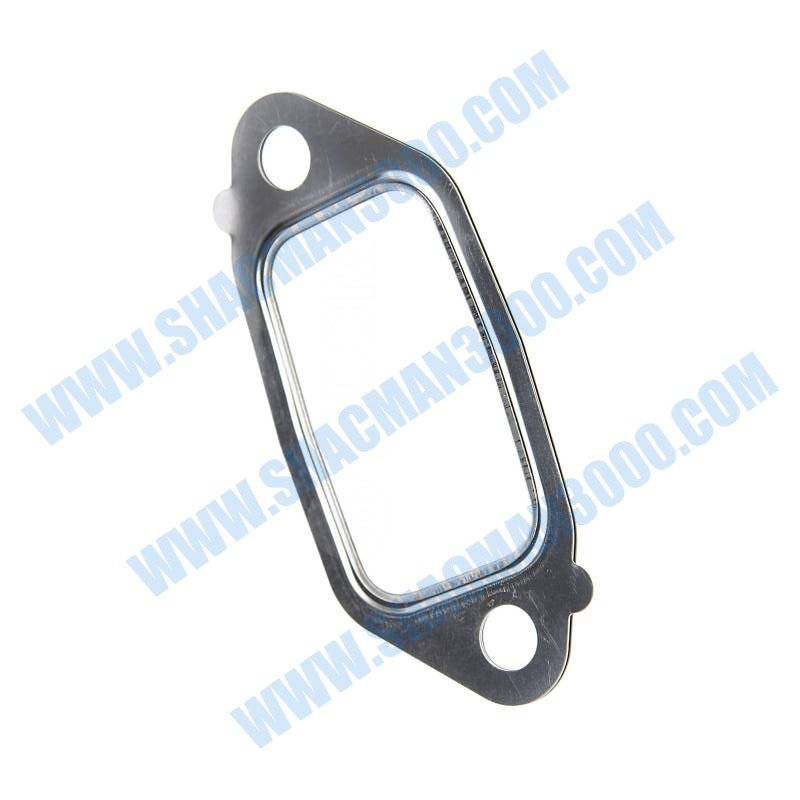

Exhaust Manifold Gasket

Прокладка выпускного коллектора

Junta del Colector de Escape

The Shacman Exhaust Manifold Gasket BY612650110003 is a precision-engineered sealing component critical for maintaining engine efficiency and preventing exhaust leaks. This genuine OEM part, identified by the exact number BY612650110003, creates an airtight seal between the cylinder head and the exhaust manifold, containing high-pressure, high-temperature gases and directing them toward the turbocharger. A failure of this small but vital component can lead to significant power loss, increased fuel consumption, elevated emissions, and the dangerous risk of exhaust gases entering the vehicle cabin. For Shacman trucks subjected to extreme thermal cycling and vibration, using the correct, high-quality manifold gasket is non-negotiable for reliable operation and safety.

Manufactured from advanced multi-layer steel (MLS) or high-performance graphite composites, this gasket is designed to withstand continuous temperatures exceeding 800°C while maintaining seal integrity. Its precise contours and bolt hole patterns ensure a perfect fit for specific Shacman engine models, preventing leaks that compromise engine performance and emissions compliance.

| Parameter | Specification / Value |

|---|---|

| OEM Part Number | BY612650110003 |

| Product Name | Exhaust Manifold Gasket |

| Brand | Shacman |

| Primary Material | Multi-Layer Steel (MLS) or Graphite Composite |

| Continuous Temperature Resistance | Up to 900°C (1652°F) |

| Thickness | Model-Specific (Typically 1.0mm – 2.0mm) |

| Compatible Engine Models | Shacman WP10, WP12, WP13 Series Engines |

| Sealing Function | Cylinder Head to Exhaust Manifold Interface |

| Coating/Finish | Viton Beading, Anti-Stick Coating (MLS) |

| Critical Feature | Accommodates Thermal Expansion & Flexing |

The exhaust manifold gasket is the primary seal between two critical engine components. It must contain extremely hot, pressurized exhaust gases exiting the combustion chambers.

A perfect seal ensures all exhaust energy is directed to the turbocharger turbine. This maximizes boost production and engine efficiency, translating directly to power and fuel economy.

Conversely, a failed gasket allows gases to escape, creating an exhaust leak. This leak reduces turbocharger spool speed, causing noticeable turbo lag and power loss.

Beyond performance, the gasket prevents toxic exhaust fumes, including carbon monoxide, from leaking into the engine bay. This protects both vehicle components and cabin air quality.

Escaping exhaust gases can bypass oxygen sensors. This causes the Engine Control Unit (ECU) to receive incorrect air-fuel ratio data, leading to poor engine management.

The ECU may compensate by adjusting fuel trim, often resulting in increased fuel consumption and higher emissions. This can cause a vehicle to fail emissions tests.

High-velocity hot gases can erode nearby components like wiring harnesses, engine mounts, or plastic lines. This creates secondary, costly damage beyond the initial leak.

Genuine Shacman gasket BY612650110003 utilizes state-of-the-art materials. Multi-Layer Steel (MLS) gaskets are common for this application due to their superior durability.

An MLS gasket consists of multiple thin layers of stainless steel with elastomeric or rubber coatings. This construction allows it to conform to minor surface imperfections.

The layers can slide slightly against each other, accommodating the different thermal expansion rates of the cast iron cylinder head and manifold. This prevents buckling and fatigue.

Graphite composite gaskets are another high-performance option. They offer excellent conformability and natural resistance to extreme heat and chemical corrosion.

The exhaust manifold and cylinder head expand at different rates when heated. A rigid gasket would quickly fail under this constant flexing and shearing motion.

The design of BY612650110003 incorporates strategic embossing, coatings, and material selection to handle this movement. It maintains constant sealing pressure throughout all operating temperatures.

Specialized coatings, such as Viton or fluoroelastomer beads, provide initial soft sealing and resist sticking. This allows for cleaner removal during future service.

This is not a universal gasket. The part number BY612650110003 corresponds to exact port shapes, bolt hole locations, and thickness required for specific Shacman engine families.

Using the correct gasket ensures each exhaust port is perfectly encircled, preventing gas leakage between ports (cross-talk) and to the outside environment.

The thickness of the gasket is precisely calibrated. It can affect the precise alignment of the exhaust manifold to the turbocharger inlet, influencing turbo performance.

Always match the OEM number from the old gasket or the vehicle’s parts catalog. Even small deviations in gasket geometry can lead to immediate leakage or improper sealing.

Gasket thickness affects the “crush” or compression when the manifold bolts are torqued. Correct crush is vital for the gasket to fill microscopic grooves on the metal surfaces.

A gasket that is too thick may not compress enough, leaving a gap. A gasket that is too thin may be over-compressed, losing its resilience and ability to handle thermal cycling.

The genuine Shacman part provides the engineered balance of material and thickness. It ensures optimal sealing from the moment of installation through thousands of heat cycles.

Installation of an exhaust manifold gasket is a precision task. The engine must be completely cool to prevent warping of components and ensure safe handling.

The most critical step is surface preparation. Both the cylinder head mating surface and the exhaust manifold flange must be impeccably clean, flat, and free of old gasket material.

Use a plastic gasket scraper, brass brush, or appropriate chemical cleaner. Avoid using steel scrapers or power tools that can gouge the soft aluminum of the cylinder head.

Carefully inspect both surfaces for warpage, cracks, or deep scratches. A straightedge and feeler gauge can check for flatness. Resurfacing may be necessary if warpage exceeds specifications.

Place the new gasket BY612650110003 over the cylinder head studs, ensuring it sits flat with no wrinkles. Do not use any additional sealant unless specified by Shacman.

Lower the exhaust manifold into place carefully, aligning all bolts. Hand-tighten all nuts or bolts to secure the assembly before final torquing.

Follow the manufacturer’s torque sequence and specification exactly. This is usually a star pattern starting from the center, increasing torque in several stages (e.g., 30%, 70%, 100%).

After the first engine heat cycle (cool down), re-torque the fasteners as specified. This compensates for initial gasket settlement and thermal expansion of components.

Audible Signs: A distinct ticking or tapping sound from the engine bay, synchronous with engine RPM, is the most common symptom. The sound often changes with load and may lessen as the engine warms.

Performance Issues: Noticeable loss of power, especially under acceleration, and increased turbo lag. The engine may feel sluggish and unresponsive due to lost exhaust pressure.

Visual Clues: Black soot deposits around the exhaust manifold/cylinder head joint. You may also see signs of heat discoloration on the manifold or nearby components.

Smell and Smoke: The smell of exhaust fumes near the engine or, more seriously, inside the cabin. In some cases, you might see a small amount of smoke from the engine bay at startup.

Check Engine Light: The ECU may trigger fault codes related to exhaust gas temperature sensor readings, oxygen sensor signals, or turbocharger boost pressure deviations.

Increased Fuel Consumption: The engine computer may enrich the fuel mixture to compensate for perceived lean conditions caused by oxygen sensor inaccuracies from the leak.

Failed Emissions Test: Elevated hydrocarbon (HC) or carbon monoxide (CO) readings during an emissions inspection can directly result from an unmetered exhaust leak.

Generic gaskets often use inferior materials like basic graphite or asbestos blends without protective coatings. These materials can burn out, crumble, or extrude under pressure.

Their dimensional accuracy is frequently poor, with misaligned bolt holes or port shapes. This can lead to improper installation, immediate leaks, or blocked exhaust flow.

Non-genuine MLS gaskets may have fewer layers, thinner steel, or substandard coatings. This reduces their ability to handle thermal cycling, leading to premature failure.

The genuine BY612650110003 is produced under strict quality controls. It is tested for thermal resilience, compression recovery, and gas tightness to meet Shacman’s durability standards.

A failed generic gasket leads to repeat repairs, doubling labor costs and vehicle downtime. For commercial fleets, this downtime directly impacts revenue and scheduling.

Leaking exhaust can cause severe damage to expensive components like oxygen sensors, turbocharger seals, and even the catalytic converter or DPF due to incorrect temperatures.

Investing in the genuine part from the start ensures a reliable, long-lasting repair. It protects the broader engine system and provides peace of mind for operators.

Exhaust manifold gaskets are typically replaced as part of repair, not on a fixed mileage interval. However, they should be inspected during major engine service or if symptoms appear.

Best practice is to replace the gasket anytime the exhaust manifold is removed for any reason. Reusing an old, heat-cycled gasket is a significant risk for future leaks.

During routine maintenance, listen for abnormal exhaust noises and visually inspect the manifold area for soot. Addressing a minor leak early prevents more extensive damage.

Always use a new set of manifold bolts or studs if the old ones are stretched, corroded, or if the manufacturer recommends it. Proper fastener condition is crucial for correct clamping force.

Ensure the exhaust system is properly supported by all hangers. A sagging system can place shear stress on the manifold, distorting the seal and causing the gasket to fail.

Fix engine misfires immediately. Unburned fuel entering the exhaust manifold can cause extreme local heating (afterburning), which can quickly destroy even a high-quality gasket.

Avoid rapid cooldowns, like driving through deep water when the exhaust is extremely hot. Severe thermal shock can cause metal components to warp, breaking the seal.

A properly sealed exhaust system is fundamental for modern emissions control. The gasket ensures all exhaust gases pass through the oxygen sensors and after-treatment devices.

Leaks before the oxygen sensor cause false lean readings, prompting the ECU to enrich the mixture. This increases fuel consumption and emissions of NOx and particulate matter.

By maintaining system integrity, the genuine gasket BY612650110003 helps the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system function correctly.

This compliance is not just about regulations; it’s about environmental responsibility. A well-maintained truck with sealed exhaust systems has a smaller operational footprint.

Every component that improves engine efficiency reduces overall fuel consumption and CO2 emissions. The exhaust manifold gasket, by preventing energy loss, plays its part.

For fleet managers focused on sustainability and total cost of ownership, specifying genuine seals like BY612650110003 is a small but meaningful operational decision.

It supports the goal of running cleaner, more efficient vehicles that meet both economic and environmental targets throughout their service life.

The Shacman Exhaust Manifold Gasket BY612650110003 is a fundamental component for engine performance, efficiency, and safety. Its role is critical, though often underappreciated.

Choosing the genuine OEM part is a direct investment in the operational integrity of your Shacman truck. It guarantees the correct material, dimensions, and durability for the application.

Do not risk engine performance and safety with inferior seals. Always specify part number BY612650110003 for exhaust manifold gasket replacement to ensure a perfect, lasting seal.

Combine this genuine component with meticulous surface preparation, proper torque procedures, and regular system checks. This comprehensive approach ensures maximum uptime, protects your engine investment, and keeps your Shacman truck performing reliably under the most demanding conditions.