Replacing SHACMAN Gearbox Parts is a critical task for maintaining heavy-duty truck performance. This guide covers the 2025 updated procedures.

Follow our illustrated steps for safe and efficient repair of FAST gearboxes commonly used in SHACMAN trucks like X3000 and X5000 series.

Maintaining your SHACMAN truck’s transmission system requires precise knowledge of its parts and service intervals. The durability of SHACMAN Gearbox Parts is legendary, but even the toughest components wear down. Regular maintenance prevents costly roadside breakdowns and extends the transmission’s life significantly. This section details the key components you need to monitor and their recommended replacement schedules based on 2025 industry standards.

Gear oil is the most frequently replaced item. For highway trucks, change oil every 30,000 km. Off-road dump trucks need more frequent changes: every 15,000 km. For extreme conditions like mining, change every 5,000 km. Always use the manufacturer-specified oil grade.

Neglecting oil changes leads to increased friction, overheating, and accelerated wear of internal SHACMAN Gearbox Parts like gears and bearings. Check for metal particles on the drain plug magnet each time.

A successful overhaul relies on having the correct components. Common wearing SHACMAN Gearbox Parts include synchronizer assemblies (e.g., for model 12JS160T), output shaft shims (for X3000 series), clutch release bearings, clutch pressure plates, gear position sensors, and various sealing kits. Keeping these parts in stock minimizes downtime. Sourcing genuine parts is crucial for fit and longevity. The quality of these SHACMAN Gearbox Parts directly impacts shift smoothness and power transmission efficiency.

This hands-on guide walks you through the general process of replacing key SHACMAN Gearbox Parts. Always prioritize safety: use proper jack stands, wear protective gear, and consult the official service manual for your specific model. The process below applies to common FAST transmissions mounted on SHACMAN trucks.

Park the truck on a level surface and engage the parking brake. Place a large drain pan underneath the transmission. Locate and remove the bottom drain plug to empty the old gear oil completely. This is a critical first step before handling any internal SHACMAN Gearbox Parts.

Pro Tip: Inspect the drain plug’s magnetic tip. Excessive metal shavings indicate abnormal internal wear of gears or bearings, signaling a more extensive repair might be needed beyond a simple oil change.

Remove the cabin floor mat to access the gear shift lever base. Carefully detach the shift lever boot or dust cover. Unfasten the shift lever connecting pin or disconnect the shift cable/linkage. This step isolates the transmission from the driver’s controls, allowing for its removal. Always check the condition of the shift lever rubber bushings. Worn bushings cause excessive play and imprecise shifting, so replace them if necessary. Proper maintenance of these external linkages protects the internal SHACMAN Gearbox Parts from misalignment stress.

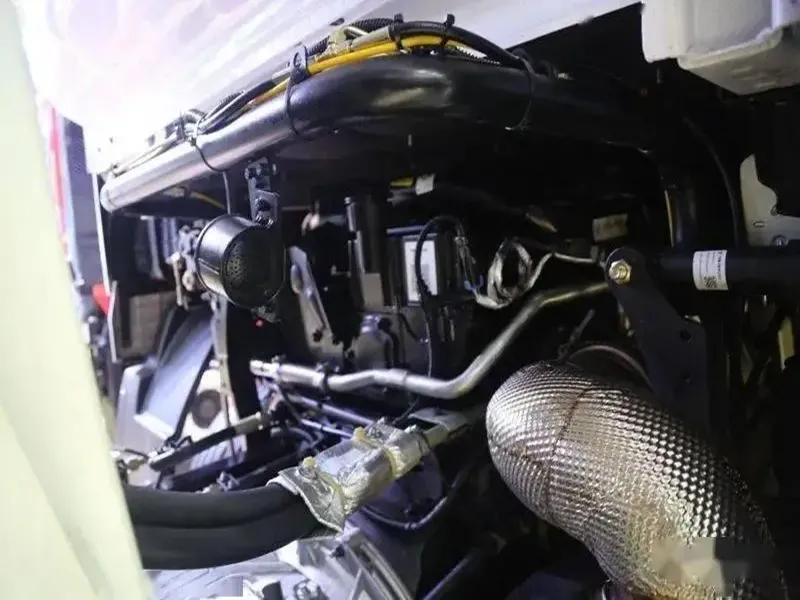

This is the most physically demanding part. Use a dedicated transmission jack or a secure hoist to support the unit’s weight. Remove the propeller shaft bolts, disconnect all air lines (for pneumatic systems), and unplug electrical sensors connected to the SHACMAN Gearbox Parts.

The critical task is loosening the bolts connecting the transmission housing to the engine flywheel housing. Loosen them in a diagonal pattern to avoid warping. Once all bolts are removed, gently slide the transmission straight back, ensuring the input shaft clears the clutch disc. Lower it slowly with the jack.

With the transmission on a clean bench, you can access internal SHACMAN Gearbox Parts. To replace a worn synchronizer, remove the top cover. Locate and detach the shift fork for the specific faulty gear. Carefully extract the old synchronizer assembly. When installing the new one, ensure all sliding keys (dogs) align perfectly with the gear sleeve. The clearance of the synchronizer ring must meet FAST’s original factory specifications for proper operation. Incorrect installation leads to grinding gears and rapid failure. Handling these precision SHACMAN Gearbox Parts requires cleanliness and attention to detail.

The reversal of the removal process demands precision. Hoist the transmission back into position. The most crucial moment is aligning the input shaft splines with the clutch disc splines. Use a clutch alignment tool if needed. Re-bolt the transmission to the flywheel housing, again using a diagonal tightening pattern to the specified torque. Reconnect all lines, sensors, and the propeller shaft. Finally, refill with the correct type and amount of gear oil through the fill port until it reaches the level of the inspection hole. Test shift operation before finalizing the installation of all protective covers and the floor mat. Proper reassembly ensures all new and existing SHACMAN Gearbox Parts work in harmony.

Navigating the world of replacement parts can be challenging. Here is professional guidance to ensure you get the right components and avoid pitfalls during the repair of your truck’s SHACMAN Gearbox Parts.

SHACMAN trucks benefit from good parts commonality across models like X5000, X3000, and F3000. However, assuming compatibility can be costly. Always provide the vehicle’s chassis number (VIN) to your parts supplier. This allows them to cross-reference and provide the exact part number (e.g., 12JS160T-1707140) for the specific SHACMAN Gearbox Parts you need. Using genuine or high-quality aftermarket parts that meet OEM specifications is non-negotiable for reliability.

Be aware that performing a major transmission disassembly yourself, or at a non-authorized repair shop, may void the manufacturer’s warranty on your SHACMAN truck. For complex issues, especially with AMT (Automated Manual Transmission) systems—where problems like failure to engage gear are often linked to sensor modules or clutch actuators—a professional diagnosis with original factory tools is strongly recommended. If your expertise is limited, trusting certified technicians with your SHACMAN Gearbox Parts repair is the safest choice.

For detailed parts catalogs, technical specifications, and to ensure you are getting 100% compatible components for your transmission repair, visit our comprehensive resource center. We provide exploded diagrams and compatibility charts for all major SHACMAN Gearbox Parts.

Learn More