Proper SHACMAN Parts Maintenance is the cornerstone of fleet reliability and cost management. Following a disciplined schedule prevents unexpected breakdowns.

This guide provides a comprehensive, model-aware maintenance table for all major SHACMAN truck components, from engine fluids to chassis systems.

SHACMAN Parts Maintenance – Essential for fleet reliability.

SHACMAN trucks, known for their ruggedness and reliability, serve in diverse roles globally. Their durability is maximized only with proper care. Effective SHACMAN Parts Maintenance is not optional; it’s a strategic investment.

This maintenance schedule is synthesized from official SHACMAN manuals and real-world service data. Intervals vary based on truck model (tractor, dump truck, cargo truck), operating conditions, and engine systems (Weichai WP series, Cummins ISM, etc.).

Adhering to a structured SHACMAN Parts Maintenance plan ensures your assets deliver maximum uptime and return on investment. Neglect leads to accelerated wear and costly repairs.

Maintenance frequency is affected by: Load Weight, Driving Terrain, Climate, Fuel Quality, and Driver Habits. Severe service conditions necessitate shorter intervals.

Regular fluid and filter changes are the lifeblood of your SHACMAN truck. Contaminated oil or clogged filters cause immediate and severe engine damage.

| Part / Item | Recommended Interval | Notes & Tips |

|---|---|---|

| Engine Oil & Filter | 16,000 – 32,000 km (10k – 20k mi) | Interval depends on engine model. Use only approved CH-4 or higher grade oil. |

| Fuel Filter | Every 16,000 km (10,000 mi) | Critical for protecting fuel injectors. Change more often with poor-quality fuel. |

| Engine Coolant (Antifreeze) | Every 2 Years | Flush the system completely before refill. Maintain correct concentration. |

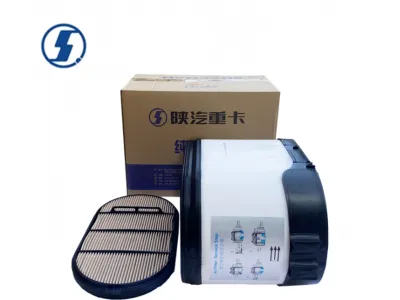

| Air Filter Element | Inspect every 16k – 32k km | Replace immediately if dirty. In dusty environments, clean every 8,000 km. |

| Transmission Oil | 40,000 – 80,000 km (or 2-4 years) | Follow specific manual for transmission type (manual or AMT). |

Filters are inexpensive barriers against costly damage. A failed air filter allows abrasive dust into the engine cylinders, causing rapid wear.

A clogged fuel filter strains the fuel pump and can lead to power loss. Regular changes are a core part of smart SHACMAN Parts Maintenance.

The chassis endures tremendous stress. Proper lubrication and inspection are non-negotiable for safety and component life.

Intervals differ drastically by vehicle application. Post-initial fill, follow these strict SHACMAN Parts Maintenance rules:

Brake Fluid: Hygroscopic (absorbs water). Replace every 2 years to prevent brake system corrosion and maintain boiling point.

Suspension System: Conduct a thorough annual inspection. Check leaf springs, shock absorbers, and U-bolts for cracks, wear, or looseness.

This proactive SHACMAN Parts Maintenance check ensures stability and ride quality, preventing major failures.

Electrical failures strand trucks. Regular checks are simple but vital.

Monthly Check: Inspect terminals for corrosion (green/white powder). Clean with baking soda solution. Check voltage; below 12.4V requires charging.

Ensure connections are tight to prevent starting issues.

Check every 8,000 km (5,000 mi): For diesel engines, inspect glow plug performance. Poor glow plugs cause hard cold starts and excessive white smoke.

Weekly Pressure Check: Use a calibrated gauge. Incorrect pressure causes uneven wear and blowouts.

Inspect tread depth and sidewalls for cuts/bulges. Never repair sidewall damage.

Integrating these checks into your standard SHACMAN Parts Maintenance routine prevents 80% of roadside electrical and tire-related failures.

New SHACMAN truck owners MUST complete the first compulsory maintenance at the specified mileage/time. This service is often free (parts and labor).

Skipping it voids certain warranty benefits. Always get it stamped in your service book at an authorized center.

For export vehicles, typical warranty is 24 months or 100,000 km for engine/transmission. Specific components have different coverages.

Condition: Warranty is valid ONLY if scheduled SHACMAN Parts Maintenance is performed using genuine or approved parts and documented.

Critical Warning: Using counterfeit or substandard filters, oils, or parts can cause catastrophic engine failure.

Such failures are not covered under warranty. Always source parts from authorized SHACMAN dealers or certified distributors to guarantee quality and protect your investment. This is the most important rule in SHACMAN Parts Maintenance.

Consistency is key. Print this schedule, integrate it into your fleet management software, and never miss a service.

Always check your specific vehicle manual for final authority.

Keep detailed records of all maintenance work performed.

Insist on authentic SHACMAN parts for every replacement.

A disciplined approach to SHACMAN Parts Maintenance is the surest path to minimizing downtime, maximizing safety, and achieving the lowest total cost of ownership for your SHACMAN truck fleet.