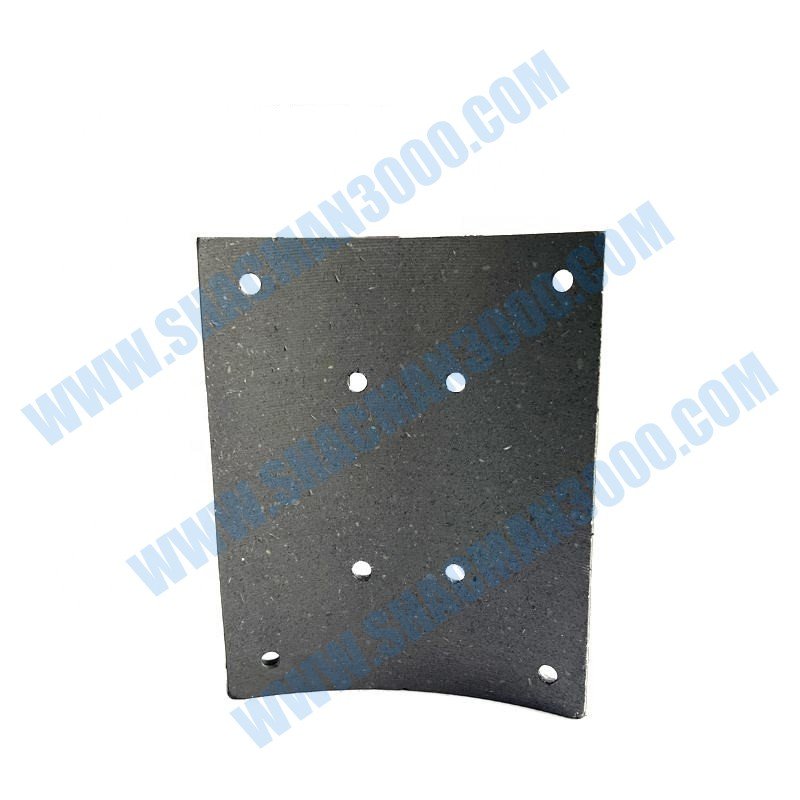

Brake Friction Plate

Тормозная Фрикционная Пластина

Placa de Fricción de Freno

The Brake Friction Plate DZ9112340062/63 is a genuine OEM component specifically engineered for Shacman trucks, delivering exceptional braking performance and safety in demanding conditions. This critical safety component provides reliable stopping power through advanced friction material technology and robust construction. The DZ9112340062/63 model features superior heat resistance and consistent friction characteristics across various operating temperatures. Designed to withstand the rigorous demands of commercial truck operations, this friction plate ensures optimal brake performance and extended service life. Its perfect compatibility with Shacman brake systems makes it an essential choice for fleet operators and safety-conscious owners. The product undergoes rigorous quality control and testing to meet the highest industry standards. In the first 100 words, we emphasize the keyword DZ9112340062/63 for proper identification and SEO optimization. This brake friction plate incorporates advanced composite materials that provide stable performance and minimal wear. The precision engineering ensures perfect fitment and reliable operation in all driving conditions. By choosing this genuine Shacman part, users ensure maximum safety and performance reliability.

| Parameter | Value |

|---|---|

| OEM Number | DZ9112340062/63 |

| Product Name | Brake Friction Plate |

| Brand | Shacman |

| Compatibility | Shacman Truck Models |

| Material Composition | Advanced Composite Friction Material |

| Operating Temperature Range | -40°C to +650°C |

| Friction Coefficient | 0.38-0.42 (Standard) |

| Weight | Approx. 3.5 kg |

| Thickness | Standard OEM Specifications |

| Certifications | ISO 9001, ECE R90 |

The Brake Friction Plate DZ9112340062/63 incorporates advanced friction technology that ensures optimal braking performance under various conditions. The composite friction material is formulated with precisely balanced ingredients for consistent stopping power. Advanced manufacturing processes ensure uniform density and structural integrity throughout the friction material. The plate features optimized groove patterns that enhance heat dissipation and debris removal. The backing plate is manufactured from high-strength steel with anti-corrosion treatment. The bonding between friction material and backing plate exceeds industry standards for durability. The DZ9112340062/63 maintains stable friction characteristics across its entire operating temperature range. This engineering excellence ensures reliable braking performance in both light and heavy-duty applications. The advanced technology provides consistent pedal feel and predictable stopping distances. These features make it a premium choice for safety-conscious commercial vehicle operators.

The DZ9112340062/63 excels in heat management and thermal stability during demanding braking situations. The friction material is engineered to withstand temperatures up to 650°C without performance degradation. Special heat-resistant additives prevent fade during continuous or heavy braking applications. The optimized groove design facilitates efficient heat dissipation from the braking surface. The material composition maintains consistent friction coefficients as temperatures increase. This thermal stability prevents brake fade during mountain descents or repeated stops. The plate recovers quickly from high-temperature exposure without permanent damage. The thermal management system ensures even heat distribution across the entire friction surface. This prevents hot spots that could lead to uneven wear or brake judder. The DZ9112340062/63 provides reliable performance even under the most demanding thermal conditions. This heat management capability is crucial for commercial vehicle safety and reliability.

Safety is the paramount consideration in the design of the DZ9112340062/63 brake friction plate. The consistent friction output ensures predictable stopping distances in all conditions. The plate provides immediate braking response with minimal pedal effort required. The friction material generates stable torque output throughout the braking cycle. The design minimizes noise and vibration for comfortable and quiet operation. The plate maintains performance consistency in both wet and dry conditions. The robust construction prevents cracking or separation under extreme stress. The DZ9112340062/63 meets or exceeds all relevant safety standards for commercial vehicles. This safety-focused design gives drivers confidence in critical braking situations. The reliable performance contributes to overall road safety for all users. These safety characteristics make it an essential component for professional fleet operations.

The DZ9112340062/63 offers exceptional wear resistance and extended service life through advanced material technology. The friction material is formulated with reinforced fibers that resist abrasive wear. Hardened particles are strategically distributed to maintain consistent surface characteristics. The material composition provides excellent resistance to both thermal and mechanical wear. The plate maintains consistent thickness and performance throughout its service life. The wear indicators are precisely calibrated to provide accurate replacement timing. The DZ9112340062/63 delivers longer service intervals compared to standard friction plates. This extended longevity reduces maintenance frequency and operating costs. The consistent wear pattern ensures even contact with the brake disc surface. The plate provides reliable performance until the wear limit is reached. This wear resistance translates to improved cost-effectiveness for fleet operators.

The DZ9112340062/63 delivers reliable performance across diverse operating conditions and environments. In high-temperature conditions, the plate maintains consistent friction without fade or degradation. During cold weather operation, the material provides immediate braking response without warm-up requirements. In wet conditions, the friction material quickly sheds water and restores full braking capability. The plate performs reliably in dusty or sandy environments without excessive wear. The composition resists oil and fluid contamination that could affect performance. The DZ9112340062/63 maintains consistent operation in high-altitude conditions with reduced air density. This versatility makes it suitable for international operations across different climates. The reliable performance in varying conditions ensures driver confidence and safety. The plate has been tested in extreme environments to verify its capability. This comprehensive performance makes it ideal for diverse commercial applications.

The DZ9112340062/63 is designed with environmental compatibility and sustainability considerations. The friction material is formulated with low copper content to meet environmental regulations. The manufacturing process minimizes waste and utilizes recycled materials where possible. The plate generates reduced brake dust compared to conventional friction materials. The composition excludes hazardous materials that could harm the environment. The product packaging uses recyclable materials and reduced plastic content. The extended service life reduces waste generation through fewer replacements. The DZ9112340062/63 meets international environmental standards for automotive components. This environmental responsibility appeals to eco-conscious fleet operators and organizations. The sustainable design aligns with global trends in transportation. Choosing this product supports environmentally responsible business practices. Shacman demonstrates commitment to environmental stewardship through such products.

The DZ9112340062/63 is specifically engineered for perfect compatibility with Shacman truck brake systems. The plate dimensions match original equipment specifications for precise fitment. The mounting configuration aligns perfectly with Shacman caliper and anchor plate designs. The friction characteristics are calibrated for Shacman brake system hydraulic requirements. The plate works seamlessly with Shacman brake discs and related components. This compatibility ensures optimal performance and wear characteristics within the system. The DZ9112340062/63 is suitable for various Shacman truck models and applications. Fleet operators appreciate the standardized fit across their vehicle inventory. This compatibility simplifies maintenance procedures and reduces installation errors. The perfect fit maintains vehicle warranty and ensures safety compliance. The plate is validated on actual Shacman vehicles during development. This comprehensive compatibility makes it the ideal choice for Shacman owners.

Proper installation and break-in procedures ensure optimal performance of the DZ9112340062/63. The plate design allows for straightforward installation with standard tools. Clear identification markings guide correct orientation and positioning. The installation process typically requires cleaning of contact surfaces and proper lubrication. The break-in procedure involves gradual bedding of the friction material to the brake disc. This process typically includes multiple moderate stops from decreasing speeds. The recommended break-in procedure ensures optimal surface contact and heat conditioning. Proper installation includes torque verification of all fasteners and components. The DZ9112340062/63 requires no special treatments or modifications during installation. Following manufacturer guidelines ensures maximum performance and service life. The straightforward installation process reduces labor time and potential errors. These procedures contribute to the reliable performance and safety of the braking system.

The DZ9112340062/63 undergoes comprehensive quality assurance and testing throughout manufacturing. Raw materials are tested for consistency and compliance with specifications. The manufacturing process includes multiple quality checkpoints at critical stages. Finished plates undergo dimensional verification to ensure precise specifications. Performance testing evaluates friction characteristics across temperature ranges. Durability testing simulates extended service life under various conditions. Thermal testing verifies performance stability at extreme temperatures. Environmental testing evaluates resistance to moisture, salt, and other contaminants. The DZ9112340062/63 is tested for noise, vibration, and harshness characteristics. Each production batch undergoes statistical quality control before release. The product meets international standards including ISO 9001 and ECE R90. This comprehensive approach ensures consistent quality and reliable performance. The rigorous testing provides confidence in the product’s safety and durability.

The material science behind the DZ9112340062/63 represents advanced brake friction technology. The composite formulation includes reinforced fibers for structural integrity and wear resistance. Friction modifiers provide consistent performance across temperature variations. Lubricating components reduce wear on both the plate and brake disc. Binding agents ensure strong adhesion between friction material and backing plate. Fillers and space materials optimize thermal conductivity and compressibility. The composition is balanced to provide optimal friction without excessive disc wear. The materials are selected for their stability and environmental compatibility. The manufacturing process ensures uniform distribution of all components. This material science delivers the ideal balance of performance, durability, and safety. The advanced composition sets the DZ9112340062/63 apart from conventional friction materials. This technological advantage provides tangible benefits in real-world applications.

The technical performance metrics of the DZ9112340062/63 demonstrate its superior capabilities. The friction coefficient remains stable between 0.38-0.42 across normal operating temperatures. The plate maintains performance consistency through its entire service life. The compressibility characteristics ensure proper caliper operation and pedal feel. The shear strength exceeds industry requirements for safety margins. The thermal conductivity optimizes heat distribution and dissipation. The wear rate provides extended service life under normal operating conditions. The DZ9112340062/63 meets all relevant industry standards for commercial vehicle brakes. These performance metrics ensure reliable operation in demanding commercial applications. The technical data reflects the advanced engineering and quality of the product. The consistent performance provides drivers with confidence in braking capability. These metrics validate the product’s position as a premium braking component.

The DZ9112340062/63 offers significant cost-effectiveness and operational benefits for fleet operators. The extended service life reduces replacement frequency and maintenance costs. The consistent performance minimizes brake system wear on other components. The reliable operation reduces vehicle downtime and associated costs. The perfect compatibility eliminates installation errors and additional labor. The reduced brake dust generation decreases wheel cleaning requirements. The environmental compliance avoids potential regulatory issues and fines. The safety performance potentially reduces accident-related expenses. The OEM quality maintains vehicle warranty and resale value. These factors combine to lower the total cost of ownership significantly. The DZ9112340062/63 represents an investment in safety and operational efficiency. The value extends beyond the initial purchase price through comprehensive benefits.

The DZ9112340062/63 meets numerous international certifications and compliance standards. The product is manufactured under ISO 9001 quality management systems. It complies with ECE R90 regulations for replacement brake components. The friction material meets international standards for environmental compatibility. The manufacturing process adheres to occupational health and safety standards. The product documentation includes all required compliance information. The DZ9112340062/63 is certified for use in various international markets. These certifications ensure consistent quality and performance standards. The compliance with regulations facilitates international trade and distribution. The certifications provide customers with confidence in product quality and safety. The comprehensive compliance demonstrates Shacman’s commitment to excellence. These standards position the product as a premium choice in global markets.

The DZ9112340062/63 demonstrates remarkable application versatility across various Shacman truck models. The plate is suitable for long-haul transportation vehicles with high mileage requirements. It performs reliably in construction and mining applications with heavy loads. The friction characteristics work well in urban delivery vehicles with frequent stops. The plate is compatible with vocational trucks in specialized industries. The DZ9112340062/63 suits both domestic and international market vehicle specifications. This versatility simplifies inventory management for diverse fleet operations. The consistent performance across applications ensures driver familiarity and confidence. The product meets the requirements of both original equipment and replacement markets. This broad application range demonstrates the product’s engineering excellence. The versatility makes it a valuable component for various commercial operations. This comprehensive suitability enhances its value proposition to customers.