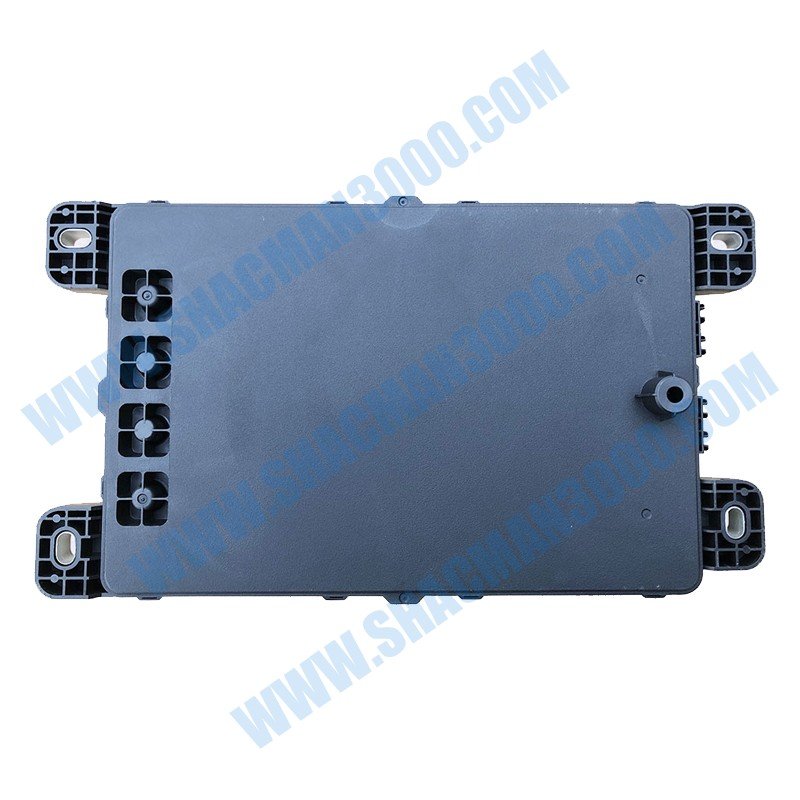

Fuse Box

Блок предохранителей

Caja de Fusibles

The genuine Shacman Fuse Box with OEM number DZ97189584260 delivers exceptional electrical system protection for heavy-duty truck applications. This critical electrical component ensures reliable circuit protection and prevents electrical system damage under various operating conditions.

Manufactured to exact OEM specifications using premium materials, the DZ97189584260 fuse box provides reliable performance in demanding environments. The precision engineering guarantees perfect fitment and extended service life for Shacman electrical systems.

With advanced circuit protection design and corrosion-resistant construction, this fuse box offers superior electrical safety and durability. Regular maintenance with genuine components ensures optimal electrical system performance and prevents costly electrical failures.

| Parameter | Specification |

|---|---|

| OEM Part Number | DZ97189584260 |

| Product Name | Fuse Box |

| Brand | Shacman |

| Material | High-Temperature Plastic |

| Number of Circuits | 24 Circuits |

| Maximum Current | 100A Total |

| Operating Temperature | -40°C to +85°C |

| IP Rating | IP65 |

| Compatibility | Shacman Truck Series |

The Shacman Fuse Box provides comprehensive electrical circuit protection for all vehicle systems. This critical component prevents electrical overloads and short circuits that could damage sensitive electronic components.

Precision-engineered current paths ensure reliable protection and minimize voltage drops. The design maintains stable electrical performance throughout the vehicle’s operating range.

Manufactured from high-temperature resistant plastic materials, this fuse box offers excellent resistance to heat and environmental stress. The robust construction withstands vibration and thermal cycling.

Advanced material formulations provide superior resistance to UV radiation, chemicals, and moisture. The IP65 rating ensures protection against dust and water ingress.

Each DZ97189584260 fuse box undergoes rigorous quality control procedures throughout manufacturing. Precise dimensional accuracy guarantees perfect fitment and connector alignment.

Computer-aided design and manufacturing processes ensure consistent product quality and electrical performance. Engineering specifications meet original equipment requirements for reliability.

This genuine Shacman component is specifically engineered for heavy-duty truck electrical systems. The fuse box ensures optimal performance across various vehicle configurations and electrical loads.

Proper installation maintains factory specifications for electrical system protection and circuit management. Vehicle operators can expect reliable electrical performance and prevention of system failures.

The Fuse Box performs reliably in diverse environmental conditions and electrical load scenarios. From extreme temperature variations to high-vibration environments, this component maintains electrical integrity.

The design accounts for varying electrical loads, voltage fluctuations, and environmental exposure. Long-haul transportation and construction applications benefit from this durable electrical component.

Shacman implements stringent quality control measures throughout the entire production process. Each fuse box undergoes multiple inspection stages before packaging.

Advanced testing equipment verifies dimensional accuracy, material properties, and electrical performance. The manufacturing facility maintains ISO certification for quality management systems.

Comprehensive laboratory testing simulates real-world operating conditions to ensure reliability. Electrical testing exceeds standard requirements for safety margins.

Environmental testing verifies performance under extreme temperature and humidity conditions. The results confirm the product’s capability in demanding electrical system applications.

Proper installation requires careful handling and correct electrical connections for optimal results. Technicians should follow manufacturer-recommended procedures during assembly.

Electrical connectors must be clean and properly seated before installation. Professional installation ensures proper electrical contact and prevents connection issues.

Regular visual inspections during routine maintenance help identify potential issues early. Check for signs of corrosion, cracks, or loose connections during service intervals.

Fuse ratings should be verified according to manufacturer specifications. Replacement is recommended when inspection reveals damage or electrical issues.

The optimized design ensures reliable circuit protection for all vehicle electrical systems. Properly functioning fuse boxes prevent electrical damage and system failures.

The component’s electrical efficiency contributes to stable system voltage and current distribution. This protects sensitive electronic components and extends overall electrical system lifespan.

Maintaining proper electrical protection directly impacts vehicle reliability and operational safety. Effective fuse systems reduce electrical failures and downtime.

The precise engineering minimizes electrical resistance and voltage drops. This contributes to overall vehicle efficiency and reduced electrical system maintenance.

Shacman stands behind the quality of every genuine component manufactured. The Fuse Box comes with comprehensive warranty coverage.

This commitment reflects the manufacturer’s confidence in product reliability and durability. Customers receive full support for any manufacturing defects.

Professional technical assistance remains available for installation guidance and troubleshooting needs. Shacman’s network provides expert support when required.

Comprehensive documentation accompanies each product for reference and guidance. Customers can access additional resources through authorized service centers.

Regular inspection during scheduled maintenance helps identify wear before failure occurs. Visual checks should include connection condition and housing integrity.

Replacement timing depends on operating conditions and environmental exposure factors. Severe service applications may require more frequent inspection intervals.

Professional installation by qualified technicians ensures optimal performance and system integrity. Certified workshops have proper equipment for correct installation.

Proper electrical testing and circuit verification are essential after replacement. This ensures the electrical system functions as designed by the manufacturer.

All raw materials undergo rigorous certification processes before production begins. Plastic compounds meet automotive standards for electrical applications.

Metal contacts and terminals are tested for conductivity and corrosion resistance. Material traceability ensures consistent quality across production batches.

State-of-the-art manufacturing equipment ensures precision and consistency in production. Automated processes maintain tight tolerances and dimensional accuracy.

Each production stage includes quality checks and verification procedures. Final inspection confirms all specifications are met before packaging and shipping.

Ideal for long-haul trucks operating under continuous heavy loads with complex electrical systems. The fuse box provides reliable protection for vehicles in demanding transportation.

The component maintains electrical system integrity during extended highway operation. Fleet operators benefit from consistent performance across different electrical loads.

Essential for equipment operating in demanding environments where electrical reliability is critical. The robust design handles challenging operating conditions.

Mining applications benefit from the component’s resistance to vibration, dust, and moisture. The durable construction ensures reliable electrical performance.

Proper electrical system maintenance with genuine components significantly extends vehicle operational lifespan. Effective circuit protection prevents electrical damage.

The fuse box’s durable construction contributes to overall electrical reliability and longevity. This translates to extended service life and improved return on investment.

Maintaining proper electrical protection ensures consistent vehicle performance and system reliability. Effective fuse protection reduces electrical system downtime.

The component’s precision engineering ensures reliable performance throughout its service life. Vehicle operators experience consistent electrical system operation.

Genuine Shacman components provide optimal protection that reduces long-term maintenance costs. Preventing electrical system damage offers significant economic benefits.

The initial investment in quality electrical parts pays dividends through extended service intervals. Fleet managers appreciate the predictable maintenance costs.

Reliable electrical components contribute to overall vehicle uptime and operational efficiency. This ensures business continuity for commercial operators.

The proven performance of genuine Shacman parts provides confidence in vehicle reliability. Operators can depend on consistent electrical system performance.

Always verify part number DZ97189584260 before purchase to ensure compatibility with your specific vehicle electrical system requirements.

Genuine Shacman parts meet exact engineering specifications and performance requirements for optimal electrical protection and system reliability.

Professional installation and regular maintenance inspections are essential for achieving optimal performance and ensuring electrical system integrity is maintained.