Effective Shacman Electrical System Troubleshooting is crucial for minimizing downtime in heavy-duty trucks. This guide covers systematic approaches, from basic power checks to advanced diagnostics for models like X3000, X5000, and X6000. Mastering these steps ensures reliable performance and avoids costly repairs. Start with simple resets before diving into complex components.

Focus on battery health, fuse integrity, and sensor readings. Use diagnostic tools for error codes. Regular maintenance prevents common issues. This overview highlights key strategies for efficient troubleshooting.

Always refer to official manuals for precise wiring diagrams. Safety first: disconnect power before inspections. Follow our detailed steps to resolve electrical faults quickly.

Shacman Electrical System Troubleshooting requires a methodical process. Begin with visual inspections. Check for loose wires or corrosion. Modern trucks rely on electronic control modules (ECMs). These can malfunction due to software glitches. A system restart often solves 60% of issues. This is vital for X5000 and X6000 series.

Disconnect the battery to drain residual power. Wait at least five minutes. Reconnect and test. If problems persist, proceed to component checks. Always use multimeters for accuracy. Document readings for reference. This approach saves time and money.

Start with the battery. Measure voltage with engine off. For 12V systems, expect 12.6V minimum. For 24V systems, target 24V. Low voltage indicates a weak battery. Clean terminals with a wire brush. Apply anti-corrosion spray. Check the alternator next.

With engine running, voltage should be 26-28V. Readings outside this range suggest regulator failure. Inspect belts for wear. Tighten connections. Fuses and relays are common culprits. Locate fuse boxes in cab and engine bay.

Look for blown fuses with red LEDs. Replace with identical ratings. Test relays by swapping with known good ones. These basic steps form the foundation of Shacman Electrical System Troubleshooting.

After power checks, move to specific symptoms. No-crank issues often stem from starter relays. Test solenoid function. Erratic gauges may signal sensor faults. Use resistance meters on sensors. Oil pressure sensors should read 10-330Ω.

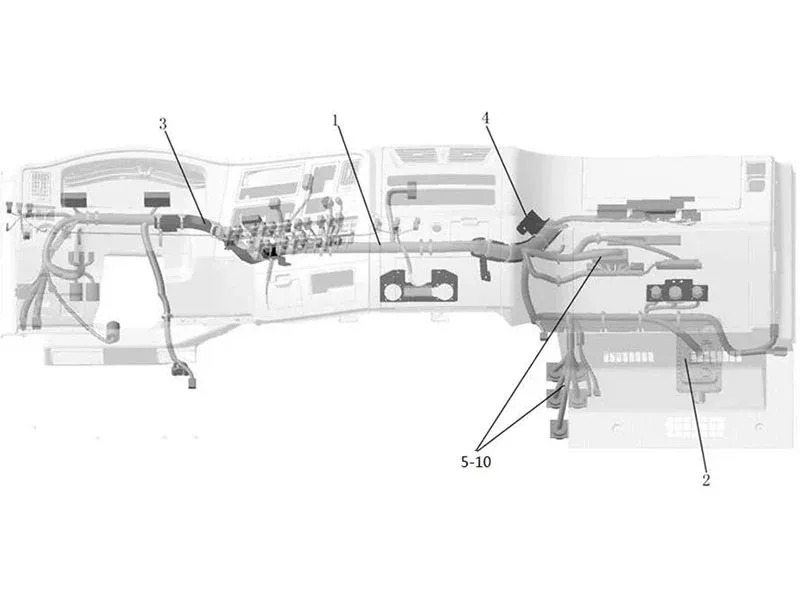

Coolant temperature sensors vary with heat. Compare to standard values. CAN bus failures cause multiple errors. Check wiring harnesses for damage. Secure ground points behind dashboard. This systematic method ensures thorough Shacman Electrical System Troubleshooting.

For complex faults, advanced Shacman Electrical System Troubleshooting is essential. Use diagnostic scanners to read ECU codes. SPN/FMI codes pinpoint issues. For example, Code 43 indicates low gas pressure in CNG models. Interpret codes with manufacturer guides.

Access wiring diagrams from Shacman Service Download Center. Trace circuits for shorts or opens. Test ECM communication with scan tools. Update firmware if available. This reduces intermittent problems. Professional technicians rely on these techniques.

These steps enhance troubleshooting accuracy. Always wear safety gear. Isolate circuits before testing. Record findings for future reference. Advanced Shacman Electrical System Troubleshooting demands patience and expertise.

Focus on electronic control modules. Reset ECMs by disconnecting power. Clear adaptive memory. Recalibrate sensors after repairs. Test drive to verify fixes. Environmental factors like heat affect performance. Park trucks in shaded areas for diagnostics.

Use thermal cameras to spot overheated components. This non-invasive method detects hidden faults. Combine with multimeter readings for comprehensive analysis. Advanced Shacman Electrical System Troubleshooting ensures long-term reliability.

Recognizing symptoms speeds up Shacman Electrical System Troubleshooting. Common issues include black screens, non-responsive gauges, and starting failures. Each symptom has typical causes. Address them step by step.

If the engine doesn’t crank, check battery voltage. Inspect starter relay and ignition switch. Clean battery terminals. Measure voltage drop during cranking. Should not fall below 9V for 12V systems. Replace weak batteries promptly.

Test starter motor directly. Bypass relays with jumper wires. Safety first: ensure transmission is in neutral. Listen for clicking sounds. These indicate relay engagement. No sound suggests faulty wiring. This is core to Shacman Electrical System Troubleshooting.

Erratic instrument clusters often result from fuse failures. Check “Instrument Cluster” fuses. Verify ground connections behind dash. Tighten screws. Use diagnostic tools to test CAN communication. Replace faulty sensors as needed.

Lighting problems involve fuse checks first. Inspect bulbs and connectors. Test switch functionality. For wiper failures, examine relays and motors. Systematic Shacman Electrical System Troubleshooting resolves these efficiently.

Prevention reduces Shacman Electrical System Troubleshooting needs. Regular maintenance is key. Clean battery terminals monthly. Apply dielectric grease to prevent corrosion. Inspect wiring harnesses for chafing.

Secure loose connectors. Check fuse ratings periodically. Keep alternator belts properly tensioned. Monitor charging voltage weekly. Address minor issues before they escalate. This proactive approach saves time and costs.

Following this checklist minimizes electrical faults. Use quality replacement parts. Store trucks in dry environments. Train drivers to report anomalies early. Prevention is integral to effective Shacman Electrical System Troubleshooting.

Invest in protective devices. Surge protectors shield ECUs from voltage spikes. Waterproof covers for exposed connectors. Regular software updates fix bugs. These measures enhance system durability. Less troubleshooting means higher uptime.

Proper tools streamline Shacman Electrical System Troubleshooting. Essential tools include digital multimeters, diagnostic scanners, and wiring diagrams. Multimeters measure voltage, current, and resistance. Use them for continuity tests.

Diagnostic scanners read ECU codes. Choose models compatible with Shacman trucks. Wiring diagrams are available from official sources. Invest in insulated tool sets for safety. Test lights help trace circuits quickly.

A basic kit should have a multimeter with clamp functions. This measures current without breaking circuits. Diagnostic scanner with live data streaming. Allows real-time monitoring of sensor values.

Insulated screwdrivers and pliers. Protective gloves and goggles. Thermal imaging camera for hot spots. These tools empower efficient Shacman Electrical System Troubleshooting. Keep them organized and calibrated.

Software tools include diagnostic apps. Connect via Bluetooth to tablets. Update regularly for new vehicle models. Access online repair databases. These resources complement physical tools.

Advanced tools include oscilloscopes for signal analysis. Useful for CAN bus diagnostics. Battery load testers assess health. Fuel pressure gauges for engine issues. Build a comprehensive toolkit over time.

Training on tool usage is crucial. Attend workshops or online courses. Practice on non-critical systems first. Mastery reduces errors during Shacman Electrical System Troubleshooting.

Real-world examples illustrate Shacman Electrical System Troubleshooting. Case study 1: A 2020 X5000 had intermittent black screens. The solution was a system restart by battery disconnect. This cleared ECM memory fragments.

Case study 2: An X6000 showed erratic gauge readings. Faulty coolant sensor was found. Resistance out of spec. Replacing sensor fixed the issue. These cases highlight systematic approaches.

Always start with simplest fixes. Document symptoms and actions. Use diagnostic data to guide repairs. Share experiences with other technicians. Continuous learning improves Shacman Electrical System Troubleshooting skills.

Case study 3: No-crank problem due to corroded ground. Cleaning and securing ground wire restored function. Emphasize visual inspections. Case study 4: Alternator overcharging damaged battery. Regulator replacement solved it.

These cases show common pitfalls. Avoid assumptions. Test each component methodically. Refer to service bulletins for known issues. Case studies reinforce best practices in Shacman Electrical System Troubleshooting.

Technology evolves Shacman Electrical System Troubleshooting. Future trucks may have AI-driven diagnostics. Predictive maintenance alerts before failures. Wireless updates for ECUs will reduce downtime.

Integrated telematics provide real-time data. Remote troubleshooting via cloud platforms. Enhanced sensors with self-diagnosis capabilities. These innovations will simplify electrical system management.

Technicians must adapt to new tools. Learn software-based diagnostics. Understand network protocols like Ethernet in vehicles. Continuous training ensures competence. The future of Shacman Electrical System Troubleshooting is digital.

Electric and hybrid Shacman models bring new challenges. High-voltage safety procedures. Battery management system diagnostics. Stay updated with manufacturer training. Embrace change for efficient troubleshooting.

Access reliable resources for Shacman Electrical System Troubleshooting. Official service manuals provide detailed schematics. Online forums share practical tips. Manufacturer websites offer software downloads.

Training videos demonstrate procedures. Use genuine parts catalogs for replacements. Subscription services for updated repair information. These resources support accurate troubleshooting.

For a comprehensive guide on advanced techniques, learn more through our dedicated platform. It covers everything from basic checks to complex diagnostics, ensuring you master Shacman electrical systems.

Remember: always prioritize safety. Disconnect power before working on systems. Use personal protective equipment. Follow local regulations. Effective Shacman Electrical System Troubleshooting combines knowledge, tools, and caution.

In summary, Shacman Electrical System Troubleshooting is a critical skill for fleet maintenance. Start with power checks, move to component tests, and use advanced diagnostics when needed. Preventive measures reduce fault frequency.

Keep learning and updating skills. The electrical systems in Shacman trucks are robust but require careful attention. With this guide, you can tackle most issues confidently. Ensure regular practice to stay proficient.

This article has detailed various aspects of Shacman Electrical System Troubleshooting. From initial steps to future trends, we covered essential knowledge. Apply these insights to maintain optimal truck performance. Always refer to official sources for model-specific data.

Thank you for reading. For further details, explore our resources. Mastering Shacman Electrical System Troubleshooting ensures reliability and efficiency in your operations. Stay proactive and systematic in your approach.