This Shacman Air Brake System Guide provides an in-depth look at the dual-circuit design.

It ensures reliability with auxiliary and emergency systems for heavy-duty trucks.

Learn how compressed air converts to mechanical force for effective braking.

The guide covers components, maintenance, and troubleshooting tips for optimal safety.

Follow this Shacman Air Brake System Guide to enhance vehicle longevity and performance.

Shacman Air Brake System Guide

Welcome to the ultimate Shacman Air Brake System Guide. This resource is essential for truck operators.

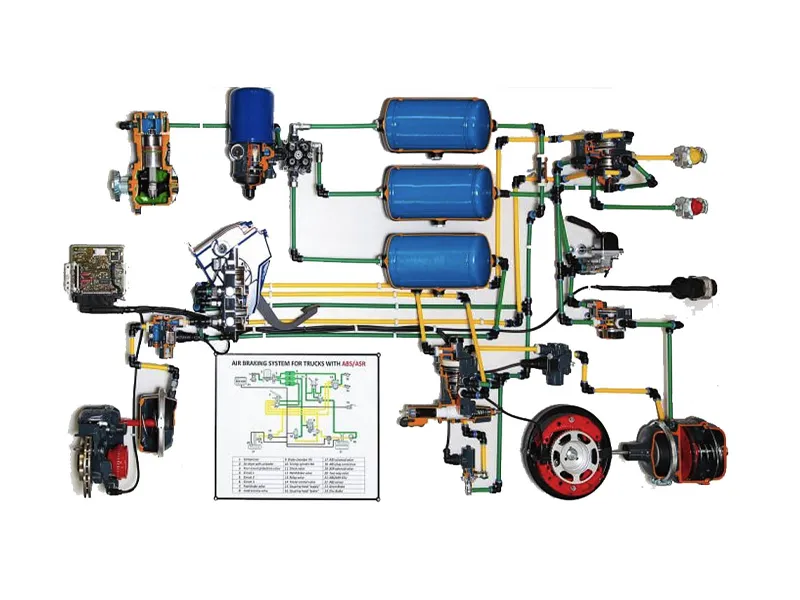

The SHACMAN air brake system uses a dual-circuit design with auxiliary and emergency systems.

It converts compressed air into mechanical force to slow or stop the vehicle efficiently.

This Shacman Air Brake System Guide will help you understand safety and reliability features.

By following this guide, you can ensure optimal performance in various driving conditions.

The system starts with an engine-driven air compressor pumping air into storage tanks.An air dryer removes moisture to prevent damage, ensuring clean compressed air.When the brake pedal is pressed, air flows to brake chambers near the wheels.This air pressure converts to mechanical force, activating slack adjusters and S-Cams.Finally, brake shoes press against drums to generate friction and stop the truck.

The air compressor is engine-driven. It pumps air from the atmosphere into tanks.

This component is vital for maintaining adequate pressure in the braking system.

The air dryer removes moisture and contaminants. It prevents rust and freezing.

Regular service of the dryer is crucial for system longevity.

These tanks store compressed air. SHACMAN uses multiple tanks for different circuits.

They ensure a steady supply of air during braking operations.

The foot valve controls air flow. When pressed, it regulates pressure to brake chambers.

It acts as the primary interface for the driver to apply brakes.

Brake chambers convert air pressure into mechanical force. They push pushrods linked to slack adjusters.

These are located near each wheel for direct action.

Slack adjusters convert linear motion from pushrods into rotational motion of S-Cams.

They ensure proper brake shoe engagement with drums.

These friction components convert kinetic energy into heat. They slow the vehicle down.

Regular inspection for wear is essential in the Shacman Air Brake System Guide.

Relay valves speed up brake application on long vehicles. They allow air from local reservoirs.

This reduces lag time for improved safety.

Spring brakes are used for parking and emergencies. They engage automatically if air pressure is lost.

This fail-safe mechanism is a key feature in the Shacman Air Brake System Guide.

This valve enhances safety. It ensures independent circuit operation in case of failure.

It is a critical component for reliability.

This is the primary dual-circuit air brake system. It is controlled by the pedal.Used for normal driving stops, it ensures smooth deceleration.

It uses engine energy for deceleration. Often includes exhaust brake or hydraulic retarder.Reduces wear on main brakes, especially on long slopes.

Operates via spring brake cylinders on rear axles. Activated manually or automatically.Engages upon main system failure for safety.

An independent system for semi-trailers. Controlled by a separate valve.Enhances control when towing heavy loads.

Daily checks are crucial. Drain air receivers to check for water or oil discharge.

This indicates potential air dryer issues that need immediate attention.

Regular inspections include checking brake pad wear and adjusting shoe gaps.

Inspect all pipelines for air leaks to maintain system integrity.

Service the air dryer every two years or 200,000 kilometers. Replace the desiccant cartridge.

This ensures proper moisture removal and prevents damage.

Follow this Shacman Air Brake System Complete Guide for scheduled maintenance routines.

Brake failure can be caused by low fluid levels, leaks, or worn pads.

Uneven braking force or noise often points to improper adjustment or wear.

A warning light or buzzer indicates pressure drop below critical levels.

For example, if pressure falls below 0.55 MPa, park immediately and inspect.

Refer to the Shacman Air Brake System Complete Guide for step-by-step diagnostic procedures.

Common issues include frozen lines in cold weather or contaminated air.

Regular maintenance from this guide can prevent most problems.

The dual-circuit design offers redundancy. If one circuit fails, the other still works.

This enhances safety for heavy-duty truck operations on rough terrains.

Auxiliary brakes reduce heat buildup, extending the life of main brake components.

Spring brakes provide fail-safe parking and emergency stopping capabilities.

The system is designed for durability, with components resistant to wear and tear.

Using this Shacman Air Brake System Guide, operators can maximize efficiency.

SHACMAN trucks with this air brake system are used in construction and mining.

They are ideal for long-haul transportation where reliable braking is critical.

The system performs well in extreme weather conditions, from heat to cold.

It is also suited for off-road applications, thanks to its robust design.

This Shacman Air Brake System Guide helps in selecting the right model for needs.

Always perform pre-trip inspections. Check air pressure gauges and listen for leaks.

Train drivers on proper braking techniques to minimize wear and tear.

Use the auxiliary brake on descents to save the main braking system.

Keep a log of maintenance activities as recommended in the Shacman Air Brake System Guide.

Store replacement parts like air dryer cartridges for timely servicing.

Explore more detailed insights, technical specifications, and advanced tips.

了解更多Service every two years or 200,000 km. Replace the desiccant cartridge as needed.

It ensures independent circuit operation for safety during partial failures.

Yes, the air dryer prevents freezing. Follow the Shacman Air Brake System Guide for winter tips.

Listen for hissing sounds or use soapy water on connections during inspections.

This Shacman Air Brake System Guide covers all aspects from components to maintenance.

By adhering to the guidelines, you can ensure safe and efficient truck operations.

The dual-circuit design with auxiliary systems makes SHACMAN brakes reliable.

Regular use of this Shacman Air Brake System Guide will prevent costly breakdowns.

Remember, safety first—always prioritize brake system checks and updates.