A clean and functional EGR (Exhaust Gas Recirculation) valve is vital for your Shacman truck’s performance, fuel efficiency, and emissions compliance. Neglecting this crucial component can lead to power loss, rough idling, and increased pollution.

This comprehensive guide details both cleaning and replacement procedures for the Shacman EGR valve. Whether you’re tackling routine maintenance or addressing a fault, following the correct steps ensures longevity and optimal engine operation.

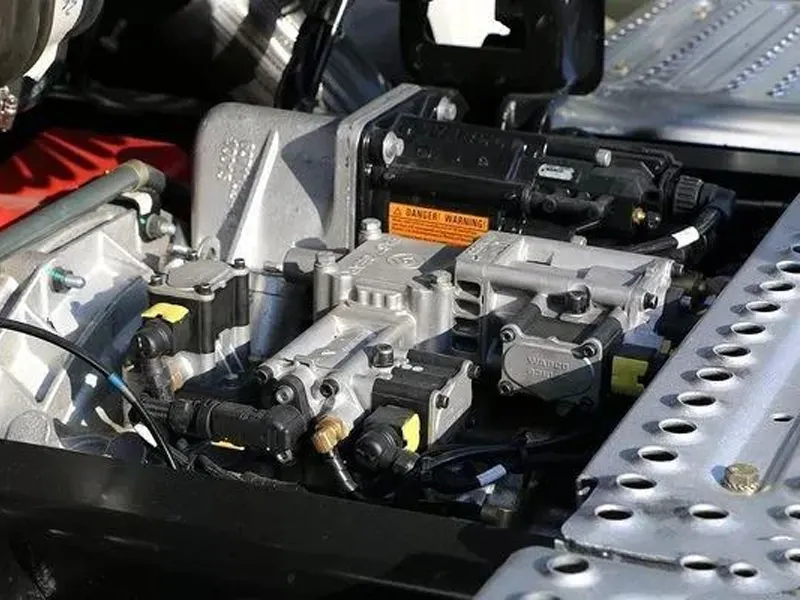

Shacman EGR Valve

The Shacman EGR valve is an emissions control device. It recirculates a portion of the engine’s exhaust gas back into the intake manifold. This process lowers combustion temperatures. Lower temperatures significantly reduce the formation of harmful nitrogen oxides (NOx). This helps the Shacman truck meet stringent environmental regulations.

However, this process comes with a downside. Exhaust gases contain soot and carbon particles. Over time, these particles accumulate inside the EGR valve and its passages. This buildup restricts flow, disrupts the valve’s precise operation, and can cause a range of engine performance issues.

Cleaning is a cost-effective solution for moderate carbon deposits. Follow this detailed procedure to restore your Shacman EGR valve function.

Park the truck on a level surface and engage the parking brake. Allow the engine to cool completely to avoid burns. Disconnect the negative battery cable to prevent electrical shorts. Gather your tools: EGR/carburetor cleaner, safety glasses, gloves, soft brushes, and a set of wrenches.

Locate the EGR valve. It is typically mounted on or near the intake manifold. Carefully disconnect the electrical connector. Remove any attached vacuum or coolant hoses, noting their positions. Unbolt the valve from the manifold. Gently lift it away, being mindful of the old gasket.

Soaking: Spray the valve interior and passages thoroughly with a dedicated EGR cleaner. Let it soak for 10-15 minutes to break down stubborn carbon. For heavy deposits, a longer soak in a safe solvent may be needed.

Scrubbing: Use non-metallic brushes (toothbrush, pipe cleaners) to gently dislodge the softened deposits. Avoid metal tools to prevent scratching the sensitive valve seat and pintle mechanism.

Rinsing and Drying: Blow out all passages and components with compressed air. Ensure all solvent and carbon debris are removed. Let the valve air dry completely. No moisture should remain before reinstallation.

Clean the mounting surface on the intake manifold. Install a new gasket (recommended) or carefully reinstall the old one if perfectly intact. Position the clean Shacman EGR valve. Hand-tighten bolts first, then torque them to the manufacturer’s specification in a crisscross pattern. Reconnect all hoses and the electrical connector. Reconnect the battery.

When cleaning is insufficient, replacing the Shacman EGR valve is necessary. This procedure follows similar initial steps but requires extra care with the new component.

Follow the safety and removal steps from the cleaning guide. Once the faulty valve is off, thoroughly clean the manifold mounting surface. Remove all traces of the old gasket and carbon. A clean, flat surface is essential for the new valve to seal properly.

Always use a brand-new gasket. Position it on the clean manifold surface. Unpack the new Shacman EGR valve. Avoid touching the internal moving parts. Carefully place the valve onto the studs or alignment pins. Hand-start all bolts to prevent cross-threading.

Using a torque wrench, tighten the bolts gradually in a crisscross sequence to the specified torque value. This ensures even pressure and prevents warping. Reconnect all electrical, vacuum, and coolant lines securely.

This step is crucial for modern Shacman trucks. Reconnect the battery. Use a professional-grade diagnostic scan tool to clear any historical EGR-related fault codes from the Engine Control Unit (ECU). Many newer engines require an EGR valve “relearn” or “adaptation” procedure. This allows the ECU to calibrate and recognize the new valve’s position sensor for accurate operation. Consult your truck’s service manual for the specific procedure.

Start the engine. Listen for unusual sounds and visually inspect the installation for any exhaust or coolant leaks. Let the engine reach operating temperature. Take the truck for a test drive under various load conditions. Monitor for smooth acceleration, stable idle, and the absence of warning lights.

The decision depends on the valve’s condition. Cleaning is a preventive maintenance task. It is ideal for routine servicing when performance issues are minor. If the valve is mechanically stuck, the diaphragm is leaking, the electronic actuator has failed, or cleaning does not resolve the problem, replacement is the only reliable solution. A genuine Shacman EGR valve ensures perfect fit, performance, and durability.

Wrench and socket set, screwdrivers, torque wrench, safety glasses, gloves.

EGR or carburetor cleaner, soft-bristle brushes, pipe cleaners, compressed air can.

New Shacman EGR valve, new gasket, diagnostic scan tool with heavy-duty software.

To extend the life of your Shacman EGR valve and the entire engine system, follow these tips. Use high-quality diesel fuel with low sulfur content. Adhere to the recommended engine oil change intervals using the correct specification oil. Ensure the engine’s cooling system is functioning properly, as higher temperatures accelerate carbon formation. Avoid excessive short trips and idling whenever possible.

Regularly inspecting the EGR system during routine service can catch issues early. If you operate in severe conditions (dusty environments, constant stop-and-go traffic), consider more frequent EGR system inspections. A well-maintained EGR system contributes to a cleaner environment and a more profitable trucking operation through better fuel economy and reliability.

Understanding how to properly maintain and service the EGR valve is key to minimizing downtime and repair costs. For detailed specifications, official service manuals, and access to genuine parts, we recommend you learn more through our dedicated platform.