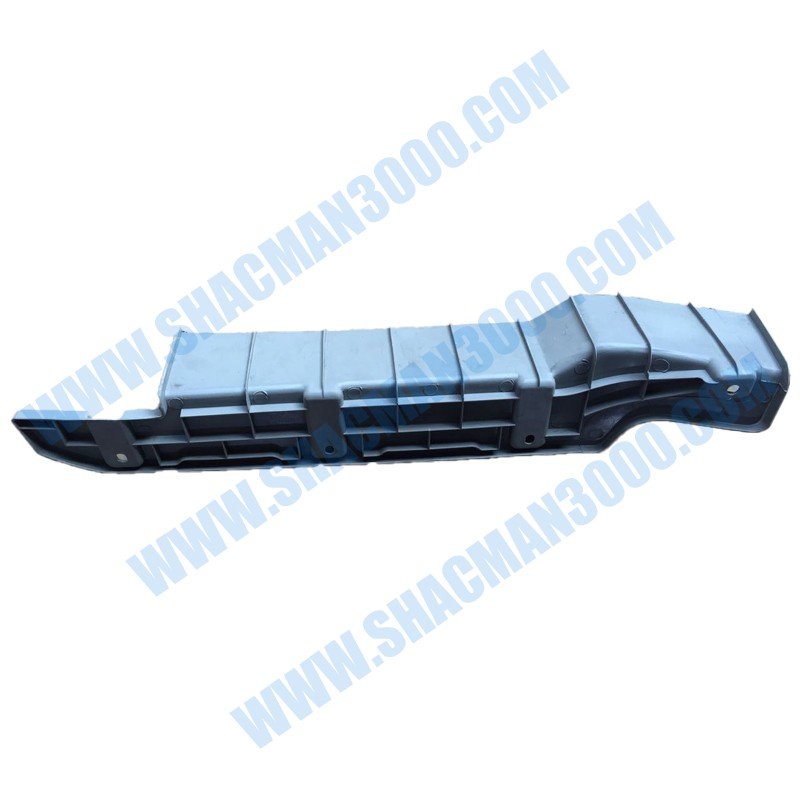

Front Bumper Junction Box Assembly

Сборка коробки соединения переднего бампера

Ensamblaje de la caja de unión del parachoques delantero

The Shacman Front Bumper Junction Box Assembly DZ97189777020 serves as the critical nerve center for all front-end electrical functions on heavy-duty trucks. This robust component, identified by OEM number DZ97189777020, consolidates wiring connections for headlights, turn signals, fog lamps, sensors, and other crucial frontal accessories into a single, protected unit. Engineered for durability, it features waterproof seals, corrosion-resistant terminals, and high-impact housing to withstand harsh road environments, vibration, and temperature fluctuations, ensuring reliable electrical distribution and circuit protection.

Precision-designed for direct OEM replacement, this junction box assembly guarantees perfect fitment and electrical compatibility with Shacman truck models. Its organized internal layout simplifies troubleshooting and maintenance, while its centralized design reduces wire clutter and potential failure points. The assembly enhances overall vehicle safety and functionality by providing a secure, organized, and easily accessible hub for the front lighting and electronic systems, which is essential for optimal performance in demanding commercial transportation operations.

| Parameter | Specification |

|---|---|

| OEM Number | DZ97189777020 |

| Product Name | Front Bumper Junction Box Assembly |

| Brand | Shacman |

| Compatible Models | Shacman F3000, M3000, X3000 Series |

| Housing Material | High-Strength Engineering Plastic (PP/PA66) |

| Sealing Rating | IP67 (Dustproof & Waterproof) |

| Terminal Material | Copper Alloy, Tin-Plated |

| Number of Circuits | 12+ (Configurable) |

| Fuse/Relay Integration | Integrated Holders for Standard Blade Fuses & Relays |

| Operating Voltage | 12V/24V DC System Compatible |

| Temperature Range | -40°C to +105°C |

| Mounting Type | Bracket-Mounted behind Front Bumper |

| Warranty | 18 Months |

The Front Bumper Junction Box Assembly DZ97189777020 acts as the primary distribution point for all front-end electrical loads. It efficiently routes power from the main vehicle harness to individual components like headlights, fog lamps, and turn signals. This centralized design eliminates messy wire splices and reduces the length of wiring runs. It ensures consistent voltage supply and minimizes electrical resistance across all connected circuits. The organized layout significantly simplifies the electrical architecture for easier manufacturing and service.

Integrated fuse and relay holders provide critical circuit protection directly at the source. This localized protection scheme isolates electrical faults quickly, preventing damage to upstream wiring and control modules. The logical grouping of circuits within the box aids technicians in rapid diagnosis and repair. Each terminal is clearly marked or coded for straightforward identification during installation or troubleshooting procedures. This function is vital for maintaining uptime in commercial fleet operations.

Engineered for the demanding environment behind the front bumper, this assembly boasts an IP67 sealing rating. The housing features multiple sealing gaskets and tight-fitting connectors that effectively block dust, dirt, and moisture ingress. This protection is crucial for preventing corrosion, short circuits, and electrical failures caused by water spray, road salt, and mud. The high-quality engineering plastic resists impacts from road debris and vibrations transmitted from the chassis.

Materials are selected for superior UV stability and resistance to automotive fluids like oil and coolant. The tin-plated copper terminals ensure a reliable, low-resistance connection that is highly resistant to oxidation over time. This robust construction guarantees long-term electrical integrity in extreme temperatures, from freezing winters to scorching summers, ensuring the front lighting system operates reliably in all conditions.

Designed as a direct OEM replacement, the DZ97189777020 assembly offers true plug-and-play compatibility. It comes with pre-assembled connectors that match the vehicle’s existing wiring harness perfectly. This eliminates the need for cutting, splicing, or modifying wires, which preserves the factory electrical system’s integrity and safety. The mounting brackets align precisely with the original points on the truck’s frame or bumper support.

Installation is straightforward, requiring only basic tools, which reduces vehicle downtime during replacement. The assembly restores the electrical system to its original designed state, ensuring all front-end lights and sensors function correctly with the correct amperage and voltage. This seamless integration is essential for maintaining the vehicle’s safety certifications and optimal performance.

The Shacman Front Bumper Junction Box Assembly DZ97189777020 is engineered for a range of Shacman heavy-duty truck models renowned for reliability in transport. Primary compatibility includes the versatile F3000 series, a workhorse for regional haulage and construction. This series benefits greatly from the organized and protected electrical management this box provides.

The M3000 series, designed for medium to heavy-duty applications, also utilizes this centralized junction box. Its design supports the electrical demands of various body configurations and auxiliary equipment. For the modern and efficient X3000 series trucks, this component is integral to the advanced electrical architecture that supports driver assistance features.

This assembly is critical for trucks operating in sectors like logistics, construction, and mining. Any application where the front bumper area is exposed to vibration, impacts, and harsh elements requires this robust junction box. It ensures that lighting systems for night operations and safety signals remain fully functional.

Fleet managers will find this part essential for standardizing repairs across their Shacman vehicle inventory. Its precise OEM fit guarantees that electrical repairs are consistent and reliable, reducing varied repair procedures. The part number DZ97189777020 should be referenced to ensure the correct assembly is sourced for the specific model and production year.

Every Front Bumper Junction Box Assembly DZ97189777020 is manufactured under strict quality control protocols aligned with Shacman’s standards. The production process begins with the selection of premium, automotive-grade polymers for the housing. These materials are tested for impact strength, flame retardancy, and long-term aging characteristics before use.

Injection molding is performed using precision tools that create parts with consistent wall thickness and dimensional accuracy. Each molded housing is inspected for defects such as flash, sink marks, or incomplete fills that could compromise the IP67 seal. The internal terminal boards are assembled using automated equipment to ensure correct placement and torque of all connectors and terminals.

Electrical testing is a critical phase. Each completed assembly undergoes a 100% functional test. This test verifies continuity across all circuits, checks for short circuits between adjacent terminals, and validates the integrity of the sealing. Connectors are tested for proper engagement force and retention.

Environmental validation tests are conducted on sample batches. These include thermal cycling, vibration testing, and immersion tests to confirm the IP67 rating. This rigorous process ensures that every unit bearing the OEM number DZ97189777020 will perform reliably for its intended service life in the field.

Installation of the DZ97189777020 junction box is a systematic process. First, disconnect the vehicle’s battery to ensure electrical safety. Locate and remove the old junction box assembly, which is typically mounted on a bracket behind the front bumper. Take note of the routing of the main harness connector and individual component wires.

Position the new assembly onto the mounting bracket and secure it with the provided or original fasteners. Ensure the mounting is firm to prevent excessive vibration. Reconnect the main vehicle harness connector to the new box, ensuring it clicks firmly into place. Then, reconnect all the individual component plugs (headlights, sensors, etc.) to their respective ports on the new box.

Before reassembling bumper covers, reconnect the battery and test all front-end electrical functions. Check headlights (high and low beam), turn signals, hazard lights, fog lights, and any parking sensors. Verify all functions operate correctly. This step confirms proper installation before finalizing the repair.

While the junction box is designed to be maintenance-free, periodic inspections are recommended during routine service. Visually inspect the box for any physical damage, cracks, or signs of moisture ingress inside the connectors. Ensure the main lid is securely closed and the sealing gasket is intact.

Check that all wire connectors are fully seated and locked. Look for any corrosion on the exposed metal parts of the connectors. Keep the area around the box clear of debris and mud buildup that could trap moisture against the seals. If fuses within the box need replacement, always use the correct amperage rating as specified in the vehicle manual.

The primary benefit of the DZ97189777020 assembly is enhanced electrical system reliability. By centralizing and protecting connections, it drastically reduces the incidence of electrical failures caused by loose, corroded, or damaged wires at the front of the truck. This leads to fewer roadside breakdowns and lower maintenance costs.

It significantly improves safety. Reliable front lighting is non-negotiable for safe night driving and signaling intentions to other road users. This junction box ensures that headlights and turn signals receive stable power, making the truck more visible and predictable in traffic.

For workshops and fleet mechanics, the serviceability advantage is major. Diagnosing a lighting fault becomes faster when all front circuits originate from one labeled, accessible box. Replacing the entire assembly is often quicker and more reliable than repairing multiple corroded individual wires.

The design also offers future-proofing. Many of these boxes include spare ports or circuits that can be used to add aftermarket lights or accessories neatly and professionally, without tapping into existing wires. This maintains electrical integrity when customizing trucks for specific roles.

In the long-haul trucking industry, the DZ97189777020 junction box is vital for vehicles covering hundreds of thousands of miles. It withstands constant vibration and exposure to different climates across continents, ensuring lights never fail due to a poor connection, which is critical for meeting delivery schedules and safety regulations.

Construction and mining sectors subject trucks to extreme punishment. Mud, rock chips, and frequent washing demand the IP67 protection this box provides. It keeps electrical systems running in environments where standard connections would quickly fail, supporting uninterrupted operation on job sites.

For refrigerated transport (reefer trucks), reliable electrical power extends beyond lights to include sensors and maybe auxiliary power units (APUs) at the front. A stable power distribution point helps ensure these temperature-management systems function without glitches.

Municipal and utility fleet vehicles, like garbage trucks or snow plows, often have added front-facing strobes, plow lights, or camera systems. The organized circuit capacity of this junction box makes integrating these additional devices cleaner and more reliable than makeshift wiring solutions.

The Shacman Front Bumper Junction Box Assembly DZ97189777020 is an indispensable component for maintaining the electrical heart of a truck’s front-end systems. Its design embodies a perfect balance of rugged environmental protection, logical electrical organization, and seamless OEM integration.

By choosing this genuine part, operators invest in safety, reliability, and reduced total cost of ownership. It prevents the cascading electrical problems that often stem from corroded or damaged bumper-area wiring. The assembly ensures that critical lighting and sensors function flawlessly, which is paramount for legal compliance and safe operation.

For fleet managers and owner-operators alike, specifying the correct OEM number DZ97189777020 guarantees a repair that restores the vehicle to its factory-designed condition. This commitment to quality components supports the legendary durability and dependability that Shacman trucks are known for worldwide, ensuring they stay on the road and productive.