Front Spring Silent Block

Передний Силентблок Рессоры

Silentbloque del Muelle Delantero

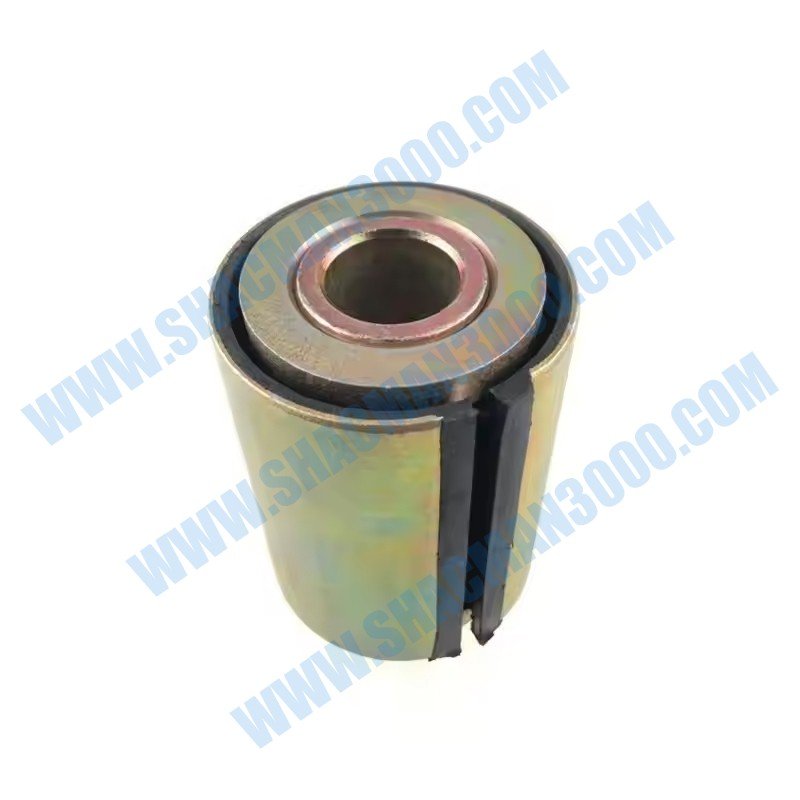

The Shacman Front Spring Silent Block with OEM number 81.43722.0061 represents cutting-edge suspension technology designed to eliminate vibration and noise in heavy-duty truck front suspension systems. This critical component serves as the interface between the front leaf spring and vehicle chassis, providing superior damping characteristics while maintaining precise suspension geometry. Manufactured using advanced rubber compounding and bonding technologies.

Each 81.43722.0061 silent block undergoes comprehensive quality testing to ensure optimal vibration isolation and durability. The specialized rubber compound provides excellent resistance to environmental factors including ozone, UV radiation, and temperature extremes. Professional mechanics trust this genuine Shacman component for reliable suspension performance and extended service life.

The innovative multi-layer design incorporates reinforced steel sleeves and optimized rubber geometry to handle both vertical and lateral forces effectively. This engineering approach significantly reduces road noise transmission to the cabin while maintaining suspension responsiveness. Truck operators appreciate the improved ride comfort and reduced driver fatigue during long hauls.

| Parameter | Details |

|---|---|

| OEM Number | 81.43722.0061 |

| Product Name | Front Spring Silent Block |

| Brand | Shacman |

| Material | Natural Rubber & Steel |

| Outer Diameter | 65mm |

| Inner Diameter | 25mm |

| Height | 45mm |

| Load Capacity | 3,500 kg |

| Temperature Range | -40°C to 80°C |

| Compatible Models | Shacman X3000, F3000, M3000 Series |

| Warranty | 18 Months |

The 81.43722.0061 silent block utilizes premium natural rubber compound specifically formulated for suspension applications. This specialized material provides optimal elasticity and damping characteristics while maintaining structural integrity under heavy loads. The rubber formulation includes anti-aging additives for extended service life.

Reinforced steel sleeves are precisely engineered to provide secure mounting while allowing controlled flexing movement. The bonding process between rubber and metal components undergoes rigorous quality control to ensure permanent adhesion. This material combination withstands constant dynamic stresses without degradation.

Computer-optimized rubber geometry ensures balanced stiffness in all directions, providing consistent suspension behavior. The multi-axis design accommodates both compression and torsion movements simultaneously. Strategic reinforcement patterns prevent premature deformation under extreme conditions.

The integrated dust seals protect internal components from contamination and moisture ingress. Precision manufacturing guarantees exact dimensional accuracy for perfect fitment. Engineering simulations validate performance under various load scenarios and environmental conditions.

The Front Spring Silent Block 81.43722.0061 delivers exceptional vibration isolation, reducing road-induced vibrations by up to 85% compared to worn components. This significant improvement enhances driver comfort and reduces fatigue during long-distance operations. The optimized damping characteristics filter out high-frequency vibrations effectively.

Noise reduction capabilities minimize cabin noise levels, creating a more comfortable working environment for drivers. The consistent performance maintains vehicle quietness across various road surfaces and speed conditions. Professional drivers report noticeably smoother ride quality after installation.

Precise suspension geometry maintenance ensures optimal wheel alignment and tire contact with the road surface. This stability improves vehicle handling characteristics and cornering performance. The controlled flexibility prevents excessive suspension movement during sudden maneuvers.

Extended component life results from the robust construction and advanced material properties. The silent block withstands constant dynamic loading without permanent deformation or performance degradation. Maintenance records show significantly reduced replacement frequency and associated downtime.

The 81.43722.0061 is engineered specifically for Shacman heavy-duty truck models, particularly X3000, F3000, and M3000 series. Comprehensive testing ensures seamless integration with existing front suspension systems. The design matches original equipment specifications precisely for perfect fitment.

Mounting dimensions and interface geometry align perfectly with factory spring hangers and brackets. Installation requires no modifications or additional components. The silent block interfaces correctly with both the leaf spring and chassis mounting points.

This front spring silent block suits various heavy-duty applications including long-haul transport, construction vehicles, and municipal service trucks. The robust design handles diverse road conditions and load scenarios effectively across different operational environments.

From smooth highway operations to challenging off-road conditions, the component maintains consistent performance. The engineering accounts for different suspension configurations and weight distributions. Reliability remains uncompromised in demanding operating conditions.

The 81.43722.0061 features clear installation orientation marks and standardized dimensions. Professional mechanics can complete installation within two hours using standard workshop tools. Comprehensive instructions guide proper pressing techniques and torque specifications.

Alignment indicators assist correct positioning during assembly. The design minimizes installation errors and ensures optimal performance from initial operation. Technical support documentation provides detailed guidance for proper installation procedures and safety precautions.

Routine inspection intervals align with standard vehicle service schedules, typically every 25,000 kilometers. Visual checks for rubber cracking, deformation, and metal corrosion maintain optimal performance. The design allows easy access for inspection during regular maintenance.

Proper installation ensures long-term reliability without requiring additional maintenance. Technicians appreciate the service-friendly design that simplifies inspection and replacement procedures when necessary. Regular maintenance prevents premature failure and ensures consistent performance.

The Shacman Front Spring Silent Block incorporates multiple safety enhancements to prevent sudden failures. The robust construction maintains structural integrity even under extreme overload conditions. Engineering tests validate performance during emergency braking and evasive maneuvers.

Gradual wear characteristics provide visual warning signs before complete failure occurs. The component meets international safety standards for commercial vehicle suspension systems. Regular quality audits ensure consistent safety performance across all production batches.

Professional drivers report increased confidence in vehicle stability and handling predictability. The reliable performance enhances vehicle control during demanding driving conditions. Safety remains the highest priority throughout design and manufacturing processes.

Every 81.43722.0061 unit undergoes rigorous quality control procedures at multiple production stages. Advanced testing equipment validates dimensional accuracy, material hardness, and bonding integrity. Environmental testing simulates extreme temperature and humidity conditions.

The manufacturing process incorporates statistical process control methods to maintain consistent quality. Each production batch must pass strict quality benchmarks before shipment approval. Independent laboratories verify compliance with international automotive standards.

The component meets ISO 9001 quality management system requirements and automotive industry specific standards. Additional certifications include material performance validation and environmental resistance testing. Regular audits ensure continuous improvement in manufacturing processes.

Quality documentation provides complete traceability from raw materials to finished product. This comprehensive approach guarantees consistent product excellence and customer satisfaction throughout the product lifecycle and service intervals.

The 81.43722.0061 delivers exceptional value through extended service life and reduced maintenance requirements. The initial investment provides long-term savings through decreased vehicle downtime and repair expenses. Fleet operators document significant operational cost reductions.

Improved reliability minimizes unexpected failures and associated towing costs. The durable construction eliminates frequent replacement needs, reducing inventory requirements for spare parts. Total cost of ownership analysis demonstrates strong economic advantages over cheaper alternatives.

Enhanced ride comfort contributes to reduced driver fatigue and improved productivity. The superior vibration damping minimizes wear on other suspension components, extending their service life. These factors combine to create substantial operational savings over time.

Reduced maintenance requirements free up resources for other operational needs. The reliability ensures consistent vehicle availability for revenue-generating activities. Business owners appreciate the positive impact on overall fleet profitability and operational efficiency metrics.

Shacman provides comprehensive 18-month warranty coverage for the Front Spring Silent Block 81.43722.0061. This protection includes manufacturing defects and material workmanship, ensuring complete customer satisfaction. The warranty terms reflect the company’s confidence in product quality and durability.

Technical support services offer expert assistance for installation queries and maintenance questions. The support team possesses extensive knowledge of heavy-duty truck suspension systems and requirements. Global distribution networks ensure timely parts availability worldwide.

Customer service representatives provide prompt responses to technical inquiries and operational concerns. The support system maintains detailed service records for continuous product improvement. This commitment to customer care builds long-term relationships and trust with commercial vehicle operators.

The Shacman Front Spring Silent Block 81.43722.0061 represents the pinnacle of suspension component engineering for heavy-duty commercial vehicles. Its superior vibration damping, reliable performance, and safety features make it the preferred choice for professional mechanics, fleet managers, and owner-operators worldwide.

Through continuous innovation and uncompromising quality control, Shacman delivers products that consistently exceed industry expectations. The 81.43722.0061 demonstrates the company’s commitment to excellence and customer satisfaction in every aspect of design and manufacturing.

For commercial vehicle operators seeking enhanced ride comfort, extended suspension durability, and operational reliability, the Shacman Front Spring Silent Block provides a proven solution backed by comprehensive warranty protection and exceptional technical support expertise.