Dryer Upper Assembly

Сборка верхнего осушителя

Ensamblaje Superior del Secador

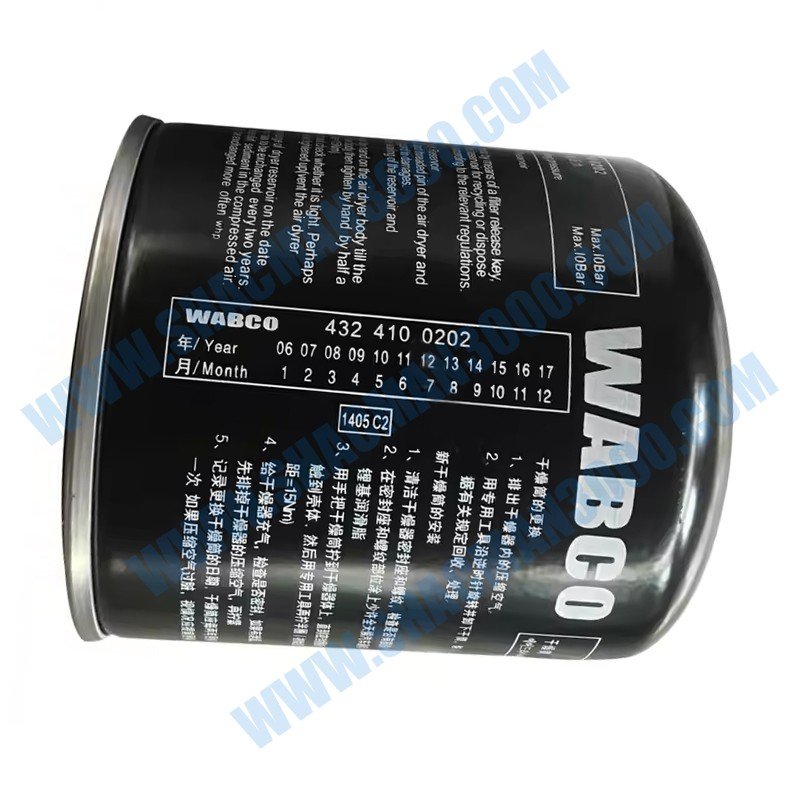

The Shacman Dryer Upper Assembly SAD-3588201 represents the pinnacle of air brake system technology for heavy-duty commercial vehicles. This critical component with OEM number SAD-3588201 ensures reliable air drying and system protection in the most demanding operating conditions.

Engineered specifically for Shacman truck models, this dryer upper assembly provides comprehensive moisture removal from compressed air systems, preventing freeze-ups and corrosion in brake system components. The advanced design guarantees optimal performance throughout extended service intervals.

With precision manufacturing and high-quality materials, the SAD-3588201 assembly delivers consistent air purification while withstanding the rigorous demands of commercial transportation. Its robust construction ensures long-term reliability and minimal maintenance requirements.

| Parameter | Specification |

|---|---|

| OEM Number | SAD-3588201 |

| Product Name | Dryer Upper Assembly |

| Brand | Shacman |

| Maximum Operating Pressure | 12 bar |

| Burst Pressure | 35 bar |

| Air Flow Capacity | 25 CFM |

| Dew Point | -40°C |

| Desiccant Type | Activated Alumina |

| Operating Temperature Range | -40°C to +85°C |

| Connection Size | 3/4″ NPT |

| Compatible Models | Shacman X3000, F3000, M3000 series |

Advanced activated alumina desiccant effectively removes moisture from compressed air, preventing water accumulation in brake systems and air-operated accessories.

Integrated purge valve system provides automatic desiccant regeneration, maintaining consistent drying performance without manual intervention or maintenance.

Multi-stage filtration system removes oil vapor and particulate contaminants from compressed air, protecting downstream components from contamination damage.

Dry, clean air delivery prevents freeze-ups and corrosion in brake system components, ensuring reliable braking performance in all weather conditions.

Effective moisture and contaminant removal significantly extends the service life of air system components, reducing maintenance costs and downtime.

Optimized air flow design minimizes pressure drop across the system, maintaining efficient operation of air-operated accessories and brake systems.

Heavy-duty aluminum housing with advanced coatings provides excellent corrosion resistance, ensuring long-term durability in harsh operating environments.

Robust construction withstands high operating pressures and pressure spikes, maintaining structural integrity and preventing system failures.

Engineered mounting system and internal components withstand heavy vibrations, preventing leaks and maintaining performance in commercial applications.

Advanced materials maintain consistent performance across extreme temperature ranges, from arctic cold to desert heat conditions.

The Shacman Dryer Upper Assembly SAD-3588201 is specifically engineered for heavy-duty commercial vehicles in the Shacman X3000, F3000, and M3000 series with air brake systems.

This critical component provides essential protection for vehicles operating in high-humidity regions, cold climates, or challenging environmental conditions where moisture control is crucial.

Ideal for long-haul transportation, construction, mining, and logging applications where reliable brake system performance and air system protection are essential for operational safety.

Requires installation by qualified technicians following manufacturer specifications for proper mounting, connection, and system integration.

Periodic inspection of mounting brackets, connections, and purge valve operation ensures optimal performance and early detection of potential issues.

Follow recommended service intervals for desiccant replacement and system inspection to maintain peak drying performance and system reliability.

Each Dryer Upper Assembly SAD-3588201 undergoes comprehensive quality control testing, including pressure integrity verification, flow performance testing, and leak detection.

Performance testing under simulated operating conditions ensures reliable air drying across various pressure ranges and environmental conditions encountered in commercial applications.

Environmental testing validates operation under extreme conditions, including temperature cycling, vibration exposure, and corrosion resistance assessment for long-term reliability.

Manufactured under certified quality management systems ensuring consistent product quality and performance standards across all production batches.

Comprehensive air flow and drying efficiency testing validates performance according to international standards for compressed air treatment.

Rigorous durability testing under simulated operating conditions ensures reliable performance throughout recommended service intervals.

Backed by comprehensive warranty coverage ensuring reliable performance and system protection in demanding commercial vehicle applications.

The Shacman Dryer Upper Assembly SAD-3588201 represents the highest standard in compressed air treatment technology for modern commercial vehicles. Engineered specifically for demanding operating conditions and extended service intervals.

Each unit undergoes multiple quality verification stages to ensure compliance with stringent requirements for drying efficiency, durability, and reliability in commercial transportation applications.

For specific technical specifications, installation guidelines, and compatibility verification for your Shacman vehicle, consult the official service documentation or authorized parts distribution channels.