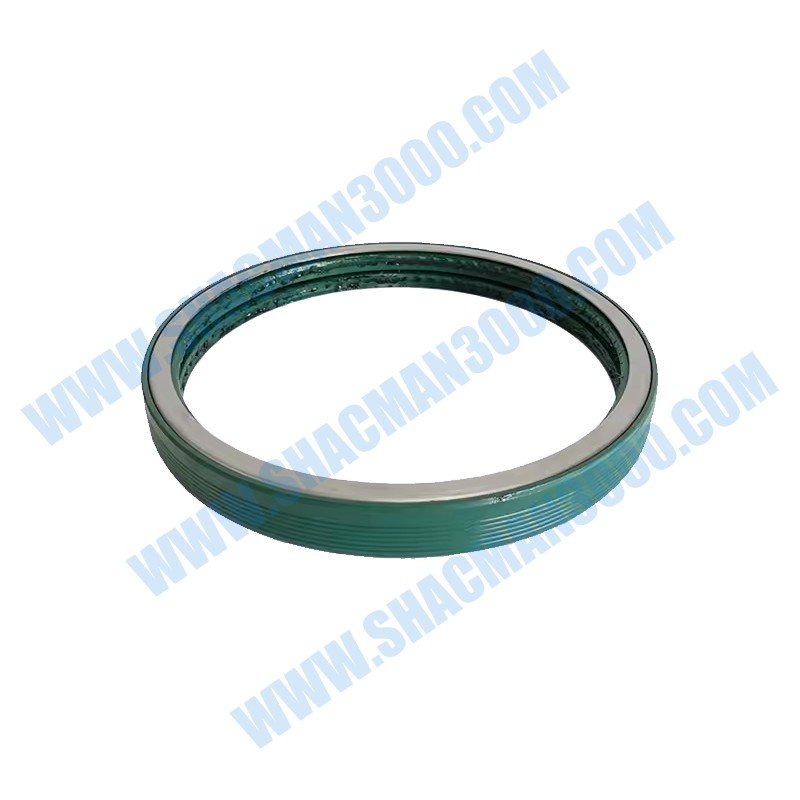

The Shacman Combination Oil Seal, identified by the OEM part number DZ90129340063 and designated for the left side, is a critical sealing component engineered to prevent lubricant leakage and contamination in heavy-duty truck axle systems. This specialized seal is designed for the left wheel hub or axle end of Shacman commercial vehicles, playing a vital role in maintaining the integrity of the differential and wheel bearing assemblies. By effectively retaining high-viscosity gear oil and blocking external contaminants like water, dust, and mud, the DZ90129340063 ensures optimal lubrication, reduces wear, and extends the service life of expensive drivetrain components.

As a genuine Shacman part, this combination seal is manufactured to exacting tolerances using high-quality materials such as nitrile rubber (NBR) for the sealing lip and a sturdy metal outer casing. Its “combination” design typically integrates a primary radial lip seal with an additional dust or exclusion lip, providing dual protection in a single unit. This makes it an essential maintenance item for fleet managers and technicians performing axle overhauls or hub repairs, guaranteeing a perfect fit and reliable performance that matches the original equipment specifications.

| Parameter | Specification |

|---|---|

| OEM Part Number | DZ90129340063 |

| Part Name | Combination Oil Seal (Left) |

| Brand | Shacman |

| Seal Type | Radial Lip Seal with Dust Lip (Double Lip Design) |

| Primary Material | Nitrile Rubber (NBR) Sealing Lip, Steel Outer Case |

| Application Side | Left-Hand Side (Driver’s side in LHD configurations) |

| Compatible Axle/Hub Models | Shacman F2000, F3000 Rear Axle & Front Hub Assemblies |

| Operating Temperature Range | -40°C to +120°C (Continuous) |

| Seal Function | Retain Gear Oil / Grease, Exclude Contaminants |

The Combination Oil Seal DZ90129340063 serves two simultaneous, vital functions. The primary sealing lip is oriented inward, maintaining constant contact with a rotating shaft or housing to keep thick gear oil or bearing grease inside the assembly.

The secondary outward-facing dust lip acts as a barrier against abrasive external particles. This dual-layer defense is crucial for trucks operating in dusty construction sites, muddy roads, or wet conditions, where contamination is a constant threat.

By preventing oil leaks, it ensures the differential and wheel bearings remain properly lubricated. This avoids metal-on-metal contact, overheating, and premature failure, which can lead to costly roadside breakdowns and major component replacements.

The nitrile rubber compound is selected for its excellent resistance to petroleum-based oils, greases, and a wide temperature range. It maintains elasticity and sealing force even after prolonged exposure to heat generated by axle operation.

The metal casing provides structural rigidity for a press-fit installation into the axle housing or hub bore. It prevents the seal from deforming under pressure and ensures it remains securely seated throughout the vehicle’s service life.

As a genuine Shacman part, the DZ90129340063 is manufactured to micrometer-level precision. Its outer diameter (OD) and inner sealing lip diameter (ID) are exact matches for the corresponding axle and shaft dimensions on specified truck models.

This precision eliminates the risk of leaks due to poor fit. Aftermarket seals with slight dimensional variances can lead to “weep” leaks or, conversely, be overly tight, causing excessive heat and wear on the sealing lip.

The seal is designed as a left-side component. It is not interchangeable with the right-side seal due to potential differences in threading or slight design asymmetries in the axle assembly, highlighting the importance of using the correct OEM number.

Proper installation is key to performance. The seal must be driven squarely into its bore using a suitable driver tool to avoid cocking or damaging the metal case. The sealing lip should be lightly lubricated with clean gear oil before shaft insertion.

It is critical to inspect the sealing surface on the companion shaft (axle shaft or spindle) for nicks, rust, or wear grooves. A damaged shaft will quickly destroy a new seal, leading to a recurring leak.

This combination seal is typically found on the wheel end of Shacman’s robust single or tandem rear drive axles. It seals the point where the axle shaft enters the wheel hub, containing the differential oil that lubricates the side gears and bearings.

In some configurations, it may also be used on the differential carrier input shaft (pinion seal) or front steering axle hubs. Its role is consistent: to create a dynamic seal between a stationary housing and a rotating component.

Regular inspection for oil leakage around the axle hubs is a standard part of preventive maintenance. A leaking seal identified by oily residue on the inner wheel or brake components should be replaced promptly with a genuine DZ90129340063.

The most obvious sign is visible oil leakage on the inside of the left rear wheel or a low oil level in the differential housing. Contaminated brake linings from oil spray can also cause reduced braking efficiency.

A howling or whining noise from the axle during operation may indicate bearing wear due to loss of lubrication from a leaking seal. Addressing a seal failure early prevents cascading damage to more expensive internal parts.

The DZ90129340063 seal is formulated to withstand harsh environmental challenges. Its NBR compound resozent degradation from ozone, sunlight, and temperature fluctuations, whether operating in frigid climates or desert heat.

The design effectively handles the constant vibration and minor shaft runout present in heavy truck axles. The sealing lip maintains contact without excessive wear, ensuring a long service interval under dynamic conditions.

By preventing oil loss, it also contributes to environmental protection by reducing soil and water contamination from dripped fluids. This aligns with responsible fleet management and maintenance practices.

Every batch of Shacman oil seals undergoes rigorous quality control. This includes dimensional checks, material hardness testing, and lip spring tension verification to ensure consistent sealing pressure.

Sample seals are tested on simulators that replicate real-world conditions of pressure, temperature, and shaft speed. This validation process guarantees the DZ90129340063 meets the durability standards for heavy-duty commercial use.

The manufacturing process ensures the rubber is bonded permanently to the metal case, preventing any separation that could create a leak path. This bond is crucial for the seal’s integrity over time.

Proactively replacing combination oil seals during scheduled axle servicing is far more economical than dealing with a failure. The cost of the DZ90129340063 seal is minimal compared to the price of new bearings, gears, or a complete axle overhaul.

For fleet managers, using genuine seals reduces the frequency of repairs and associated downtime. A reliable seal helps maintain consistent lubrication, which is the single most important factor for axle longevity.

Keeping accurate maintenance records that include seal replacement helps in predicting future service needs and managing parts inventory efficiently. The OEM number ensures the correct part is always ordered.

Always verify the OEM number DZ90129340063 against your truck’s parts manual or existing old seal. Confirm the application is for the left side of the axle. Using the wrong seal will result in immediate leakage and potential damage.

This seal is designed for specific Shacman axle model generations. While many seals look similar, subtle differences in dimensions or lip design are critical for proper function. Genuine parts guarantee compatibility.

Genuine Shacman seals like DZ90129340063 are engineered as part of a system. They are tested alongside the axle components they protect, ensuring optimal interaction with the specific shaft finish, lubricant, and operating clearances.

Aftermarket seals may use inferior rubber compounds that harden or crack prematurely, or metal cases that are less rigid. This can lead to early failure, repeated repairs, and higher long-term costs despite a lower initial price.

Investing in the genuine part provides peace of mind, supports the vehicle’s warranty (where applicable), and ensures the truck performs reliably, protecting your business’s reputation for on-time deliveries.

The Shacman Combination Oil Seal (Left), OEM number DZ90129340063, is a small but vital component with a massive impact on axle health and truck reliability. Its dual-lipped design offers superior protection against both lubricant loss and contaminant ingress.

Choosing this genuine seal during maintenance is a cost-effective strategy to prevent catastrophic drivetrain failures, reduce environmental impact, and maximize vehicle uptime. It is the specified choice for maintaining the integrity of your Shacman truck’s axle systems.

For precise application confirmation, bulk order inquiries, or technical support, please use the communication channels provided. Ensure your fleet’s longevity with the sealing solution designed by Shacman engineers.