Mastering the “Complete Guide to SHACMAN WP12 Engine Maintenance” is essential for any fleet manager or owner-operator. This definitive resource provides step-by-step procedures, from daily checks to major overhauls, ensuring your 11.6L workhorse delivers unmatched reliability, fuel efficiency, and a lifespan exceeding 1,000,000 km. Adherence to this **Guide to SHACMAN WP12 Engine** minimizes downtime and maximizes return on investment.

Core Focus: Routine schedules, troubleshooting, and expert tips.

Key Benefit: Prevents costly repairs through proactive care.

For Whom: Technicians, drivers, and heavy equipment owners.

Guide to SHACMAN WP12 Engine

The SHACMAN WP12 engine is a cornerstone of heavy-duty operations. This Complete Guide to SHACMAN WP12 Engine Maintenance is your roadmap to preserving its power and durability. Neglecting proper upkeep leads to a cascade of issues: increased fuel consumption, loss of power, excessive emissions, and catastrophic failure. Systematic maintenance, as outlined in this **Guide to SHACMAN WP12 Engine**, is the most cost-effective strategy for asset management.

It transforms reactive, expensive repairs into predictable, budgeted service tasks. Understanding the interplay between the fuel system, air intake, cooling, and lubrication is what this guide delivers. Every check and procedure in the **Guide to SHACMAN WP12 Engine** is designed to keep your engine within its optimal operating window, ensuring it pulls heavy loads day after day without complaint. The goal is longevity and unwavering performance, and this manual is the key.

Your Complete Guide to SHACMAN WP12 Engine Maintenance starts with daily habits. Before ignition, perform a visual walk-around. Look for fresh puddles or stains indicating oil, coolant, or fuel leaks. Check all hose connections and pipe clamps for tightness. Inspect the air intake system for damage that could allow unfiltered air to enter. Verify fluid levels using the dipstick for engine oil and the translucent reservoir for coolant.

The coolant level should be between the “MIN” and “MAX” marks when the engine is cold. Never open a hot radiator cap. Listen attentively during the cold start for any unusual knocks or rattles. Observe the exhaust smoke color briefly at startup; excessive blue or white smoke warrants investigation. These five minutes can prevent 95% of roadside emergencies.

Adhering to a time or mileage-based schedule is the core principle of this Complete Guide to SHACMAN WP12 Engine Maintenance. The following intervals are general; always defer to your official operator’s manual for specific model variations. The structured plan in this **Guide to SHACMAN WP12 Engine** ensures no critical task is overlooked.

This is the most critical routine service. Drain the engine oil when warm to suspend contaminants. Always replace the oil filter simultaneously. Using an old filter contaminates new oil instantly. For the WP12, use high-quality SAE 15W-40 oil meeting API CI-4 or CK-4 specifications. The oil capacity is approximately 38 liters. Refill slowly and check the dipstick level after a brief run. Inspect the cooling system. Check coolant concentration with a refractometer; a 50/50 mix of glycol and distilled water is ideal. Inspect all belts for cracks, fraying, or glossiness. Adjust tension if necessary. A loose belt squeals; an overtightened belt strains bearings.

Pro Tip: Before removing the old oil filter, clean the housing area. Smear a thin layer of new oil on the filter gasket before installation to ensure a perfect seal. This best practice is highlighted in the **Guide to SHACMAN WP12 Engine**.

Replace both primary and secondary fuel filters. Always prime the fuel system after replacement to prevent airlocks and hard starting. Drain water from the fuel-water separator daily in humid climates. Inspect the air filter element. Use the restriction indicator as your guide; if it shows red, replace immediately. Never run the engine without an air filter. Check the turbocharger for axial and radial play by gently moving the compressor wheel. Minimal movement is normal; excessive play indicates bearing wear.

This is a precision task best performed by trained technicians, as referenced in your materials. Incorrect valve clearance causes poor performance, excessive noise, and can damage valves and pistons. The engine must be at operating temperature before adjustment. The specified clearance for the WP12 is typically 0.30 mm for intake and 0.40 mm for exhaust valves. This adjustment, detailed in the **Guide to SHACMAN WP12 Engine**, ensures optimal combustion and engine breathing.

Beyond scheduled tasks, this Complete Guide to SHACMAN WP12 Engine Maintenance prepares you for diagnosis and corrective action. The **Guide to SHACMAN WP12 Engine** provides the framework for systematic problem-solving.

Excessive Black Smoke: Indicates incomplete combustion. Causes include a clogged air filter, faulty injectors, low turbo boost pressure, or incorrect injection timing. Start by checking the air filter and intake system for leaks.

Low Power Output: Systematically check air supply (filter, turbo, intercooler), fuel supply (filter, pump pressure), and exhaust backpressure. A clogged DPF or muffler can strangle the engine.

Coolant Loss or Oil Contamination: A serious issue. Check the oil cooler first. If internal, suspect a failed cylinder head gasket or a cracked cylinder head/block. Do not operate the engine.

Winter demands special attention. Use winter-grade diesel with a proper cloud point for your region. Consider anti-gel additives. Ensure your block heater is functional for temperatures below -20°C. The battery must be in top condition, as cold cranking amps (CCA) drop. Use the correct coolant mixture to prevent freezing. Allow the glow plug system to complete its cycle before cranking in very cold weather.

Modern WP12 engines have complex aftertreatment. For the Diesel Particulate Filter (DPF), allow active regeneration cycles to complete. Use low-ash engine oil (API CJ-4/CK-4). For the SCR system, never let the DEF (AdBlue) tank run dry. Use only ISO 22241 certified DEF. Keep the DEF injector nozzle clean. The consumption ratio is typically 3-5% of diesel fuel used. This crucial information is part of a comprehensive **Guide to SHACMAN WP12 Engine**.

This Complete Guide to SHACMAN WP12 Engine Maintenance prioritizes safety and correct methodology.

Dispose of all used fluids responsibly. Never dump oil, coolant, or fuel on the ground or into drains. Used filters contain hazardous residues and must be recycled through approved facilities. Proper waste management is part of professional maintenance as advised in the **Guide to SHACMAN WP12 Engine**.

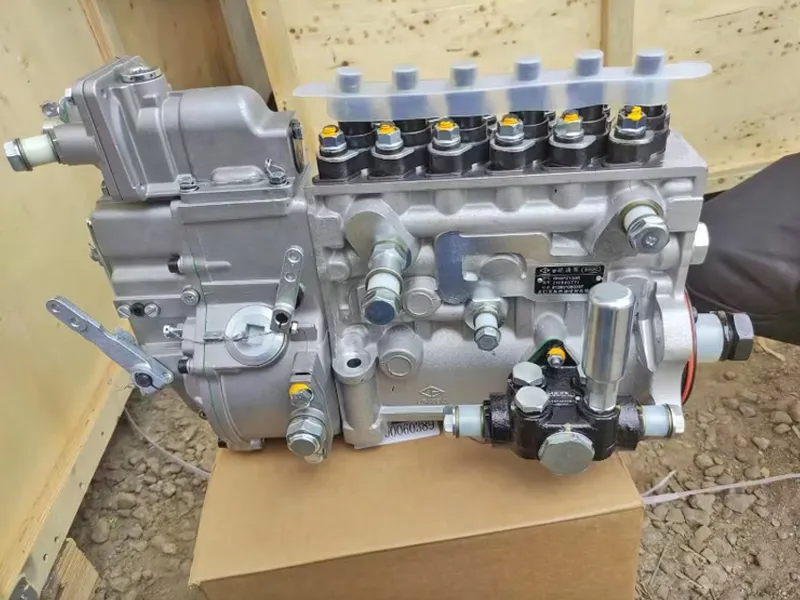

While this Complete Guide to SHACMAN WP12 Engine Maintenance empowers you, know your limits. Seek authorized SHACMAN service for internal engine repairs, complex electronic diagnostics, warranty work, and major component replacement like turbochargers or fuel injection pumps. Their specialized tools and factory training are invaluable for intricate tasks. Learn More about professional support networks and genuine parts sourcing to complement your maintenance regimen.

The true value of this Complete Guide to SHACMAN WP12 Engine Maintenance lies in consistent application. Document every service in a logbook with date, mileage, parts numbers, and observations. This history increases resale value and helps diagnose recurring issues. By treating maintenance not as an expense but as an investment, as outlined in the **Guide to SHACMAN WP12 Engine**, you secure the productivity and profitability of your heavy-duty operation for years to come. Start implementing these procedures today to build a legacy of reliability.