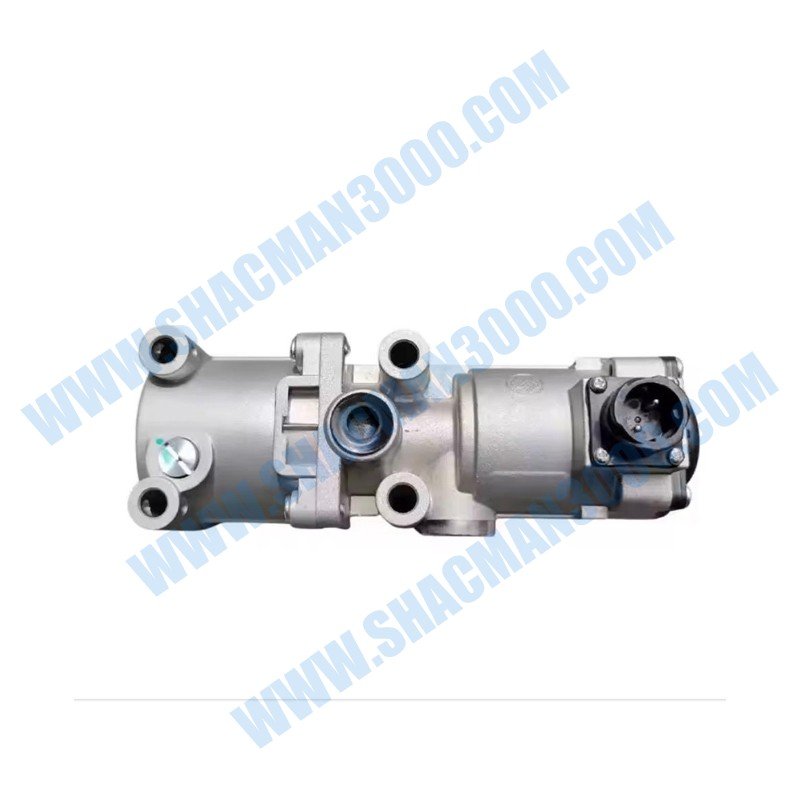

The Retarder Solenoid Valve FHB400 with OEM number HB400-60001 is a precision-engineered electro-hydraulic component specifically designed for Shacman truck retarder systems. This advanced solenoid valve plays a crucial role in controlling hydraulic pressure to the retarder system, ensuring smooth and reliable auxiliary braking performance. The HB400-60001 valve features rapid response times and precise flow control capabilities that enhance vehicle safety during downhill operations and heavy-load braking scenarios.

Manufactured to exacting standards, the HB400-60001 solenoid valve incorporates high-quality materials and advanced manufacturing techniques to withstand the demanding conditions of commercial truck operations. The valve’s robust construction ensures consistent performance under varying temperature conditions and hydraulic pressure fluctuations. This genuine Shacman component guarantees perfect compatibility with FHB400 retarder systems, providing truck owners with reliable braking assistance and enhanced driving safety in challenging road conditions.

| Paramètre | Valeur |

|---|---|

| Numéro OEM | HB400-60001 |

| Nom du produit | Retarder Solenoid Valve FHB400 |

| Marque | Shacman |

| Compatible Systems | FHB400 Retarder Systems |

| Voltage Rating | 24V DC |

| Current Consumption | 1.2A ±0.1A |

| Operating Pressure | Up to 25 Bar |

| Response Time | ≤ 50ms |

| Plage de température | -40°C to 120°C |

| IP Rating | IP67 |

| Connector Type | 2-pin Deutsch DT04-2P |

The Retarder Solenoid Valve FHB400 HB400-60001 incorporates multiple advanced features that ensure superior performance in demanding truck applications. The precision-engineered solenoid coil provides consistent magnetic force for reliable valve operation. The hardened steel valve components ensure long service life under high-pressure conditions. The integrated filter screen protects against contamination and ensures clean hydraulic fluid flow. These features collectively contribute to reliable retarder system operation and enhanced vehicle safety.

The advanced solenoid design ensures quick activation and deactivation responses. This rapid response capability provides precise control over retarder braking force. The optimized magnetic circuit minimizes energy consumption while maximizing performance. The fast reaction time enhances driver control during emergency braking situations. This technology contributes to smoother and more predictable braking performance.

The valve body is manufactured from high-strength aluminum alloy for excellent durability. All internal components are precision-machined to exact tolerances for reliable operation. The corrosion-resistant materials ensure long service life in harsh environmental conditions. The robust design withstands vibration and shock encountered in commercial vehicle applications. This construction quality ensures consistent performance throughout the component’s service life.

Utilizing genuine HB400-60001 Retarder Solenoid Valves provides numerous operational advantages for Shacman truck owners. The precise control over retarder operation enhances braking efficiency and reduces service brake wear. The reliable performance ensures consistent auxiliary braking power in various driving conditions. The extended service life reduces maintenance frequency and associated downtime costs. These benefits combine to deliver superior return on investment through improved safety and reduced operating expenses.

The reliable solenoid operation ensures consistent retarder performance during long descents. The precise control prevents brake fade that can occur with continuous service brake use. The predictable braking behavior enhances driver confidence in challenging road conditions. This safety feature is particularly important for heavily loaded vehicles operating in mountainous terrain. The improved braking control contributes to overall road safety.

The extended service life of the solenoid valve reduces replacement frequency and maintenance costs. The efficient operation minimizes wear on other braking system components. The reliable performance prevents unexpected failures that can lead to costly downtime. These factors contribute to lower total cost of ownership over the vehicle’s operational life. The economic benefits are measurable in reduced maintenance budgets and increased vehicle availability.

The Retarder Solenoid Valve FHB400 HB400-60001 is designed specifically for Shacman trucks equipped with FHB400 retarder systems in various demanding applications. This critical component is essential for long-haul transportation, construction operations, mining equipment, and heavy-duty commercial vehicles. The valve’s robust construction makes it suitable for both highway and severe off-road operating conditions. Its precise compatibility with FHB400 retarder systems ensures optimal performance across different load requirements. Whether for freight logistics or specialized transport, this solenoid valve delivers reliable performance.

In mountainous applications, the HB400-60001 valve ensures reliable retarder operation during extended descents. Its precise control maintains consistent braking force without overheating. The rapid response capability allows drivers to modulate braking power effectively. This reliability is crucial for vehicle safety on steep mountain roads. The valve contributes to reduced brake wear and improved control in challenging terrain.

For heavy load applications, the solenoid valve’s robust design handles increased hydraulic demands effectively. The consistent performance ensures reliable auxiliary braking under maximum load conditions. The durable construction withstands the additional stress from heavy braking requirements. This reliability is essential for transport operations with valuable or hazardous cargo. The valve supports safe operation and regulatory compliance.

Proper installation of the Retarder Solenoid Valve FHB400 HB400-60001 requires careful attention to technical procedures and specifications. Begin with a clean work environment and appropriate tools for the installation process. Disconnect the vehicle battery before beginning electrical work to prevent short circuits. Clean all hydraulic connections thoroughly to prevent contamination of the retarder system. Follow manufacturer torque specifications for all connections precisely. These procedures ensure optimal performance and prevent premature failure.

Verify proper voltage and polarity before connecting the electrical terminals. Use appropriate weatherproof connectors to ensure reliable electrical connections. Route wiring away from hot surfaces and moving components to prevent damage. Test electrical operation before finalizing the installation. These steps ensure reliable electrical performance and prevent system malfunctions.

Regular maintenance is essential for maximizing Retarder Solenoid Valve HB400-60001 performance and service life. Conduct visual inspections during routine service intervals for signs of leakage, corrosion, ou dégâts. Check electrical connections for proper tightness and corrosion protection. Monitor retarder system performance for any changes in operation that may indicate valve issues. Keep the valve clean from accumulated debris and corrosive materials. These practices help identify potential problems before they affect system performance.

Implement regular inspection schedules based on operating hours and service conditions. Conduct thorough retarder system examinations every 50,000 kilomètres. Include solenoid valve inspection in routine braking system maintenance procedures. Document all maintenance activities for reference and warranty purposes. These preventive measures extend component life and maintain optimal retarder performance.

Shacman maintains rigorous quality control standards for all Retarder Solenoid Valve HB400-60001 components. Each valve undergoes multiple inspection stages throughout the manufacturing process. Advanced testing procedures verify electrical characteristics, pressure performance, and response times. Environmental testing ensures reliable operation under extreme temperature and humidity conditions. The comprehensive traceability system tracks each component through production and distribution. This commitment to quality guarantees reliable performance in all applications.

State-of-the-art manufacturing facilities employ precision machining and automated assembly processes. Advanced quality control systems ensure consistent product quality and performance. Each solenoid valve undergoes functional testing under simulated operating conditions. The manufacturing process incorporates continuous improvement based on performance data and customer feedback. This excellence in production delivers components that exceed customer expectations.

The Retarder Solenoid Valve FHB400 with OEM number HB400-60001 represents the optimal choice for Shacman truck owners seeking reliable retarder system performance. The advanced engineering features and manufacturing quality ensure exceptional durability and precise control. The precision design guarantees perfect compatibility with FHB400 retarder systems. The performance benefits include enhanced braking safety, reduced operating costs, and extended service life. Investing in genuine Shacman components ensures compatibility and reliability for demanding transportation applications.

Proper installation and maintenance of the HB400-60001 solenoid valve are essential for maximizing its service life and performance. The quality assurance processes provide confidence in component reliability and safety. The versatile applications make it suitable for various industries and operating conditions. Choosing genuine Shacman retarder components protects your investment in commercial vehicle equipment. This commitment to quality supports efficient, sûr, and profitable transportation operations worldwide.