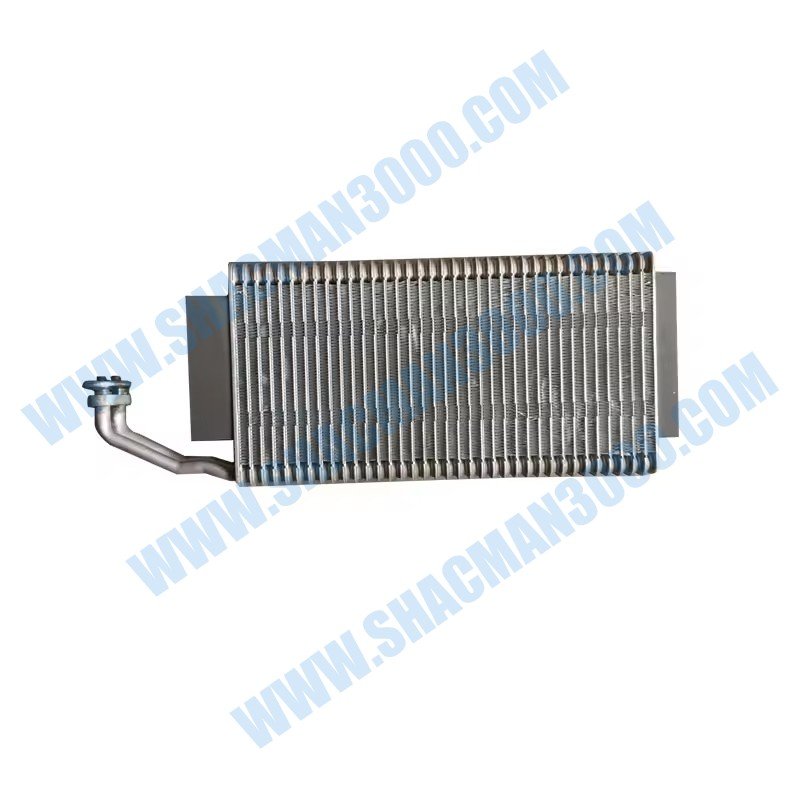

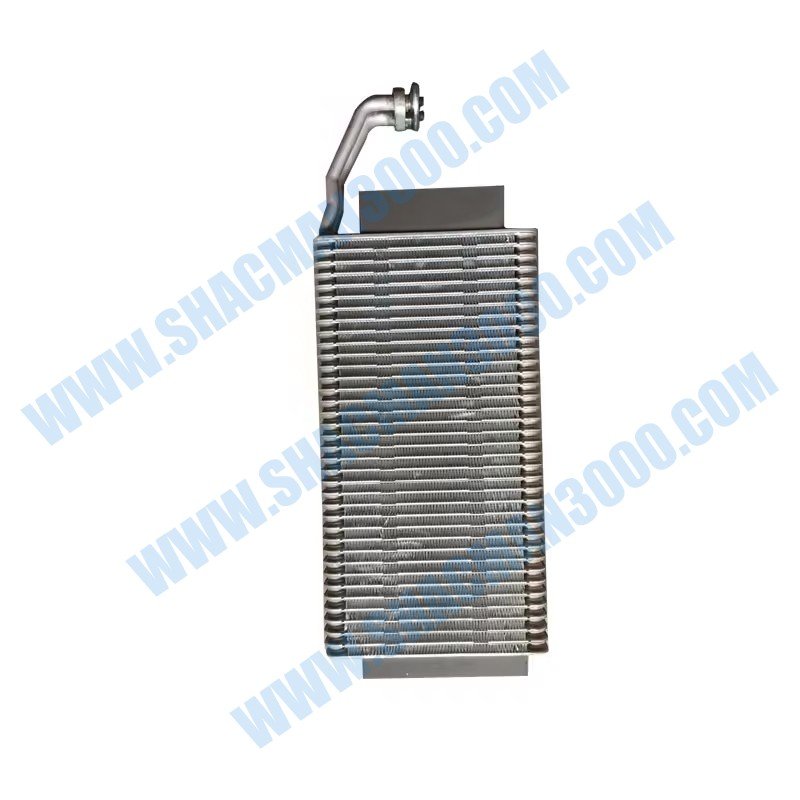

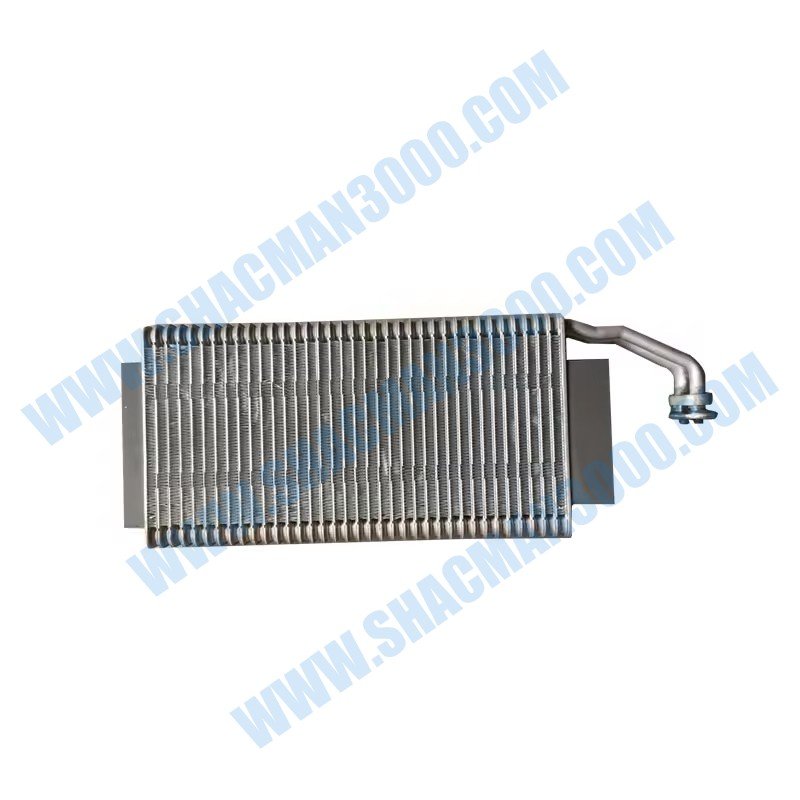

The Shacman Evaporator Assembly, identified by the precise OEM part number DZ13241821111, is the critical heat exchange core of the truck’s air conditioning (A/C) system. Located inside the HVAC (Heating, Ventilation, and Air Conditioning) module within the cabin dashboard, this assembly is responsible for absorbing heat from the incoming air, thereby cooling and dehumidifying it before it is circulated throughout the truck’s interior. The genuine part DZ13241821111 is engineered to deliver maximum cooling efficiency, durability, and reliable performance under the demanding conditions of commercial trucking. Its proper function is essential for maintaining a comfortable and safe cabin environment, reducing driver fatigue, and preventing window fogging during long hauls in varying climates.

Constructed with a network of aluminum or copper tubing and delicate aluminum fins, the evaporator core facilitates the phase change of the refrigerant from a low-pressure liquid to a gas, which absorbs a significant amount of heat in the process. As warm cabin air is blown over the cold evaporator fins by the blower fan, the air temperature drops, and moisture condenses on the fins and is drained away. The Shacman DZ13241821111 assembly is designed as a complete, ready-to-install unit, often including the thermal expansion valve (TXV) or orifice tube connection points and mounting brackets, ensuring a perfect fit and seamless integration with the specific Shacman truck model’s HVAC system.

| Parameter | Specification |

|---|---|

| OEM Part Number | DZ13241821111 |

| Component Name | Evaporator Core Assembly |

| Brand | Shacman |

| Core Material | Aluminum Tubes and Fins (Most Common) |

| Type | Plate-Fin or Tube-Fin Heat Exchanger |

| Refrigerant Type | R134a or R1234yf (as per Vehicle Design) |

| Connections | Inlet/Outlet for Refrigerant, Drain Tube Port |

| Pressure Rating | Designed for A/C System Operating Pressure |

| Compatibility | Shacman X3000, F3000 Series with Factory A/C |

The evaporator assembly DZ13241821111 is where the actual cooling of the cabin air takes place. High-pressure liquid refrigerant from the condenser passes through a metering device (TXV or orifice tube) and enters the evaporator as a low-pressure, cold mist.

As the blower motor forces warm interior air across the evaporator’s extensive finned surface, the refrigerant inside the tubes absorbs the heat from the air. This causes the refrigerant to boil and evaporate into a low-pressure gas.

The heat absorption process dramatically lowers the temperature of the air passing over the fins. Simultaneously, moisture in the warm air condenses on the cold evaporator coils, effectively dehumidifying the air before it enters the cabin.

The dehumidification function is critical for comfort and safety. Dry air feels cooler and reduces clamminess. More importantly, it prevents fogging on the windshield and side windows, which is essential for maintaining driver visibility in humid conditions.

Condensed water drains from the evaporator housing via a dedicated drain tube, which must be kept clear to prevent water accumulation inside the HVAC case, which can lead to mold, mildew, and unpleasant odors.

The DZ13241821111 utilizes aluminum for its excellent thermal conductivity, lightweight properties, and corrosion resistance. The tubes are arranged in a serpentine pattern to maximize the surface area exposed to airflow.

Thin aluminum fins are mechanically or chemically bonded to the tubes. These fins greatly increase the heat transfer area, allowing for efficient cooling even with a compact core size that fits within the dashboard constraints.

The entire assembly is housed in a robust plastic or metal casing that directs airflow and channels condensate to the drain. The casing is designed to minimize air leaks, ensuring all cabin air is forced through the evaporator core.

The aluminum components are often treated with protective coatings to resist corrosion from moisture and acidic condensate. This is vital for preventing pinhole leaks that would cause refrigerant loss and system failure.

A clean and unobstructed evaporator surface is key to longevity. The use of a cabin air filter (where equipped) helps protect the evaporator from being coated with dust and debris, which insulates the fins and reduces efficiency.

The evaporator assembly is mounted inside the HVAC plenum chamber, typically behind the glove box or center dashboard area. It is positioned upstream of the blend air door and heater core.

Its inlet and outlet connections are brazed or fitted with O-rings to the refrigerant lines leading to the compressor and condenser. A proper, leak-free connection here is critical for system integrity and performance.

The assembly works in concert with the system’s pressure sensors, thermostatic expansion valve (TXV), and compressor clutch cycle to maintain optimal cooling power without freezing the evaporator core.

The most common failure is leakage, leading to a gradual loss of refrigerant and diminished cooling. A musty smell from the vents often indicates microbial growth on a wet evaporator due to a clogged drain.

Reduced airflow can occur if the fins are physically blocked by debris. Ice formation on the evaporator coils, often due to low refrigerant or a faulty TXV, can also block airflow and cause the system to blow warm air.

A fully functional evaporator is essential for maintaining a temperature-controlled cabin. This prevents heat stress and fatigue, allowing the driver to remain alert and focused during long journeys, especially in hot climates.

By effectively removing humidity, the assembly plays a direct role in safety. Clear windows are non-negotiable for safe operation, and the evaporator is the primary component that keeps them fog-free.

Consistent cooling performance also protects sensitive electronic devices and paperwork that may be inside the cabin from extreme heat and moisture damage.

The evaporator is a sealed component with no moving parts, requiring no routine maintenance itself. However, maintaining the overall A/C system (clean filters, proper refrigerant charge) extends its life.

Replacement of the DZ13241821111 is a significant job, as it requires evacuating the refrigerant, dismantling parts of the dashboard to access the HVAC case, and then opening the case to replace the core.

It is a job for qualified technicians. After replacement, the system must be properly vacuumed, recharged with the correct amount and type of refrigerant and oil, and tested for leaks and performance.

Using the genuine Shacman DZ13241821111 ensures perfect thermal capacity, physical dimensions, and connection compatibility. An incorrect evaporator can lead to poor cooling, improper refrigerant flow, or physical damage during installation.

Genuine parts also guarantee the material quality and corrosion resistance needed for the long service life expected in a commercial vehicle, preventing premature failure and a repeat of the costly replacement procedure.

A clean, efficient evaporator core reduces the workload on the A/C compressor. This leads to lower fuel consumption, as the compressor draws less power from the engine, and extends the compressor’s lifespan.

A properly functioning system with no leaks ensures that refrigerant, which is a potent greenhouse gas, is contained within the system, minimizing environmental impact. The DZ13241821111 is designed for reliability to support this.

Modern evaporator designs aim for maximum heat exchange with minimal internal volume, reducing the required refrigerant charge while maintaining performance, aligning with global trends towards more efficient systems.

Each Shacman evaporator assembly DZ13241821111 undergoes rigorous testing. This includes pressure testing to ensure there are no leaks in the tubing and fin-to-tube bond integrity checks.

The manufacturing process controls the cleanliness of the internal passages to prevent contamination that could clog the TXV or damage the compressor. This level of quality control is essential for a component that is so difficult to replace.

By meeting Shacman’s strict OE specifications, this part guarantees that the A/C system will perform as originally designed, providing consistent cooling capacity and reliability.

Choosing the genuine DZ13241821111 is a decision for long-term reliability and performance. It is the only part engineered to match the specific thermal load and airflow characteristics of your Shacman truck’s cabin.

Aftermarket evaporators may have different fin densities, tube lengths, or internal volumes, leading to incorrect superheat values, poor dehumidification, or even compressor damage due to liquid slugging.

Given the labor-intensive replacement process, investing in the genuine part from the start ensures you won’t have to repeat the job prematurely, saving significant time and money over the life of the truck.

The Shacman Evaporator Assembly, OEM number DZ13241821111, is the silent workhorse at the heart of your truck’s air conditioning system. Its efficient heat exchange and dehumidification are fundamental to cabin comfort, driver safety, and overall vehicle functionality.

When repair is necessary, selecting this genuine component is the most reliable way to restore factory cooling performance and durability. It is a critical investment in the well-being of the driver and the operational readiness of the vehicle.

For accurate diagnosis, compatibility confirmation, or to source this essential A/C component, please use the contact methods provided. Trust the genuine part to bring cool, dry comfort back to your Shacman truck’s cabin.