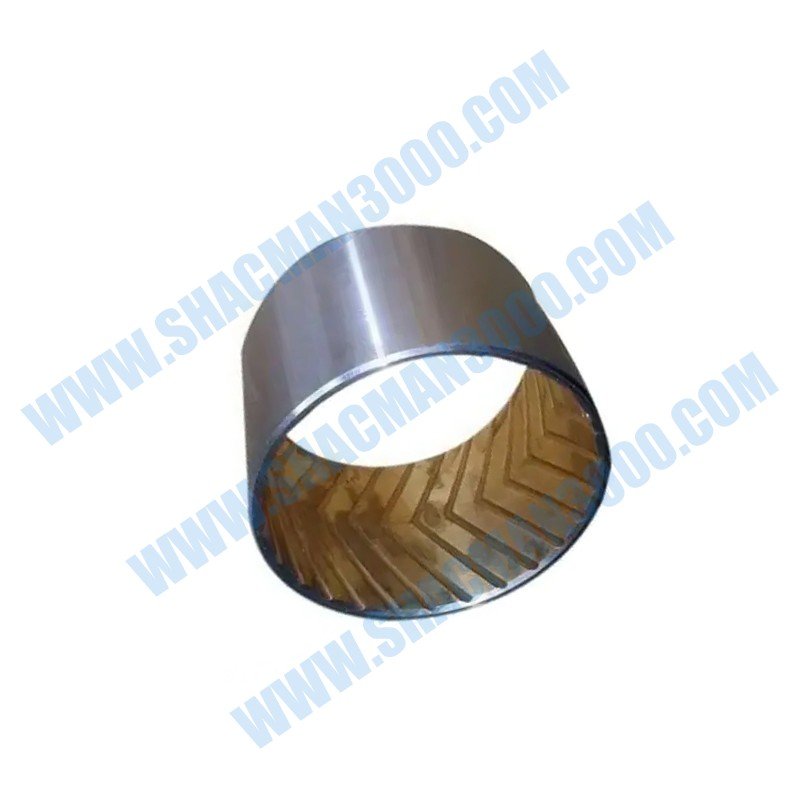

Bogi Bush Inner Seal

Внутреннее уплотнение втулки Bogi

Sello Interior del Buje Bogi

The Shacman Bogi Bush Inner Seal with OEM number 16018510.51 represents the pinnacle of internal sealing technology for heavy-duty truck suspension systems. This precision-engineered component provides exceptional internal protection for bogie systems, ensuring optimal performance and longevity. The 16018510.51 seal is specifically designed to withstand extreme internal pressures and mechanical stresses encountered in commercial transportation applications.

Manufactured to exact OEM specifications, this bogi bush inner seal guarantees perfect compatibility with Shacman truck models and ensures reliable operation under the most demanding conditions. Its advanced design incorporates multiple sealing mechanisms that work in harmony to prevent internal lubricant leakage and contamination ingress. The robust construction maintains dimensional stability throughout extended service periods.

With its specialized material composition and precision engineering, the 16018510.51 inner seal delivers superior internal sealing performance. The high-quality rubber compound maintains excellent flexibility across wide temperature ranges while resisting degradation from internal pressures and mechanical stresses. This results in extended service life and reduced maintenance requirements.

| Parameter | Specification |

|---|---|

| OEM Number | 16018510.51 |

| Product Name | Bogi Bush Inner Seal |

| Brand | Shacman |

| Material Composition | High-Grade Nitrile Rubber with Steel Core |

| Outer Diameter | 185 mm ± 0.4 mm |

| Inner Diameter | 140 mm ± 0.3 mm |

| Width/Thickness | 15.5 mm ± 0.2 mm |

| Operating Temperature Range | -40°C to 125°C |

| Pressure Resistance | Up to 18 Bar |

| Rotation Speed Capacity | Maximum 12 m/s |

| Compatible Models | Shacman F3000, M3000, X3000 Series |

| Service Life | Minimum 120,000 km |

The Shacman 16018510.51 Bogi Bush Inner Seal incorporates revolutionary internal sealing technology that sets new industry standards. Its multi-layered sealing design provides comprehensive internal protection against lubricant leakage and contaminant infiltration. The precision-engineered internal sealing lips ensure consistent performance throughout the product’s operational lifespan.

Advanced spring-loaded technology maintains uniform internal pressure across varying operational conditions. This innovative feature automatically compensates for natural wear and thermal variations, ensuring reliable internal sealing performance. The reinforced steel core provides exceptional structural integrity while preventing deformation under extreme internal pressures.

Specialized internal surface treatments enhance the seal’s resistance to abrasion and chemical degradation from within. These advanced treatments create a protective barrier that extends service life in challenging internal environments. The optimized internal geometry minimizes friction while maximizing sealing efficiency and performance reliability.

The 16018510.51 inner seal delivers exceptional internal sealing performance through its sophisticated lip configuration. Multiple internal sealing lips work synergistically to create an effective barrier system. This advanced design prevents lubricant escape and internal contamination simultaneously.

Precision manufacturing ensures consistent internal lip geometry and surface finish across production batches. This manufacturing consistency translates to reliable performance and predictable service life. The specialized rubber formulation maintains optimal elasticity across the entire operating temperature spectrum.

The Shacman Bogi Bush Inner Seal offers significant performance advantages for commercial vehicle maintenance. Its zero-leak internal design ensures complete lubricant containment within the bogie system. This maintains optimal internal suspension performance and substantially reduces maintenance frequency.

Exceptional internal temperature resistance allows reliable operation in extreme climate conditions. The seal performs consistently from freezing cold to extreme heat environments. This thermal stability ensures dependable performance across diverse geographical operating regions.

User-friendly installation features include clear internal orientation markings and precision dimensions. These design elements significantly reduce installation time and prevent assembly errors. The internal contamination protection capability extends component life and improves vehicle reliability.

Internal durability is fundamental to the 16018510.51 Bogi Bush Inner Seal design. High-strength internal materials withstand extreme pressure and mechanical stress in commercial transportation. Robust internal construction ensures structural integrity under demanding operating conditions.

Internal wear-resistant properties protect against mechanical damage and material degradation. The advanced internal material formulation extends service life significantly in harsh operating environments. These durability features reduce replacement frequency and lower operational costs substantially.

Proper installation of the 16018510.51 Bogi Bush Inner Seal requires meticulous attention to technical procedures. Begin by thoroughly cleaning all internal contact surfaces to remove debris and old sealing materials. Inspect internal sealing surfaces for any imperfections affecting performance.

Lubricate the internal seal lip with clean, compatible grease before installation to prevent initial dry operation. Use specialized tools designed specifically for internal seal installation to ensure even pressure distribution. Avoid instruments that could damage internal sealing surfaces.

Verify proper internal orientation and seating depth after installation to ensure optimal performance. Check for uniform internal contact and absence of distortion in the installed position. Test internal bogie system operation and inspect for leaks before vehicle service return.

Follow manufacturer internal specifications precisely during installation for optimal results. Ensure the internal sealing environment is clean and free from particulate contamination. Use manufacturer-recommended internal lubricants to prevent material incompatibility issues.

Apply uniform internal pressure during installation to prevent distortion or damage to seal structure. Verify correct internal alignment with related components before final assembly. These practices ensure maximum internal sealing efficiency and extended service life.

Each 16018510.51 Bogi Bush Inner Seal undergoes comprehensive internal quality control throughout manufacturing. Multiple internal inspection stages ensure consistent product excellence and performance reliability. Internal pressure testing verifies structural integrity under operational conditions.

Internal material testing confirms chemical resistance and mechanical strength符合 industry standards. Dimensional accuracy testing guarantees perfect internal fitment with Shacman truck models. These rigorous internal procedures ensure every seal meets exacting quality benchmarks.

Internal leak testing assesses sealing effectiveness and lubricant containment under simulated conditions. Internal endurance testing evaluates performance over extended periods and stress cycles. The product maintains internal reliability through demanding service periods.

Internal manufacturing processes comply with international quality standards and automotive specifications. Products meet automotive industry requirements for internal safety and performance. Regular internal audits maintain adherence to regulatory standards.

Internal quality management systems guide precision production practices and minimize variations. Environmental testing validates internal performance across temperature extremes. This commitment ensures consistent internal quality for customers worldwide.

The 16018510.51 Bogi Bush Inner Seal serves various Shacman heavy-duty truck applications requiring internal protection. It functions as a critical internal component in multi-axle bogie systems and suspension linkages. The seal provides essential internal contaminant exclusion and lubricant retention.

Internal compatibility extends across different Shacman truck configurations including updated series. This universal internal application ensures comprehensive coverage for commercial vehicle fleets. The design supports both original equipment and replacement market requirements.

Ideal for demanding internal applications in transportation and construction industries. The product performs effectively in both standard and severe operating environments. Always verify specific internal vehicle compatibility before installation procedures.

Specifically engineered for seamless internal integration with Shacman truck bogie systems. Direct internal replacement capability simplifies maintenance and reduces downtime. Precision internal engineering maintains proper sealing alignment.

The seal connects perfectly with existing internal bogie components and elements. Internal design features complement vehicle performance and safety standards. These integration advantages make it ideal for fleet maintenance programs.

Regular internal inspection of Bogi Bush Inner Seals is essential for vehicle safety. Schedule comprehensive internal checks during routine maintenance intervals. Monitor internal seal condition and lubricant levels during service.

Look for internal wear signs or degradation affecting system performance. Replace internal bogi bush seals according to established service schedules. Using genuine Shacman parts ensures perfect internal compatibility.

Inspect internal sealing surfaces and related components during maintenance. Check internal lubricant condition and contamination levels. Address any internal issues promptly to prevent operational failures.

Establish consistent internal inspection schedules based on operating conditions. For severe service, consider more frequent internal inspection intervals. Document internal maintenance activities for future reference.

Monitor internal vehicle handling and suspension performance for detection. Train personnel in proper internal inspection techniques. These strategies maximize internal component life and prevent failures.

The 16018510.51 Bogi Bush Inner Seal demonstrates excellent internal performance across conditions. Its internal design accommodates vehicle vibration and movement. The seal maintains stable internal performance during operations.

Internal thermal-resistant materials ensure reliable operation in climates. The component performs consistently under temperature variations. These internal capabilities suit international transportation operations.

Internal vibration damping properties minimize stress and ensure function. The assembly withstands continuous internal use without degradation. Comprehensive testing validates internal real-world performance.

Advanced internal material formulation prevents degradation from exposure. The seals maintain internal performance through challenging conditions. Weather-resistant internal construction protects against elements.

This internal environmental adaptability ensures reliable performance. The product meets commercial vehicle internal requirements. These internal features provide operator confidence and reliability.

In summary, the Shacman 16018510.51 Bogi Bush Inner Seal represents excellence in internal sealing technology. Its precision internal engineering and robust construction make it essential for bogie system integrity. With comprehensive internal quality assurance, this product delivers exceptional value for commercial vehicle operators.

By choosing genuine Shacman internal components, you invest in vehicle reliability and operational efficiency. The 16018510.51 internal seal provides the protection needed for demanding applications. Explore the advantages of this premium internal sealing solution for your maintenance requirements.