Oil Seal Balancer

Масляный сальник балансира

Sello de Aceite del Balanceador

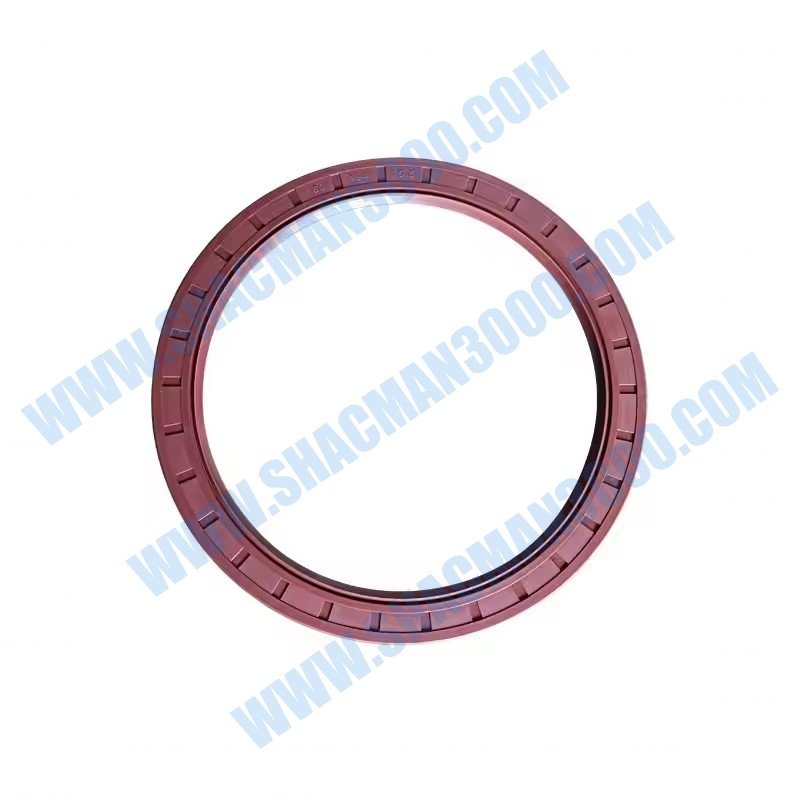

The genuine Shacman Oil Seal Balancer with OEM number DZ91259520512 delivers exceptional sealing performance for engine balancer shaft applications. This critical sealing component ensures proper lubrication containment and prevents oil leaks in demanding operating conditions.

Manufactured to exact OEM specifications using premium materials, the DZ91259520512 oil seal provides reliable performance and extended service life. The precision engineering guarantees perfect fitment and optimal sealing for Shacman engine systems requiring balancer shaft protection.

With advanced lip design and high-quality elastomer compounds, this oil seal offers superior resistance to wear, heat, and chemical degradation. Regular maintenance with genuine components ensures proper engine lubrication and prevents costly oil leakage issues.

| Parameter | Specification |

|---|---|

| OEM Part Number | DZ91259520512 |

| Product Name | Oil Seal Balancer |

| Brand | Shacman |

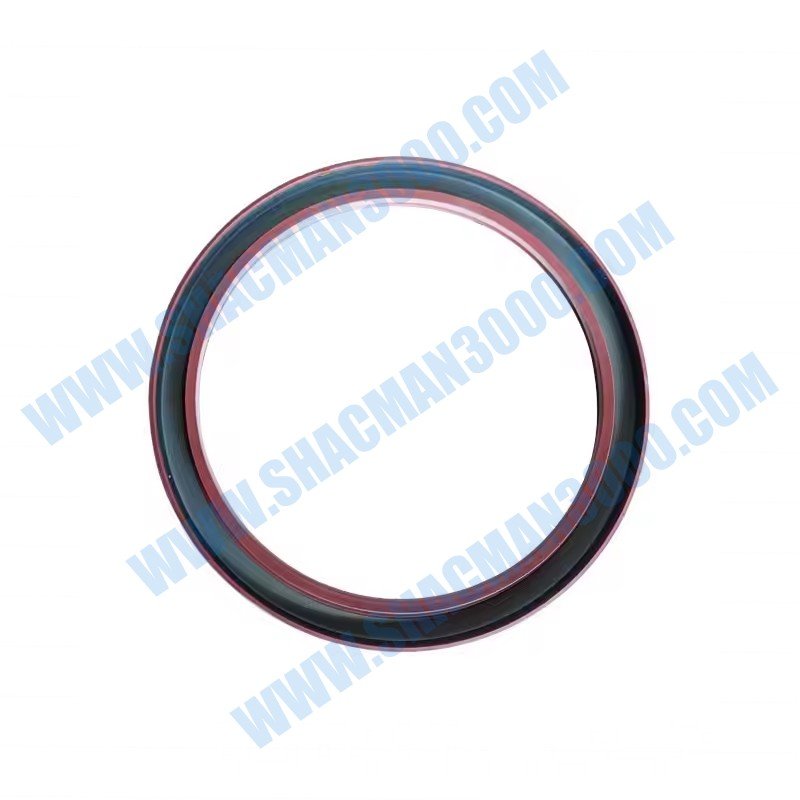

| Material | Nitrile Rubber with Steel Case |

| Operating Temperature | -40°C to +120°C |

| Shaft Diameter | Standard OEM Specifications |

| Lip Design | Single Lip with Garter Spring |

| Compatibility | Shacman Engine Balancer Systems |

The Shacman Oil Seal Balancer provides exceptional sealing capabilities for balancer shaft applications. This critical component prevents oil leakage and ensures proper lubrication system integrity.

Precision engineering ensures consistent contact pressure and optimal lip engagement. The design maintains effective sealing throughout the component’s service life under various operating conditions.

Manufactured from high-quality nitrile rubber compounds, this oil seal offers excellent resistance to wear and mechanical stress. The robust construction withstands continuous operation in engine environments.

Advanced material formulations provide superior resistance to heat aging and chemical degradation. The steel case ensures dimensional stability and proper installation retention.

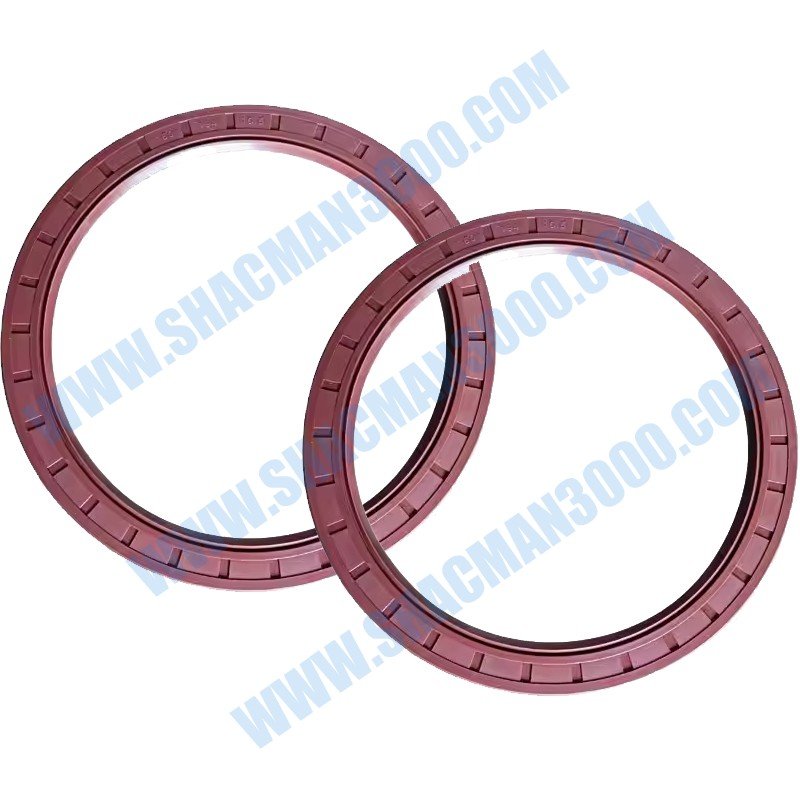

Each DZ91259520512 oil seal undergoes rigorous quality control procedures throughout manufacturing. Precise dimensional accuracy guarantees perfect fitment without modifications.

Computer-aided design and manufacturing processes ensure consistent product quality and performance. Engineering specifications meet original equipment requirements for reliability.

This genuine Shacman component is specifically engineered for engine balancer shaft applications in heavy-duty trucks. The oil seal ensures optimal performance across various engine configurations.

Proper installation maintains factory specifications for sealing performance and lubrication containment. Vehicle operators can expect reliable sealing performance and prevention of oil leaks.

The Oil Seal Balancer performs reliably in demanding engine environments with high temperatures and rotational speeds. From cold starts to continuous operation, this component maintains sealing integrity.

The design accounts for thermal expansion, shaft eccentricity, and varying lubrication conditions. Heavy-duty transportation and construction applications benefit from this durable sealing component.

Shacman implements stringent quality control measures throughout the entire production process. Each oil seal undergoes multiple inspection stages before packaging.

Advanced testing equipment verifies dimensional accuracy, material properties, and sealing performance. The manufacturing facility maintains ISO certification for quality management systems.

Comprehensive laboratory testing simulates real-world operating conditions to ensure reliability. Durability testing exceeds standard requirements for long-term performance.

Sealing efficiency tests verify performance under various pressure and temperature conditions. The results confirm the product’s capability in demanding engine applications.

Proper installation requires careful handling and correct installation tools for optimal results. Technicians should follow manufacturer-recommended procedures during assembly.

Shaft surfaces must be clean and free from damage before installation. Professional installation ensures proper seating and prevents premature seal failure.

Regular visual inspections during routine maintenance help identify potential issues early. Check for signs of oil leakage or seal deterioration during service intervals.

Proper lubrication system maintenance extends seal service life. Replacement is recommended when inspection reveals leakage or seal damage.

The optimized design ensures effective oil containment for reliable engine lubrication. Properly functioning oil seals prevent lubrication loss and related engine damage.

The component’s sealing efficiency contributes to stable oil pressure and lubrication. This protects sensitive engine components and extends overall engine lifespan.

Maintaining proper lubrication directly impacts engine efficiency and performance. Effective sealing systems reduce oil consumption and operating costs.

The precise engineering minimizes friction and wear on sealing surfaces. This contributes to overall vehicle efficiency and reduced maintenance requirements.

Shacman stands behind the quality of every genuine component manufactured. The Oil Seal Balancer comes with comprehensive warranty coverage.

This commitment reflects the manufacturer’s confidence in product reliability and durability. Customers receive full support for any manufacturing defects.

Professional technical assistance remains available for installation guidance and troubleshooting needs. Shacman’s network provides expert support when required.

Comprehensive documentation accompanies each product for reference and guidance. Customers can access additional resources through authorized service centers.

Regular inspection during scheduled maintenance helps identify wear before failure occurs. Visual checks should include seal condition and leakage assessment.

Replacement timing depends on operating conditions and oil quality factors. Severe service applications may require more frequent inspection intervals.

Professional installation by qualified technicians ensures optimal performance and system integrity. Certified workshops have proper tools for correct installation.

Proper seal orientation and installation depth are essential during replacement. This ensures the sealing system functions as designed by the manufacturer.

All raw materials undergo rigorous certification processes before production begins. Rubber compounds meet automotive standards for sealing applications.

Steel cases and spring components are tested for corrosion resistance and durability. Material traceability ensures consistent quality across production batches.

State-of-the-art manufacturing equipment ensures precision and consistency in production. Automated processes maintain tight tolerances and dimensional accuracy.

Each production stage includes quality checks and verification procedures. Final inspection confirms all specifications are met before packaging and shipping.

Ideal for long-haul trucks operating under continuous heavy loads in varying conditions. The oil seal provides reliable sealing for engines in demanding transportation.

The component maintains sealing integrity during extended highway operation. Fleet operators benefit from consistent performance across different operating conditions.

Essential for equipment operating in demanding environments where sealing reliability is critical. The robust design handles challenging operating conditions.

Mining applications benefit from the component’s resistance to contamination and harsh environments. The durable construction ensures reliable performance.

Proper sealing system maintenance with genuine components significantly extends engine operational lifespan. Effective oil containment prevents lubrication-related damage.

The oil seal’s durable construction contributes to overall engine reliability and longevity. This translates to extended service life and improved return on investment.

Maintaining proper lubrication ensures consistent engine performance and efficiency. Effective sealing reduces oil consumption and environmental contamination.

The component’s precision engineering ensures reliable performance throughout its service life. Vehicle operators experience consistent engine operation.

Genuine Shacman components provide optimal protection that reduces long-term maintenance costs. Preventing oil leakage damage offers significant economic benefits.

The initial investment in quality sealing parts pays dividends through extended service intervals. Fleet managers appreciate the predictable maintenance costs.

Reliable sealing components contribute to overall vehicle uptime and operational efficiency. This ensures business continuity for commercial operators.

The proven performance of genuine Shacman parts provides confidence in vehicle reliability. Operators can depend on consistent sealing system performance.

Always verify part number DZ91259520512 before purchase to ensure compatibility with your specific engine balancer system requirements.

Genuine Shacman parts meet exact engineering specifications and performance requirements for optimal engine protection and sealing efficiency.

Professional installation and regular maintenance inspections are essential for achieving optimal performance and ensuring sealing system integrity is maintained.