Shacman Cummins Engine

Shacman Cummins Engine - Built for Efficient Transportation

Jointly developed by Shacman and Cummins, these engines are designed for long-distance logistics, heavy-duty transportation and special vehicles, covering the power range of 400-600HP, meeting the National VI/Euro VI emission standards, and combining high performance with low maintenance costs.

- Superior fuel economy: XPI high-pressure fuel injection technology is adopted, reducing the comprehensive fuel consumption by 15%-20% and helping the logistics fleet to save more than 100,000 yuan in annual fuel costs.

- Intelligent fault warning: ECU intelligent diagnostic system monitors the engine status in real time, warns of faults in advance, and reduces unexpected downtime.

- Long-life design: B10 has a life span of 1.2 million kilometers, and key components are strengthened to adapt to extreme environments such as plateau and high temperature.

- Environmental Compliance: The whole series supports National VI/Euro VI emission standard, equipped with DPF+SCR after-treatment system, fearless of environmental policy upgrade.

Shacman Cummins Engine Model Parameter Table

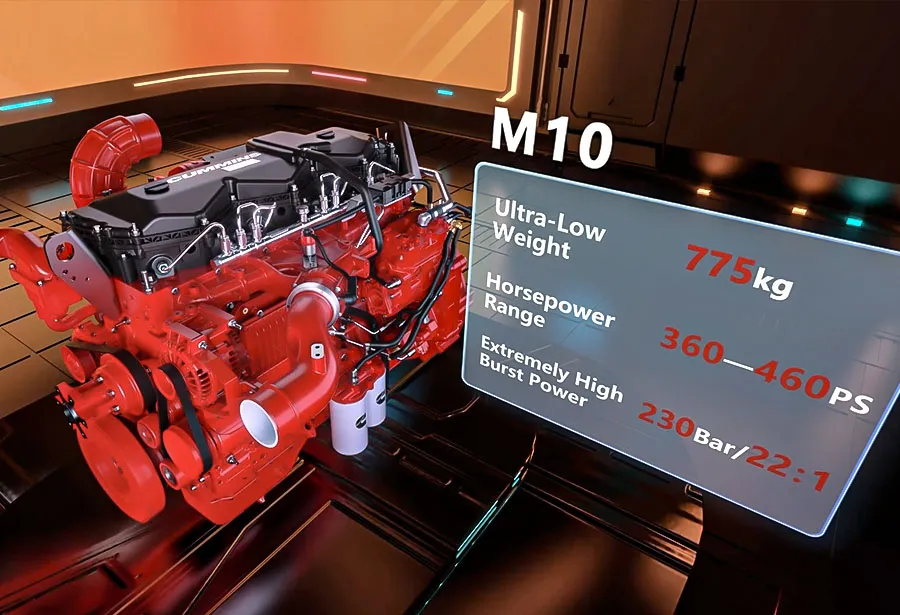

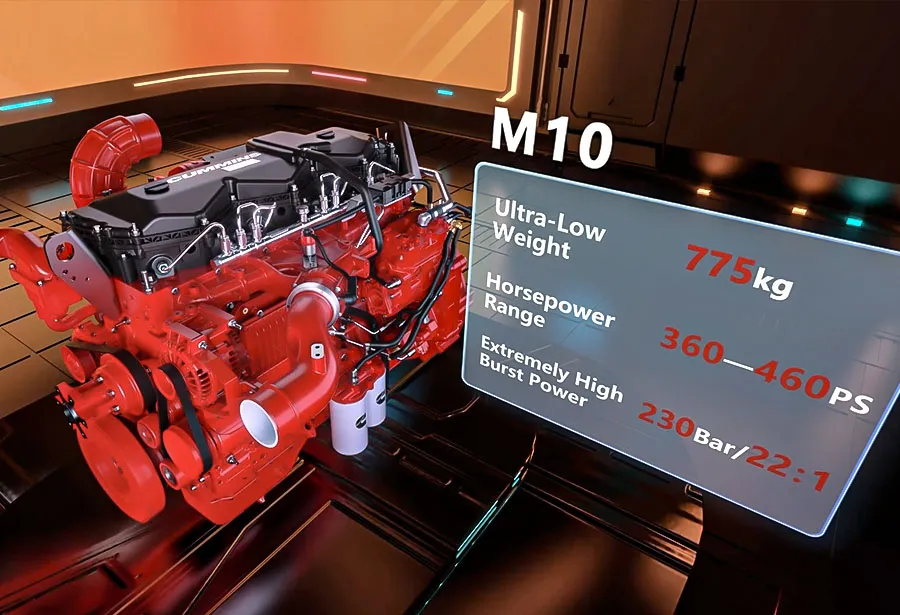

M10

| Power(PS) | 360-460 |

|---|---|

| Displacement(L) | 9.9 |

| Intake | Supercharged intercooler |

| Max torque(N·m) | 2200 |

| Rated rpm | 1900 |

| Emission | Euro Ⅲ、Euro Ⅴ |

| Application | H3000/H3000S/X3000/X5000 |

M13

| Power(PS) | 460-560 |

|---|---|

| Displacement(L) | 12.5 |

| Intake | Supercharged intercooler |

| Max torque(N·m) | 2600 |

| Rated rpm | 1800 |

| Emission | Euro Ⅲ、Euro Ⅴ |

| Application | F3000 / H6000 /X3000/ X5000 / X5000S / X6000 |

Features of Shacman Cummins Engine

-

Unmatched Performance

-

Fuel economy and power improvement

-

NVH improvement

-

Adaptability for Diverse Conditions

- Experience unmatched performance enhancements with the M13 and M10 series engines

- Fuel Economy: Enhanced by 5-8%, ensuring cost-efficiency and sustainability.

- Power Output: Boosted by 6%, delivering robust and reliable performance.

- NVH Performance: Improved by 7%, providing a smoother, quieter ride.

- Temperature Adaptability: Designed to operate efficiently in extreme conditions, from -40°C to 55°C.

- Discover the engineering excellence with the M13 and M10 series engines, setting new standards in fuel efficiency, power, and operational versatility.

Three core technologies

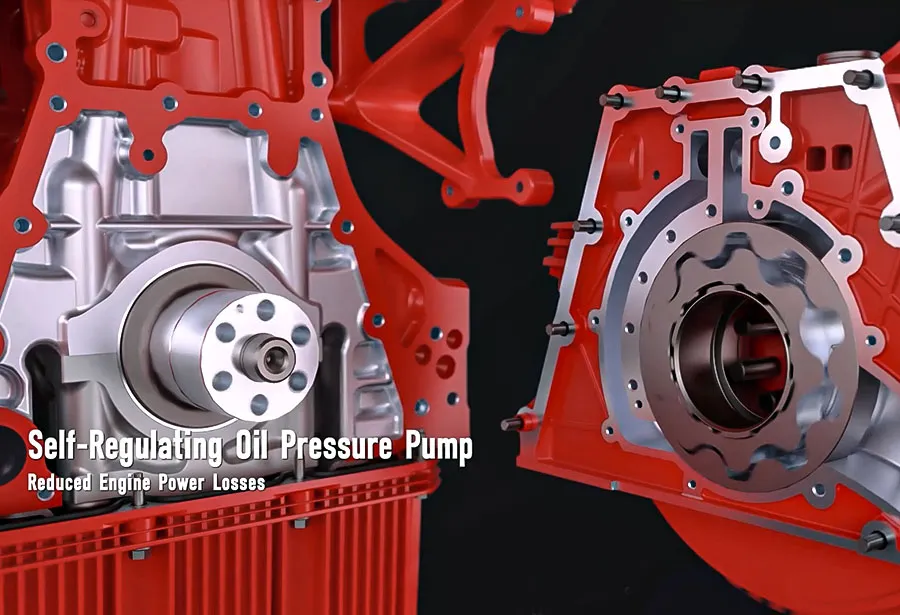

We have integrated three core hardware technologies to enhance our engine performance:

- Low Swirl Ratio Cylinder Head: Reduces air intake loss.

- High Injection Pressure Fuel System: Ensures efficient fuel delivery.

- High-Efficiency Turbocharger: Boosts overall engine performance.

Better economy with more power

Combined with our precise software collaboration, which optimally coordinates air, fuel, and timing control, we achieve complete and highly efficient combustion within the cylinder. This results in:

- Fuel Economy: Improved by over 5%, with a significantly wider economy range compared to main competitors.

- Low Speed Torque: Increased by 20% to 30%, delivering exceptional performance at lower speeds.

Enhanced Gear Train Design

Our helical gear train design, combined with gear shape optimization, significantly reduces both rattle and white noise, ensuring a quieter operation.

Innovative Structural Components

We employ a unique structural design featuring dual layers for the valve cover and oil pan, effectively minimizing noise radiation and enhancing overall acoustic performance.

Advanced Combustion Technology

To fundamentally control noise and vibration sources, we utilize Multiple Injection Combustion Technology. This approach ensures smoother and more gentle combustion within the cylinder, reducing noise and enhancing engine efficiency.

Optimized After-treatment Air Flow

By optimizing the air flow structure in the after-treatment system, we effectively reduce exhaust noise, contributing to a quieter and more pleasant driving experience.

Freezing Climate Adaptation

We have upgraded key sealing materials to withstand extreme cold conditions. Our optimized cooling system design, particularly for the cylinder head cooling passages, ensures engine reliability even in extremely high temperatures.

High Altitude Adaptation

The new generation turbocharger, with a speed limit increased by 20,000 rpm, is specifically designed for high-altitude applications, ensuring consistent performance.

Fuel Adaptation

Incorporating cutting-edge technologies such as nano filters and self-learning injectors, our engines are compatible with E0-E5 diesel and B35 bio-fuel, offering versatile fuel adaptation.

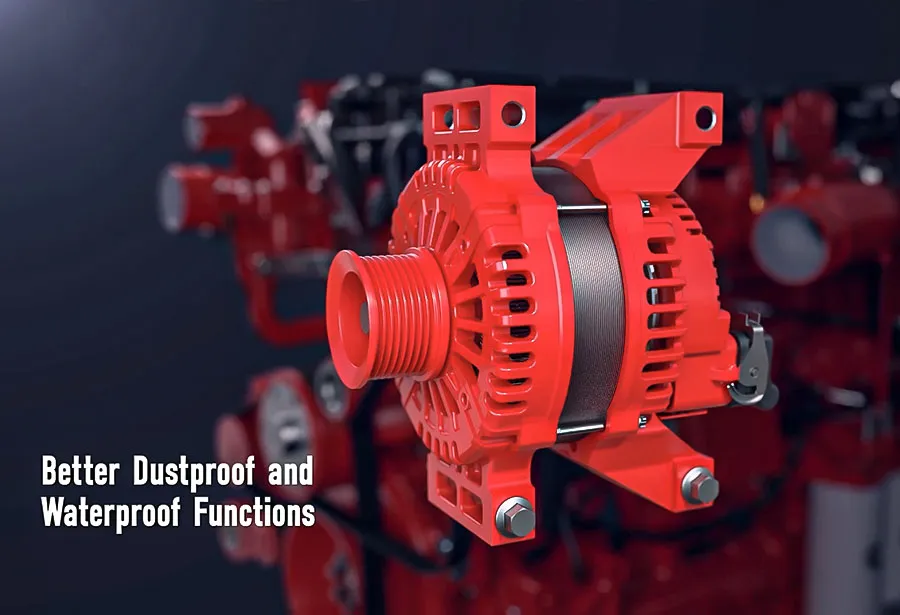

Rough Environment Adaptation

Utilizing top-grade sealing technology on external components like the generator and fan hub, we have significantly enhanced dust and water resistance, ensuring durability in harsh environments.

Engine Brake Adaptation

- Our new iBrake system design increases brake power by 28%, ensuring safer and more efficient operation, even in rugged and mountainous terrain.

- Experience the unmatched adaptability and performance of our engines, designed to excel in diverse and challenging conditions.

Application Models of Shacman Cummins Engine

- Long-distance logistics tractor

Examples of models: Shacman Delong X5000 (equipped with Cummins X12 engine); Shacman Delong X3000 (equipped with Cummins ISM11 engine);

Shacman Delong X3000 (equipped with Cummins ISM11 engine). - Construction Dump Trucks and Mining Trucks

Model examples: Shacman Delong X6000 8×4 dump truck (with Cummins M12 engine); Shacman Delong H6000 8×4 dump truck (with Cummins ISM11 engine);

Shacman Delong H6000 Mining Truck (equipped with Cummins X15 engine). - Special Vehicles and Special Purpose Vehicles (H3 Title)

Examples of vehicles: Shacman L5000 6×4 mixer truck (with Cummins B6.7 engine); Shacman M3000 4×4 mixer truck (with Cummins B6.7 engine); Shacman M3000 4×4 mixer truck (with Cummins B6.7 engine);

Shacman M3000 4×2 Tanker Truck (with Cummins L9 engine). - Models for Highland and Cold Regions

Model example: Shacman Delong X5000 plateau version (Cummins X12+turbocharging reinforcement). - Southeast Asia/right-hand drive market models

Example of model: Shacman Delong X3000 right-hand drive version (Cummins ISM11 + Tropical Cooling System).

Packaging of Shacman Cummins Engine

- Shacman cummins engines are securely packaged in high-quality, **customized wooden crates** designed to ensure maximum protection during transportation and storage. The sturdy wooden crates are made of durable, moisture-resistant plywood or solid wood and comply with international export standards (ISPM15 certified for heat-treated and pest-free materials).

- The engine is carefully secured inside the crate using heavy-duty steel mounts and shock-absorbing foam pads to prevent movement, impact, or wear and tear.

- The crate is reinforced internally with beams and edge protectors and externally with reinforced metal corners and steel straps to ensure structural integrity. Clear warning labels (e.g., “Fragile,” “Keep Dry”) and handling instructions are clearly visible. Each crate undergoes rigorous pre-shipment testing, including drop and vibration simulations, to ensure compliance with global logistics requirements.

Shipping Methods Of Shacman Cummins Engine

- Shacman cummins engines are transported globally via **Air Freight, Ocean Freight and Truck Freight** to meet a variety of logistical needs. For urgent deliveries, **Airfreight** ensures fast transportation (usually 3-7 days), with the engine safely packed in ISPM15 certified wooden packaging that meets international aviation safety standards. Critical components are cushioned with shock-absorbing materials to withstand handling during flight.

- For cost-effective bulk transportation, **maritime** is preferred. Engines are packed in watertight, ventilated containers (FCL or LCL option) and secured in reinforced wooden crates to prevent shifting during long voyages. Desiccant packages and anti-corrosion coatings protect against humidity and salt air. Compliance with maritime regulations and real-time container tracking ensure seamless port-to-port delivery.

- Regional or last mile distribution relies on **trucking** and engines are transported via heavy-duty trucks equipped with air suspension to minimize vibration. Crates are strapped to flatbeds using ISO-rated locks and routes are optimized for timely home delivery service. All methods include GPS monitoring, insurance coverage and customs documentation support to ensure flexibility, security and compliance with global supply chain requirements.