A sudden increase in fuel consumption is a red flag for any SHACMAN truck operator. It often points to failing components that disrupt engine efficiency. Immediate diagnosis and timely SHACMAN Parts Replacement can restore performance and prevent costly downtime.

Common culprits include clogged filters, faulty sensors, and worn fuel system parts. Ignoring these signs leads to higher operating costs and potential engine damage. Proactive maintenance with genuine SHACMAN parts replacement ensures optimal fuel economy.

This guide details the critical components to check. Understanding these can help you make informed decisions about necessary SHACMAN Parts Replacement, saving you money and keeping your fleet running smoothly.

When your SHACMAN truck’s fuel consumption jumps unexpectedly, it’s a system-wide alert. The cause is rarely singular. A methodical check of specific systems and components is essential. Targeted SHACMAN Parts Replacement can effectively resolve the problem.

The engine’s perfect operation relies on precise air-fuel mixture, complete combustion, and free exhaust flow. Any disruption increases fuel use. Let’s explore the systems where component SHACMAN Parts Replacement is most commonly needed.

A restricted air supply forces the engine to work harder, burning more fuel for less power. This makes the intake system a priority for SHACMAN Parts Replacement.

Air Filter: A clogged filter is a primary suspect. It strangles the engine, causing rich, inefficient combustion. Regular inspection and replacement of the air filter are cheap fixes for big savings.

Turbocharger & Intercooler Hoses: Cracks or leaks mean lost boost pressure. The ECU compensates with more fuel. Checking and replacing damaged hoses is a crucial SHACMAN Parts Replacement task.

Air intake components needing attention.

Directly responsible for fuel delivery, issues here cause immediate consumption spikes. SHACMAN Parts Replacement here requires precision.

Fuel Injectors: Worn or dirty injectors leak fuel or spray poorly. This leads to incomplete combustion. Professional testing and replacement of faulty injectors restore spray patterns and efficiency.

Fuel Filter: A blocked filter restricts flow. The engine runs lean initially, but ECU adjustments can later cause over-fueling. Regular SHACMAN Parts Replacement of fuel filters is preventive maintenance.

High-Pressure Fuel Pump: Internal wear reduces pressure, forcing longer injection times. Diagnosis often leads to a necessary pump replacement to ensure correct rail pressure.

Fuel Metering Unit (For Gas Models): Malfunction causes incorrect gas dosing. Accurate replacement of this unit is key for NG truck fuel economy.

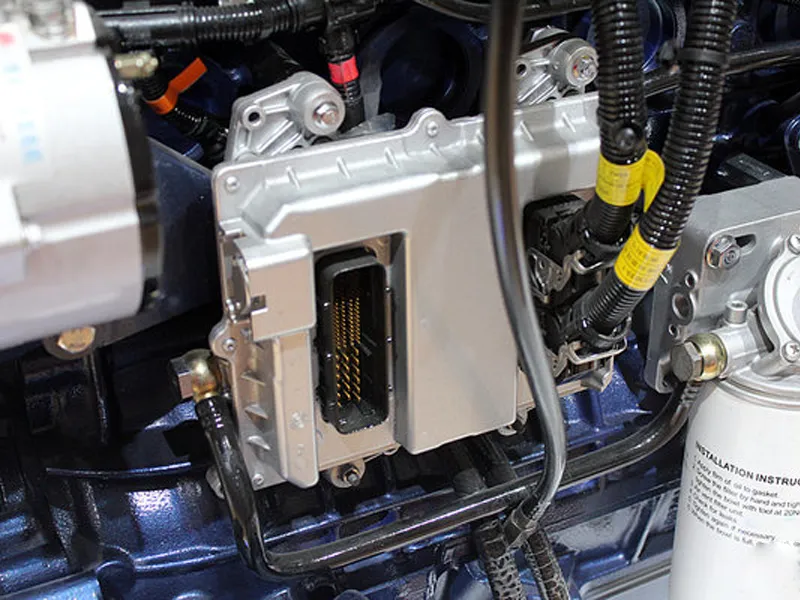

Critical sensors often requiring attention.

Faulty sensors send wrong data to the Engine Control Unit (ECU). The ECU then makes poor decisions, increasing fuel use. Sensor SHACMAN Parts Replacement is common.

Oxygen (O2) / NOx Sensor: A top cause of sudden high fuel consumption. A faulty sensor misreports exhaust oxygen, skewing the air-fuel ratio. Replacing this sensor often solves the issue.

Coolant Temperature Sensor: If it reads “cold” constantly, the ECU enriches the mixture. Replacement of this cheap sensor can yield big fuel savings.

MAP/MAF Sensor: Errors in intake air measurement lead to incorrect fuel calculation. Cleaning or replacement may be needed.

Modern SHACMAN trucks have Diesel Particulate Filters (DPF). A blocked DPF dramatically increases back-pressure.

Diesel Particulate Filter (DPF): Severe clogging forces frequent regenerations, which consume extra fuel. If cleaning fails, a costly DPF replacement might be necessary.

Proper maintenance avoids this. However, when needed, professional SHACMAN Parts Replacement ensures compliance and performance.

Inefficient burning wastes fuel. Certain components directly impact combustion quality.

Spark Plugs (Gas Models): Worn plugs cause misfires and weak ignition. Regular replacement of spark plugs maintains strong combustion.

Engine Carbon Deposits: Excessive carbon alters combustion chamber dynamics. It can cause knocking and inefficient burns. Decarbonization is needed, not always parts replacement.

However, severe cases might require more intensive service. This underscores the value of quality SHACMAN Parts Replacement from the start.

These systems affect rolling resistance. Problems here make the engine labor unnecessarily.

Transmission Fluid: Dirty or low fluid hurts efficiency. The engine revs higher for same speed. Fluid change is maintenance; severe neglect may demand SHACMAN Parts Replacement of transmission components.

Brake Components: Sticking calipers or dragging brakes create constant resistance. This is a mechanical issue often solved by replacing pads, calipers, or sliders.

Clutch (Manual): A slipping clutch wastes engine power. It requires replacement of the clutch assembly to restore power transfer.

Drivetrain parts for maintenance.

Sometimes, simpler issues mimic major faults. Always rule these out first before embarking on extensive SHACMAN Parts Replacement.

Dirty or incorrect oil level increases friction. Use recommended grade and change intervals. This simple step can delay costly component replacements.

Under-inflated tires raise rolling resistance significantly. Check pressure weekly. It’s a zero-cost fix that improves mileage, avoiding unnecessary repairs.

A stuck-open thermostat keeps engine cool. ECU enriches mixture. Replacing a faulty thermostat is a minor but effective repair.

Blindly replacing parts is expensive. Follow a logical diagnostic sequence to pinpoint the exact need for repairs.

This method ensures your repair is accurate and cost-effective. It transforms guesswork into a precise solution.

For critical components, always opt for genuine parts. Counterfeit or low-quality alternatives may seem cheaper but lead to repeated failures.

Genuine SHACMAN Parts Replacement guarantees correct specifications, fit, and durability. They are engineered for your truck’s specific model and engine.

This ensures optimal performance and fuel economy after repair. It protects your investment and maintains resale value.

To explore genuine components and get expert advice on your specific situation, learn more through our dedicated resource portal. This is a valuable step before committing to any major service.

A sudden fuel consumption increase in your SHACMAN truck is a solvable problem. The key is systematic troubleshooting.

Focus on the air intake, fuel system, sensors, and exhaust aftertreatment. Often, one component’s failure triggers the issue. Timely SHACMAN Parts Replacement restores efficiency.

Regular preventive maintenance reduces the frequency of emergency repairs. It keeps fuel costs predictable and your truck reliable.

Remember, proper diagnosis saves money. Don’t replace parts randomly. Use data and expert guidance to make informed decisions. Your fleet’s profitability depends on it.

Addressing fuel consumption proactively with correct SHACMAN Parts Replacement is not an expense; it’s an investment in operational efficiency and long-term asset health. Stay vigilant, maintain regularly, and always choose quality parts for your SHACMAN truck.