Comprehensive Solutions for SHACMAN Truck Electrical Issues – Keep Your Fleet Running Smoothly

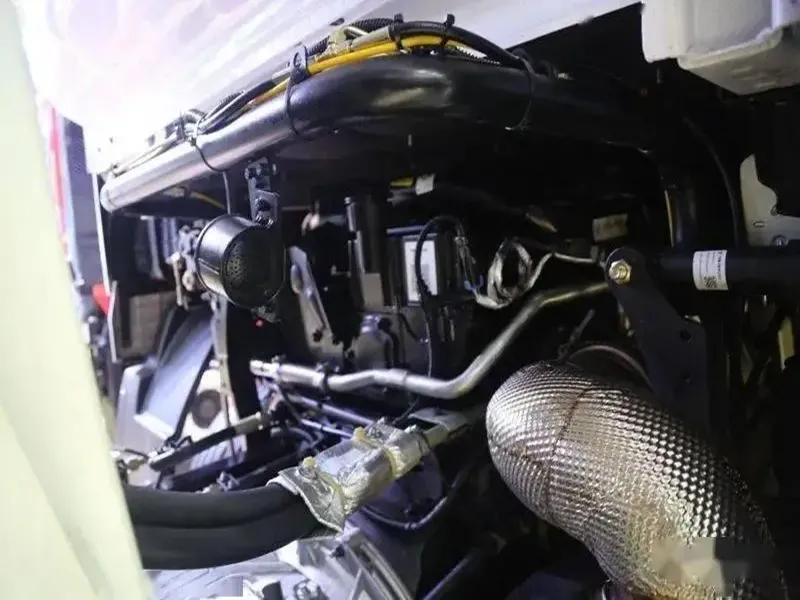

The electrical system is the vital nervous system of any modern heavy-duty truck, and SHACMAN trucks are no exception. Reliable operation depends on high-quality SHACMAN Electrical System Parts. This network, encompassing subgroup 958 for electrical components and 977 for wiring harnesses, manages everything from engine start-up and lighting to advanced monitoring and control functions. When these components fail, it can lead to costly downtime. This guide provides a deep dive into common electrical issues, step-by-step replacement procedures for key parts, and essential maintenance practices to ensure your SHACMAN truck operates at peak performance.

Understanding the intricacies of your truck’s electrical architecture is the first step toward effective troubleshooting and maintenance. Proper handling of SHACMAN Electrical System Parts is crucial for safety and longevity. Let’s explore the most frequent challenges fleet managers and technicians face.

Diagnosing electrical faults begins with recognizing the symptoms. Here are the most prevalent issues associated with SHACMAN Electrical System Parts.

This is often the first sign of trouble. Causes include a weak battery (voltage below 12.6V), a faulty starter motor drawing excessive current, or poor contact in the ignition switch. Corroded battery terminals are also a common culprit affecting the circuit.

Manifesting as complete failure of specific functions like headlights, wipers, or cigarette lighters. This is frequently due to blown fuses, failed relays, or damaged wiring within the harness. Always inspect the corresponding fuse first.

If the battery warning light on the dashboard illuminates while driving, the charging system is likely failing. This can stem from a worn alternator brush, a defective voltage regulator, or a slipping drive belt, preventing the battery from receiving a proper charge.

Modern SHACMAN trucks rely on numerous sensors. Failure of critical sensors (oil pressure, brake pressure, SCR/AdBlue sensors) can trigger dashboard warnings, activate limp mode, or limit engine power. Accurate diagnosis requires reading fault codes from the ECU.

For natural gas models, unique issues may arise. These include stuck high-pressure solenoid valves, abnormal voltage in ignition coils, or spark plug fouling due to carbon buildup. These require specialized knowledge of the dual-fuel system’s electrical controls.

Safety is paramount. Always disconnect the negative battery terminal before working on any electrical component, except when testing the battery itself. Use proper tools and consult the official SHACMAN维修手册 for your specific model.

Location: The main fuse/relay box is typically located under the dashboard on the passenger side. Additional boxes may be found in the engine bay.

Procedure:

A routine but critical task for maintaining reliable SHACMAN Electrical System Parts.

Procedure:

Replacing sensors among your SHACMAN Electrical System Parts often requires precision.

Procedure:

Periodically inspect all visible wiring harnesses (subgroup 977) for chafing, cracks, or burns. Check electrical connection points for corrosion, looseness, or moisture ingress. Keep battery tops clean and dry. A visual inspection can prevent major failures.

While fuses and bulbs are consumables, other parts have expected lifespans. Batteries last 3-5 years, starter brushes wear down, and relay contacts fatigue. Follow SHACMAN’s recommendation: replace critical fasteners like wheel bolts after 10 disassembly cycles to maintain safety.

For complex repairs, always refer to the official SHACMAN Electrical System维修手册. These documents provide circuit diagrams, connector pin-outs, torque specifications, and diagnostic flowcharts specific to your truck’s model and year, ensuring repairs are done correctly.

Understanding the function and maintenance of SHACMAN Electrical System Parts is essential for minimizing downtime and maximizing the reliability of your heavy-duty truck. From simple fuse changes to systematic sensor replacements, a methodical approach ensures safety and effectiveness.

For detailed wiring diagrams, model-specific part numbers, and comprehensive technical support for all SHACMAN Electrical System Parts, we recommend visiting the official resource portal.

Learn More