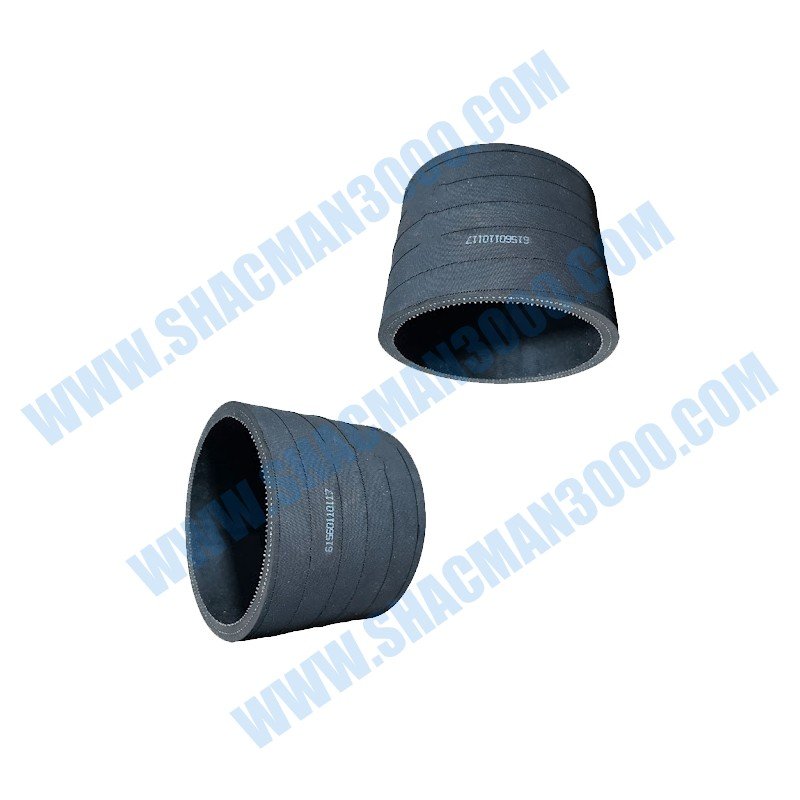

Compressor Intake Assembly

Узел впуска компрессора

Conjunto de Admisión del Compresor

The Shacman Compressor Intake Assembly BY1001012885 is a vital air supply system component responsible for delivering clean, filtered air to the vehicle’s air brake compressor. This genuine OEM assembly, precisely identified by part number BY1001012885, ensures optimal compressor efficiency, longevity, and the reliable production of compressed air for braking and auxiliary systems. A compromised intake can lead to compressor wear, reduced braking power, and increased maintenance costs. For Shacman trucks operating in dusty or demanding environments, maintaining a clean and unrestricted air path to the compressor is critical for overall vehicle safety and operational reliability. This assembly integrates filtering and connecting components to protect the compressor’s internal mechanisms from abrasive contaminants.

Designed for durability and consistent performance, it features robust construction and precise fitment for specific Shacman chassis models. Using the authentic part guarantees the correct airflow characteristics and filtration efficiency, safeguarding your air brake system’s integrity and ensuring consistent, reliable braking force when you need it most.

| Parameter | Specification / Value |

|---|---|

| OEM Part Number | BY1001012885 |

| Product Name | Compressor Intake Assembly |

| Brand | Shacman |

| Compatible Vehicle Models | Shacman F3000, X3000, M3000 Series (Specific Configurations) |

| Primary Function | Filter and Deliver Air to the Air Brake Compressor |

| Included Components | Intake Hose, Connectors, Brackets, Pre-Filter/Cyclone Assembly |

| Hose Material | Reinforced Rubber or Synthetic Polymer |

| Connection Type | Clamp-on or Quick-Connect Fittings |

| Operating Temperature Range | -40°C to +120°C |

The air compressor is the heart of the truck’s brake system. It pumps air into the reservoirs that supply the brake chambers. The intake assembly is its lungs.

Its primary role is to supply a consistent volume of clean, dry air to the compressor inlet. It often includes a pre-filter or cyclone separator to remove bulk dust and moisture.

Clean air is non-negotiable for compressor health. Abrasive particles like dust and soot can act like sandpaper on the compressor’s cylinders, pistons, and valves.

This wear leads to reduced compression efficiency, increased oil consumption (in oil-lubricated compressors), and ultimately, compressor failure. A failed compressor means no air brakes.

A restricted or leaking intake assembly forces the compressor to work harder. It may cycle more frequently to maintain system pressure, increasing fuel consumption and wear.

Moisture ingress is another critical concern. The assembly helps minimize the amount of water vapor drawn into the compressor, protecting the air dryer and downstream valves.

The genuine BY1001012885 is designed for optimal airflow with minimal restriction. This allows the compressor to operate at peak efficiency, building air pressure quickly and reliably.

This assembly is more than just a hose. It is an engineered system. It typically routes air from a relatively clean location in the engine bay to the compressor.

Many Shacman intake assemblies incorporate a centrifugal pre-cleaner or cyclone chamber. This uses vortical action to spin out heavier dust and particles before the main filter.

The hose itself is constructed from materials resistant to oil, heat, and abrasion. It must remain flexible and airtight across a wide temperature range without cracking.

Connectors and clamps are designed for a secure, vibration-proof fit. Vibration is a constant in heavy trucks, and loose connections are a common source of air leaks.

Trucks operate on construction sites, mines, and unpaved roads where dust concentration is extreme. The intake assembly must handle this punishment day after day.

The materials in the genuine part are selected for UV resistance and longevity. Cheap rubber hoses can degrade quickly under hood heat and sunlight exposure.

Proper routing, secured with the correct brackets, prevents chafing against other components. The OEM assembly BY1001012885 comes with all necessary hardware for correct installation.

The Compressor Intake Assembly is not a one-size-fits-all component. Its design, hose length, and connection points vary depending on the truck model and compressor location.

Part number BY1001012885 is specified for particular Shacman chassis and compressor configurations. Using the correct assembly ensures it fits within the engine bay layout.

An incorrect hose may be too short, causing tension, or too long, creating loops that can kink and restrict airflow. Kinks are a common cause of poor compressor performance.

The connection to the compressor inlet and the air source must be airtight. The genuine part’s fittings are machined to match the OEM compressor and air filter housing precisely.

The assembly is designed to draw air from a specific, clean point. Relocating the intake or using a non-standard hose can inadvertently pull in hot or contaminated air.

Hot air from near the exhaust manifold is less dense, reducing compressor efficiency. Air laden with oil mist from the crankcase breather can coat internal components.

Sticking with the OEM-specified part BY1001012885 guarantees the engineered airflow path is maintained, preserving the system’s designed performance and reliability.

Regular inspection of the compressor intake assembly is a simple yet crucial part of preventative maintenance. It should be checked during every major service interval.

Visually inspect the entire hose for cracks, dryness, abrasion marks, or soft spots. Check all connections and clamps for tightness and signs of air leakage (dust patterns).

Listen for audible hissing near the compressor inlet when the engine is running, indicating an air leak. Ensure the pre-filter or cyclone bowl (if equipped) is emptied of debris.

If the hose is damaged, stiff, or collapsed, replace the entire assembly. Do not attempt repairs with tape or sealant, as they will not withstand the pressure pulsations.

Replacement is straightforward. Ensure the engine is off and the air system is depressurized. Loosen the clamps at both ends of the old assembly and remove it.

Clean the mating surfaces on the compressor inlet and the air source fitting. Install the new BY1001012885 assembly, ensuring it is not twisted or under tension.

Tighten the clamps securely but do not over-tighten, which can cut into the hose material. Start the engine and monitor the compressor’s air build-up time for improvement.

Slow Air Pressure Build-Up: The primary symptom is the air pressure gauges rising slower than normal. The compressor struggles due to restricted airflow or a leak.

Excessive Compressor Cycling: The compressor cuts in and out more frequently to maintain pressure. This indicates it cannot move enough air per cycle due to an intake problem.

Unusual Compressor Noise: Whistling or suction noises can indicate a leak at a connection. A straining or labored sound may point to a blockage or collapsed hose.

Contaminated Air System: If the pre-filter is missing or broken, excessive dirt can enter, leading to premature wear on the compressor, air dryer, and valve components.

A simple diagnostic test is to temporarily run the compressor with the intake hose disconnected (in a clean environment). If performance improves dramatically, the assembly is restrictive.

Check for a collapsed hose by feeling along its length while the compressor is running. A vacuum can cause weak spots in old hoses to suck closed.

Inspect the air filter element serving the intake source. A clogged main air filter can also starve the compressor, mimicking intake assembly failure.

Universal intake hoses and cheap imitation parts pose significant risks. Their material may not meet the same heat and oil resistance standards, leading to premature hardening and cracking.

They often lack the integrated pre-cleaning features of the OEM assembly. This leaves the compressor more vulnerable to abrasive wear in dusty conditions.

The fit is rarely perfect. Universal hoses may require cutting to length, risking improper interior cleanliness and potentially leaving sharp edges that disrupt airflow.

The genuine BY1001012885 is a complete, ready-to-install kit. It includes all necessary components for a perfect, reliable fit, saving time and eliminating guesswork.

The cost of a new air compressor is many times higher than the price of a genuine intake assembly. Protecting the compressor with the correct part is excellent preventative economics.

Downtime caused by a failed compressor can strand a loaded truck, resulting in missed deadlines and high recovery/repair bills. Prevention is always cheaper.

Using the Shacman part ensures compatibility with the vehicle’s warranty and maintenance records, which is important for fleet management and resale value.

The air brake system is a safety-critical system. Every component that affects its performance, including the compressor intake, must be considered a safety item.

A reliable air supply ensures the air reservoirs fill quickly after engine start and recover promptly after heavy braking. This is essential for maintaining adequate system pressure.

In emergency braking situations, having full system pressure available can make a vital difference. A compromised intake indirectly affects brake response and power.

Regular inspection and replacement of the intake assembly with genuine parts like BY1001012885 is a proactive step in any comprehensive vehicle safety program.

A healthy air system reduces strain on the engine. The compressor is typically driven by the engine via a belt. An efficient compressor requires less engine power to operate.

Clean, dry air extends the life of the entire air system: the air dryer, valves, brake chambers, and fittings. This reduces overall maintenance costs over the truck’s lifetime.

For fleet managers, standardizing on genuine Shacman intake assemblies ensures consistency, simplifies inventory, and guarantees a known level of quality across all vehicles.

The Shacman Compressor Intake Assembly BY1001012885 is a fundamental yet often overlooked component that directly impacts braking system performance and reliability.

Choosing the genuine OEM part is a smart investment in preventative maintenance. It safeguards the costly air compressor and ensures consistent, reliable air pressure for safe braking.

Do not compromise the air supply to your most critical safety system. Specify part number BY1001012885 for all compressor intake service needs to guarantee optimal performance and durability.

Combine this genuine assembly with regular system inspections and proper air filter maintenance. This holistic approach ensures your Shacman truck’s air brake system remains fully functional, safe, and ready for the demands of the road, mile after mile.