Key Points for “Engine Noise? Check These SHACMAN Parts”:

A thorough SHACMAN parts check is essential when your engine produces unusual noises. This guide helps you pinpoint issues from simple fixes to complex internal problems. Early detection through a systematic SHACMAN parts check can save time and costly repairs.

Noises from external parts are common. Begin your SHACMAN parts check here. These components are easier to inspect and fix. Use a mechanic’s stethoscope for precise identification. A proper inspection can isolate accessory-related sounds.

Check for bent blades or imbalance. A faulty clutch causes constant high-speed noise. Listen for unusual whirring during cold starts. This is a key point for cooling system health.

Worn bearings produce grinding or whining sounds. Use the stethoscope on each unit. Briefly remove belts to test. A SHACMAN parts check here prevents electrical and cooling failures.

Loose or damaged belts cause squealing. Inspect tension and wear. The crankshaft pulley may loosen. Regular SHACMAN parts check ensures drive system integrity.

Listen for high-pitched whistling from worn bearings. Check oil lines and balance. Attention to the turbo boosts performance and reduces noise.

Always begin with these external items. They are often the culprit. A detailed SHACMAN parts check list should include all accessories. This phase is vital for quick fixes.

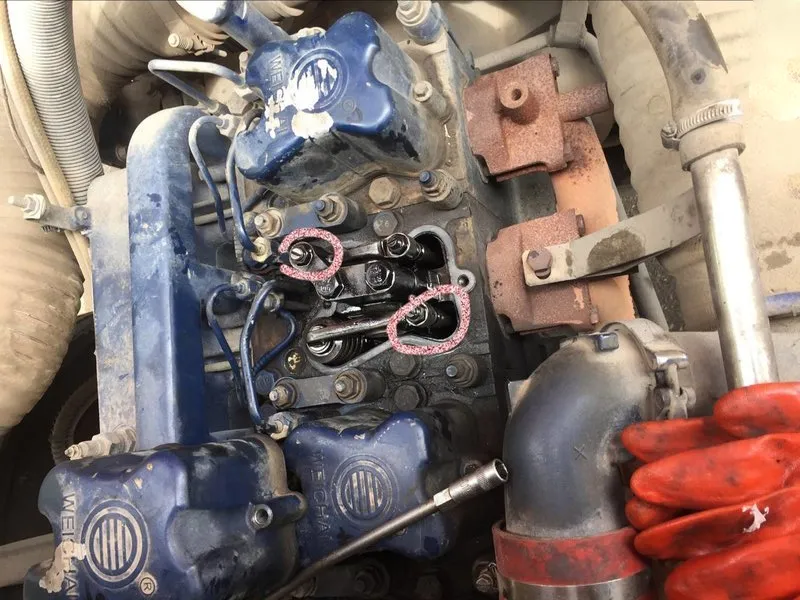

Valve train noises are rhythmic ticking sounds. They require a meticulous SHACMAN parts check. Adjusting valve clearance is a standard procedure. This ensures optimal engine breathing.

Excessive valve clearance causes distinct ticking. Use a feeler gauge to measure. Adjust according to SHACMAN manual. This restores quiet operation.

Faulty seals or broken springs affect compression. Listen for changes in sound. A compression test aids diagnosis. It’s a deeper level of troubleshooting.

Slack or wear creates slapping or rubbing noise. Check tensioner and sprockets. A thorough inspection here prevents catastrophic engine damage.

Valve adjustments need skill. Follow official SHACMAN service guidelines. This step is technical but essential for noise reduction.

Performing a SHACMAN parts check on the valve train is crucial. It maintains engine efficiency. A regular maintenance schedule includes valve inspections. This topic is covered in manuals.

Internal metal knocking sounds are serious. They demand an immediate SHACMAN parts check. These issues often require engine disassembly. A careful examination can diagnose piston, bearing, or injector faults.

Excessive clearance causes piston slap. It’s a hollow knocking sound during cold starts. Diagnosis involves measuring wear. This process is complex.

Worn bearings produce deep knocking under load. Oil pressure may drop. This requires engine oil analysis and teardown.

Low level or poor quality oil increases wear. Check oil grade and level routinely. This simple step prevents many internal noises.

Faulty injectors cause diesel knock and poor combustion. Use cylinder cut-off test. Injector inspection requires specialized tools.

Internal diagnosis is best left to professionals. However, understanding the signs helps. Proactive SHACMAN parts check can avoid severe damage. Always prioritize this if noises persist.

Hissing, popping, or roaring noises often stem here. A comprehensive SHACMAN parts check covers air filters, manifolds, and turbo. These systems impact engine performance directly. Attention here improves power and reduces noise.

Clogged filters restrict airflow, causing whistling. Inspect and replace regularly. This is simple but effective.

Leaking gaskets create ticking or hissing. Check for soot marks. Inspection on exhaust prevents power loss.

As part of intake/exhaust, turbo noise indicates damage. Listen for scraping or whining. Ensuring turbo longevity is important.

Faulty valves disrupt air-fuel ratio, causing knocking. Use diagnostic tools. This requires electronic scanning.

Conducting a review on these systems enhances efficiency. Air leaks are common noise sources. A diligent SHACMAN parts check routine includes all hoses and connections. This is mandatory for fleet owners.

A successful SHACMAN parts check follows methodical steps. Use proper tools and safety gear. Here are expert tips for your process. These make your diagnosis thorough and reliable.

OBD scanners and stethoscopes pinpoint issues. They are vital for diagnosis. Invest in quality tools for accurate results.

SHACMAN service manuals provide specifications. Follow them during any work. This ensures correct procedures for each task.

Prevent noise by regular intervals. Change oil, filters, and belts on time. A proactive approach avoids surprises.

If noise persists after basic checks, consult professionals. Avoid running a noisy engine. A final review by experts is wise.

Implementing these tips elevates your skills. A complete SHACMAN parts check covers all systems. Remember, it’s not just about noise; it’s about health. Your routine defines truck longevity.

Different noises indicate different problems. Here’s a quick reference for your diagnosis. Match the sound to the likely component. This guide speeds up the process.

Often valve train related. Perform an inspection on tappets and rockers. Adjust clearance as needed.

Could be piston or bearing issue. Internal inspection required. Immediate professional help is advised.

Check for air leaks in intake/exhaust. A review of hoses and gaskets solves this. Turbo inspection may be needed.

Often from accessory bearings. Focus on alternator, water pump. Belt inspection also helps.

Using this matrix, you can narrow down issues. Each noise type directs your efforts. A systematic SHACMAN parts check saves diagnostic time. Practice makes you proficient.

Routine checks offer multiple advantages. They extend engine life, improve fuel economy, and ensure safety. A disciplined program reduces downtime. Let’s explore the benefits of consistency.

Investing time in a SHACMAN parts check pays off. It’s a proactive approach to truck care. Every check you perform adds value. Make it a habit for fleet excellence.

For truck owners, a basic review is doable. Follow these steps for a preliminary assessment. This routine helps identify obvious issues. Always prioritize safety during any work.

After this basic process, you’ll have a clearer picture. If problems remain, seek advanced SHACMAN parts check services. Remember, a thorough inspection is layered. Start simple, then deepen as needed.

Engine noise in SHACMAN trucks is manageable with a systematic **SHACMAN parts check**. From external attachments to internal components, each part plays a role. Regular inspection prevents minor issues from escalating. Embrace the discipline for optimal truck health.

We’ve covered extensive ground in this guide. The key is to act promptly upon hearing unusual sounds. A diligent routine is your best defense. For more detailed insights and professional support, learn more about SHACMAN maintenance and parts. Your journey to a quieter engine begins with a committed SHACMAN parts check today.

Remember, a successful SHACMAN parts check combines knowledge, tools, and timing. Keep your SHACMAN truck running smoothly with regular intervals. This comprehensive article aims to empower you. May your efforts always yield positive results.