SHACMAN Chassis Parts

Proper maintenance of SHACMAN Chassis Parts is not just a recommendation; it’s a critical requirement for maximizing the uptime, safety, and profitability of your heavy-duty truck fleet. The chassis forms the backbone of any SHACMAN truck, bearing immense loads and enduring harsh road conditions. Neglecting its core components—the suspension and axles—can lead to premature failure, unsafe driving conditions, and costly unscheduled downtime. This comprehensive 2026 guide delves into the essential maintenance procedures for SHACMAN chassis systems, focusing on the high-performance Hande and genuine SHACMAN components that ensure reliability. By adhering to these scheduled checks and procedures, fleet managers and owners can significantly extend the service life of their vehicles, optimize performance, and protect their investment. Let’s explore the systematic approach to maintaining the structural integrity of your workhorse.

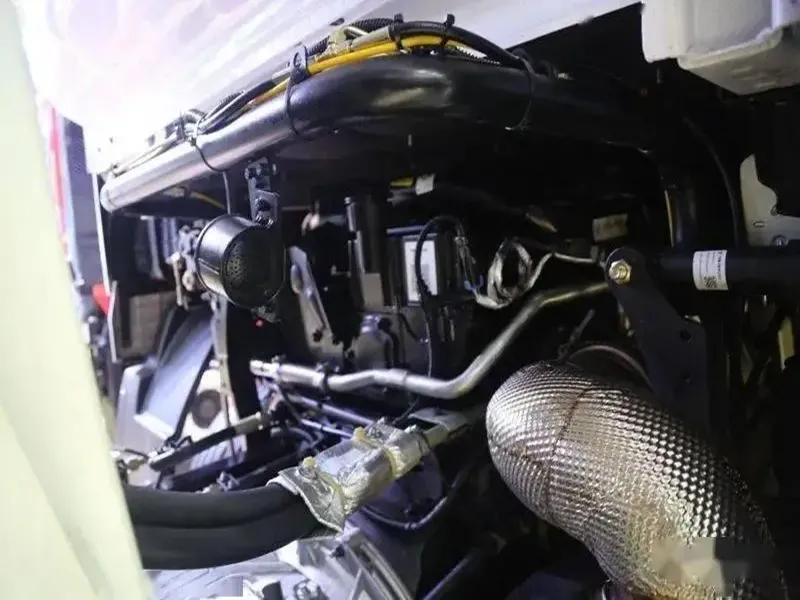

The suspension system is the primary interface between the truck’s frame and the road, absorbing shocks and maintaining stability. For SHACMAN trucks equipped with robust Hande suspension parts, a disciplined maintenance routine is paramount.

All critical fasteners must be checked regularly. This includes U-bolts, center bolts, and all bracket connection bolts. A loose bolt can cause catastrophic misalignment.

For new SHACMAN trucks, a special initial check is vital. Re-torque all suspension fasteners after the first 500 km of operation. Subsequently, follow a strict schedule of re-torquing every 10,000 km.

Always use a calibrated torque wrench and refer to the official SHACMAN service manual for precise torque values. This prevents leaf spring breakage and axle shift.

Leaf springs are the workhorse of traditional SHACMAN chassis parts. Keep them clean from mud, dirt, and road salt to prevent corrosion and friction wear.

During visual inspections, look for signs of a fractured leaf or significant misalignment between spring packs. A broken leaf can drastically change load distribution.

Critical Note: Do not lubricate leaf spring surfaces unless explicitly stated in the vehicle’s manual. Unauthorized lubrication reduces the essential friction damping between leaves.

Modern SHACMAN chassis parts may include air suspension. Inspect air bellows regularly for any cuts, abrasions, cracks, or signs of air leakage. Even a small puncture can cause a system failure.

Verify the vehicle’s ride height matches the manufacturer’s specification. Incorrect height leads to poor drivability, axle hopping, or suspension bottoming out.

Monitor the compressor and dryer for proper operation to ensure clean, dry air supply to the bags.

All suspension pivot points require attention. Regularly apply high-quality, approved grease to shackle pins, balance axle pins, and other lubrication zerks.

Inspect rubber or polyurethane bushings for signs of deterioration: cracking, extrusion, or excessive wear that causes looseness. Worn bushings affect alignment and handling.

Replacing worn SHACMAN chassis parts like bushings promptly restores suspension geometry and ride quality.

The axle is the powerhouse that transfers driving force and supports the vehicle’s weight. SHACMAN axles, often featuring Hande technology, demand meticulous lubrication and adjustment.

Gear Oil Change: Adhere strictly to mileage intervals for changing oil in the main differential and wheel-end reducers. Use only the recommended grade of oil.

Check oil levels at the fill/level plug. The correct level is typically at the bottom edge of the plug hole. Overfilling can cause overheating and seal failure.

For “maintenance-free” SHACMAN chassis parts like certain axles, regular visual inspection of seals is crucial. Look for any oil leaks which indicate seal compromise.

Proper bearing preload is essential for longevity. Listen for unusual humming or grinding noises which indicate bearing wear.

For traditional axles, follow the precise procedure: pre-tighten the bearing nut to a base torque (e.g., 150 Nm), then back it off, and finally re-tighten to a specified angle.

This ensures the correct axial clearance, preventing bearing overheating (if too tight) or hub looseness (if too loose).

Brakes are integral to the axle assembly. For disc brakes (common on Hande front axles), check pad thickness regularly and replace if worn beyond limits.

Ensure brake calipers slide freely on their pins and that dust boots are intact to prevent contamination. For drum brakes, check shoe lining.

Test the function of automatic slack adjusters. They must maintain proper brake chamber stroke. Manually adjust if necessary as a temporary fix.

This small but vital SHACMAN chassis part is often overlooked. The axle breather vent allows internal pressure to equalize with atmospheric pressure.

A clogged vent causes pressure buildup during operation, forcing gear oil past seals and resulting in leaks. Clean the vent during every oil change service.

Ensure the vent is mounted at the highest point on the axle housing for proper function.

Beyond specific tasks, a strategic approach ensures the health of all SHACMAN chassis parts over the vehicle’s lifetime.

Always source replacement SHACMAN chassis parts from authorized dealers or reputable suppliers of OEM-quality components like Hande. Counterfeit parts fail prematurely and can cause collateral damage.

For the most accurate information, download the latest warranty and service manuals from the official SHACMAN download portal. Specifications can change.

The entire chassis is a system. After any significant suspension repair or at regular intervals, perform a full chassis alignment (wheel alignment and axle tracking).

Misaligned axles cause rapid and irregular tire wear, increasing fuel consumption and reducing vehicle stability. This is a key cost-saving measure.

Investing in professional alignment services pays for itself through extended tire life and improved fuel economy.

Record all inspections, torquing sessions, oil changes, and part replacements. A digital log helps predict future maintenance needs and provides a vehicle history.

This data is invaluable for resale and for diagnosing recurring issues with specific SHACMAN chassis parts.

SHACMAN trucks are built for challenging environments, from mining sites to long-haul highways. The chassis components reflect this mission.

High-tensile strength steels are used in axle housings and suspension brackets. Advanced heat treatment processes enhance the durability of gears and shafts.

Partnerships with leading component manufacturers like Hande ensure that SHACMAN chassis parts meet international quality and performance benchmarks.

The design philosophy focuses on serviceability. Common wear items are accessible, and many components are modular for easier replacement.

This engineering reduces the total cost of ownership over the truck’s life, making SHACMAN a prudent choice for fleet operators.

If the truck consistently pulls to one side, it may indicate uneven brake drag, a seized caliper slide pin, or misaligned axles. Inspect related SHACMAN chassis parts immediately. Check tire pressure first, as this is a common cause. If pressure is even, proceed to inspect the braking system and suspension alignment. A professional chassis alignment is often required to correct this issue permanently.

Vibration felt through the steering wheel or cab floor can point to unbalanced wheels, worn drive shaft U-joints, or incorrectly adjusted wheel bearings. The frequency of the vibration often indicates the source: steering wheel shake at highway speeds suggests tire/wheel imbalance, while a rhythmic thump may indicate a separated tire or bent rim. Driveline vibrations are typically felt during acceleration.

Any sign of oil or grease around axle seals, hubcaps, or suspension joints is a direct warning. It often precedes more serious component failure in SHACMAN chassis parts. Gear oil leaks from axle seals can lead to bearing failure due to lubrication loss. Grease leaking from suspension joints indicates damaged seals, allowing contamination to enter and wear the component. Always trace and repair leaks promptly.

Clunking over bumps suggests worn bushings or loose fasteners. Grinding noises may indicate bearing failure. Squeaks often come from dry suspension joints. Metallic clicking during turns can signal worn CV joints on drive axles. A constant howling or whining from the axle often points to worn differential gears or improper bearing preload. Identifying the noise’s location and condition is key to diagnosing failing SHACMAN chassis parts.

Consistent, detail-oriented maintenance of your SHACMAN chassis parts is the most effective strategy to avoid breakdowns, ensure driver safety, and maximize your fleet’s return on investment. This guide provides the framework for a professional maintenance regimen. Remember, using genuine components and following official procedures are non-negotiable for optimal results.

For comprehensive specifications, detailed torque charts, and the latest service bulletins for all SHACMAN chassis parts, we recommend consulting the official resources.

Learn More About SHACMAN Chassis PartsAccess official manuals, parts catalogs, and detailed technical support.