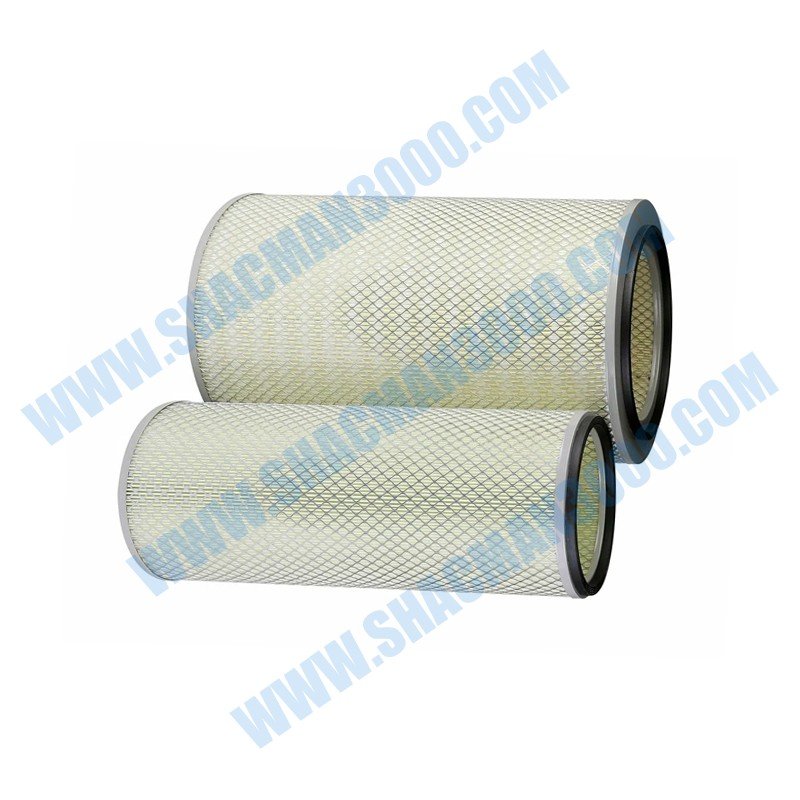

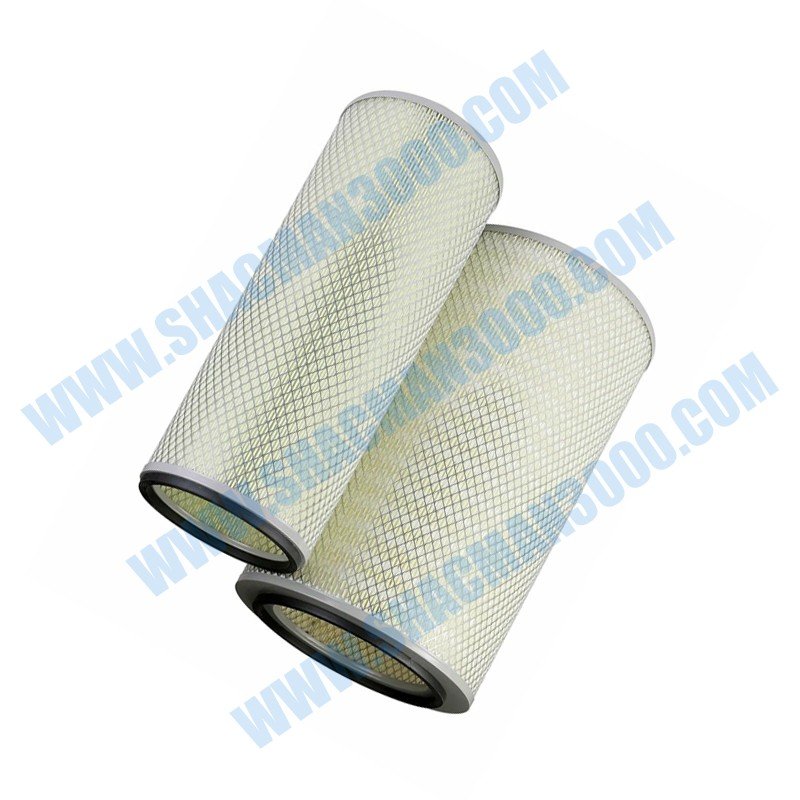

Air Filter 3052 Wp12

Воздушный фильтр 3052 Wp12

Filtro de Aire 3052 Wp12

The Shacman Air Filter with OEM number DZ9112190328-1 represents the pinnacle of engine protection technology for WP12 engines in heavy-duty commercial vehicles. This premium air filtration component, specifically designed as model 3052 for WP12 engines, ensures optimal engine performance and longevity by providing superior contaminant removal from intake air. The genuine Shacman part number DZ9112190328-1 guarantees perfect compatibility and reliable filtration performance under the most demanding operating conditions encountered in various environmental conditions and industrial applications.

This advanced air filter plays a critical role in protecting the sophisticated WP12 engine from harmful airborne contaminants that can cause accelerated wear and reduced performance. Manufactured using high-efficiency filter media with advanced pleating technology, the DZ9112190328-1 air filter delivers exceptional dust-holding capacity and filtration efficiency. Its specialized design ensures consistent airflow while maintaining maximum protection, contributing to improved fuel efficiency and reduced maintenance costs for heavy-duty vehicles operating in challenging environments with high particulate concentrations.

| Parameter | Details |

|---|---|

| OEM Number | DZ9112190328-1 |

| Brand | Shacman |

| Product Name | Air Filter 3052 |

| Engine Compatibility | WP12 Series |

| Filtration Efficiency | 99.9% at 5 microns |

| Initial Restriction | ≤ 1.5 kPa |

| Maximum Restriction | 6.0 kPa |

| Dust Holding Capacity | ≥ 800 grams |

| Service Life | Up to 50,000 km |

The Shacman Air Filter 3052 WP12 with OEM number DZ9112190328-1 represents cutting-edge filtration technology specifically engineered for heavy-duty diesel engines operating in challenging environments. This high-performance air filter serves as the first line of defense for WP12 engines, protecting critical internal components from abrasive particles and contaminants that can cause significant engine damage and reduced operational efficiency over time.

Manufactured according to strict OEM specifications, this air filter guarantees perfect compatibility with WP12 engine air intake systems in Shacman commercial vehicles. The advanced filter media construction provides exceptional filtration performance while maintaining optimal airflow characteristics essential for engine combustion efficiency and power output. The specialized sealing system ensures complete protection against unfiltered air bypass, maintaining engine protection throughout the filter’s service life in various operating conditions.

The air filter incorporates advanced multi-layer filtration media with precisely controlled pore structure that provides superior particle capture efficiency while maintaining low airflow restriction. The specialized media treatment enhances dust release properties and moisture resistance, ensuring consistent performance in various environmental conditions. This technological advancement represents Shacman’s commitment to engine protection and performance optimization in commercial vehicle applications.

The Shacman Air Filter DZ9112190328-1 offers numerous technical advantages for WP12 engine protection and performance optimization. Its high-efficiency filter media provides exceptional contaminant removal capabilities, capturing 99.9% of particles as small as 5 microns that could potentially damage engine components. The precision manufacturing ensures perfect fitment and sealing within the air intake system, preventing unfiltered air bypass and ensuring complete engine protection throughout the filter’s service interval.

Significant performance benefits include improved engine longevity and reduced maintenance costs through superior protection against abrasive wear. The optimized airflow characteristics contribute to better combustion efficiency and fuel economy, while the high dust-holding capacity extends service intervals in dusty operating conditions. These engineered features combine to deliver reliable, consistent performance in demanding heavy-duty applications across various industries and environmental conditions.

The advanced filtration media provides comprehensive protection for critical engine components including turbochargers, cylinders, and pistons against abrasive particles that cause accelerated wear. The multi-stage filtration process captures contaminants progressively, maintaining high efficiency throughout the filter’s service life. This enhanced protection translates to extended engine life, reduced oil contamination, and lower overall operating costs for commercial vehicle operators.

The precisely engineered pleat design and media characteristics ensure optimal airflow with minimal restriction, supporting maximum engine power output and combustion efficiency. The low initial pressure drop reduces parasitic load on the engine, contributing to improved fuel economy and performance. This airflow optimization is particularly important for WP12 engines operating under heavy loads and in high-altitude conditions where air density variations affect performance.

The comprehensive technical specifications of the Air Filter 3052 WP12 DZ9112190328-1 highlight its superior engineering quality and performance characteristics. The high-efficiency cellulose and synthetic blend media composition provides optimal filtration performance with excellent durability and moisture resistance. The component undergoes rigorous quality control procedures to verify filtration efficiency, structural integrity, and dimensional accuracy before installation in Shacman air intake systems.

The air filter features precisely engineered end caps and sealing surfaces that ensure perfect fitment and prevent air bypass in the housing assembly. All critical sealing areas undergo specialized treatment to maintain flexibility and sealing performance throughout temperature variations and service life. The robust construction withstands pressure pulsations and vibration encountered in heavy-duty vehicle operations, ensuring reliable performance across various operating conditions and environmental challenges.

The specialized filter media combines cellulose fibers with synthetic reinforcement to achieve optimal filtration characteristics and mechanical strength. The media treatment includes specialized resins that enhance moisture resistance and dust release properties, maintaining performance in high-humidity conditions. The optimized media construction provides consistent performance throughout the filter’s service life, ensuring reliable engine protection in various operating environments and application scenarios.

The Shacman Air Filter 3052 WP12 DZ9112190328-1 is specifically engineered for Shacman trucks and equipment powered by WP12 series engines. It finds application across various demanding sectors including long-haul transportation, construction, mining, agriculture, and specialized vocational vehicles. The component is critically important for maintaining engine performance and reliability in environments with high particulate concentrations and challenging operating conditions.

This precision air filter is essential for routine maintenance programs, engine overhauls, and preventive maintenance schedules in commercial fleet operations. It is routinely replaced during scheduled service intervals according to manufacturer recommendations and established maintenance best practices. The part ensures reliable engine protection in both standard and severe service conditions, making it a crucial component for comprehensive fleet maintenance programs focused on maximizing vehicle uptime and operational efficiency.

Within the transportation industry, this air filter helps maintain engine reliability across extended mileage and demanding routes with varying environmental conditions. Construction companies depend on its performance in equipment operating in dusty job sites with high particulate concentrations. Mining operations benefit from its exceptional filtration efficiency in abrasive environments with high silica dust levels. Agricultural applications utilize its reliable performance during harvesting and planting seasons with elevated organic particulate levels.

Proper installation of the Shacman Air Filter DZ9112190328-1 is absolutely crucial for achieving optimal filtration performance and engine protection. Begin by thoroughly cleaning the air filter housing and intake system components using appropriate cleaning methods and approved cleaning solutions. Remove any previous filter elements completely and conduct careful inspection of the housing for damage, cracks, or sealing surface imperfections that could compromise filtration efficiency.

Position the new air filter carefully in the housing while ensuring proper orientation according to manufacturer specifications and service manual guidelines. Verify perfect seating of the filter element and inspect the sealing surfaces for complete contact without gaps or misalignment. Install the housing cover and secure all fasteners according to exact manufacturer torque specifications and sequences for optimal results and reliable performance. Always refer to current Shacman service manuals for detailed installation procedures.

Experienced maintenance technicians strongly recommend comprehensive inspection of the entire air intake system for leaks, damage, or contamination before installation. Replace all related components if significant wear or damage is detected during the inspection process to prevent system contamination. Utilize proper service procedures and tools to prevent damage to the filter element during installation and ensure correct positioning within the air filter housing for optimal performance.

Regular systematic maintenance of the air filtration system significantly extends engine life and ensures operational reliability throughout the vehicle’s service life. Continuously monitor air filter restriction indicators and engine performance parameters for early signs of filter loading or system issues that could indicate reduced filtration efficiency. Check for visual indicators and service interval recommendations based on operating conditions and environmental factors affecting filter life.

Conduct thorough air filter inspections during scheduled maintenance intervals or when performance issues arise during normal operation. Look for visual signs of contamination, damage, or improper sealing that could compromise filtration performance. Verify proper restriction levels and compare with manufacturer specifications to determine appropriate replacement timing. Maintain detailed maintenance records to accurately track replacement intervals and operating conditions for predictive maintenance planning.

Implement comprehensive preventive maintenance schedules based on accumulated mileage, engine operating hours, or specific environmental conditions according to manufacturer guidelines and industry best practices. Use only manufacturer-recommended replacement intervals and inspection procedures that account for actual operating conditions and dust exposure levels. Provide technician training for proper inspection techniques, replacement procedures, and system integrity verification for optimal engine protection and performance.

Selecting genuine Shacman parts like the Air Filter DZ9112190328-1 ensures optimal performance characteristics, perfect compatibility, and reliable engine protection for WP12 engines in commercial vehicles. These components are specifically engineered for Shacman trucks and undergo rigorous validation testing under simulated operating conditions that replicate real-world environmental challenges and performance requirements. Genuine parts maintain full vehicle warranty coverage and provide perfect dimensional fitment during installation procedures.

Genuine Shacman parts deliver exceptional long-term value through consistent performance, reliable engine protection, and minimized operational downtime in commercial applications. They are supported by Shacman’s comprehensive technical expertise, extensive service network, and global support infrastructure for parts and service requirements. Using genuine components protects your engine investment, maintains optimal performance standards, and ensures consistent reliability across your fleet operations for maximum profitability and operational efficiency.

Every genuine Shacman part undergoes multiple comprehensive quality control procedures throughout the manufacturing process, from raw material selection to final performance validation. Filter media materials are sourced from certified suppliers meeting international quality standards and performance specifications with full traceability and documentation. Manufacturing processes include numerous inspection points throughout production stages to ensure consistent quality, dimensional accuracy, and performance characteristics in every component produced.

The Air Filter plays a fundamentally critical role in overall engine performance optimization, operational efficiency, and long-term reliability in heavy-duty commercial vehicles. Understanding its precise function, performance characteristics, and maintenance requirements facilitates proper maintenance planning and execution for fleet managers, maintenance supervisors, and service professionals. This component directly affects engine longevity, fuel efficiency, emissions performance, and overall operating costs in commercial vehicle operations.

For optimal SEO performance and comprehensive customer information, this description naturally incorporates relevant technical keywords, detailed product specifications, and practical application guidance. The content provides detailed technical information to assist informed purchasing decisions, proper maintenance procedures, and effective fleet management practices for maintenance professionals and fleet managers. Using genuine Shacman parts supports sustainable operational practices by extending engine life and reducing environmental impact through optimized performance.

Genuine Shacman parts are designed for maximum performance efficiency, engine protection, and environmental responsibility throughout their complete lifecycle in commercial vehicle applications. Proper air filtration maintenance helps engines operate more efficiently, contributing to reduced fuel consumption, lower emissions, and improved sustainability in commercial transportation operations. Extended engine life through superior protection means reduced resource consumption and environmental impact from manufacturing and disposal processes.

Q: What is the recommended replacement interval for the Air Filter? A: Replace every 50,000 km under normal conditions, or more frequently in severe dust conditions, following manufacturer recommendations.

Q: Can I clean and reuse this air filter? A: This is a disposable filter element designed for single use; cleaning and reusing is not recommended as it compromises filtration efficiency.

Q: Is part number DZ9112190328-1 compatible with all WP12 engines? A: It is specifically engineered for WP12 series engines in Shacman truck applications; verify compatibility with specific models.

Q: What operational signs indicate air filter replacement is needed? A: Reduced engine power, black smoke, increased fuel consumption, or restriction indicator activation may signal the need for replacement.

Thank you for reviewing our comprehensive technical product overview. For additional information about the Shacman Air Filter 3052 WP12 DZ9112190328-1, explore our technical resources, service manuals, or contact us through the provided communication channels. We remain committed to supporting your Shacman truck maintenance requirements with genuine, high-quality filtration components and professional technical support services for optimal engine performance and reliability in all operating conditions.