Clean Oil is King: The lifeblood of your SHACMAN Turbocharger. Contaminated or low oil is the #1 cause of failure.

Clean Air is Critical: A flawless air intake system prevents abrasive dust from destroying the SHACMAN Turbocharger compressor wheels.

Operate Smartly: Proper warm-up and cool-down routines prevent thermal shock and oil coking in the SHACMAN Turbocharger.

Inspect Regularly: Catching small issues early prevents catastrophic failures and expensive repairs to the SHACMAN Turbocharger.

Following this comprehensive SHACMAN Turbocharger maintenance guide ensures your engine delivers maximum horsepower and torque reliably for hundreds of thousands of kilometers. Proper care of the SHACMAN Turbocharger is essential for optimal truck performance and longevity.

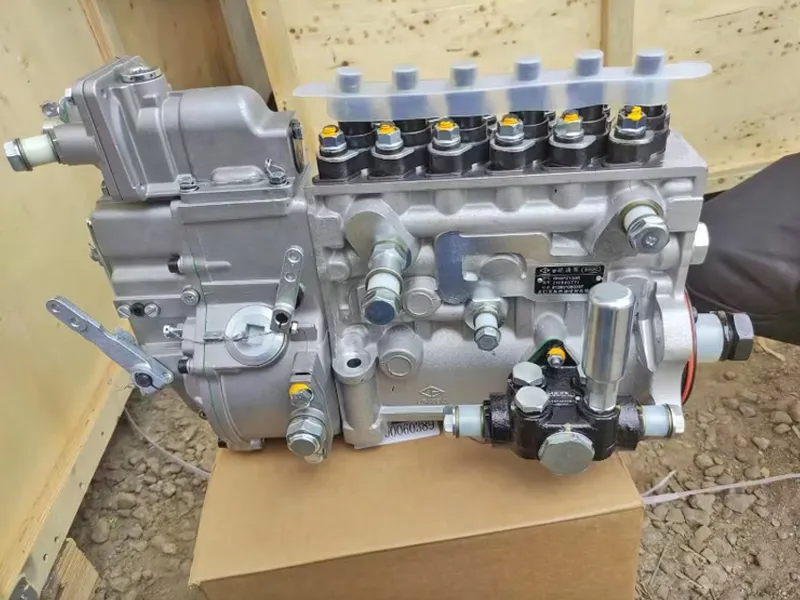

SHACMAN Turbocharger

The SHACMAN Turbocharger shaft spins at speeds exceeding 150,000 RPM, supported by a thin film of oil. Any compromise in oil quality or supply is fatal to the turbocharger’s health.

Adhere strictly to SHACMAN’s intervals for the SHACMAN Turbocharger. For severe duty (dust, short trips, heavy loads), change oil more frequently than standard highway mileage recommends.

Use only recommended API grade oil (e.g., CI-4, CK-4) and genuine or high-quality equivalent filters for your SHACMAN Turbocharger. The oil filter’s bypass valve must function correctly.

After an oil/filter change, crank the engine for 15-20 seconds without starting (disable fuel) to circulate oil and fill the new filter. Never immediately rev the engine to protect the SHACMAN Turbocharger.

A single gram of dust entering the SHACMAN Turbocharger can erode blades and unbalance the assembly, leading to vibration and failure. Protecting the air intake is crucial for SHACMAN Turbocharger longevity.

Check the filter restriction indicator daily. Replace elements as scheduled. In dusty conditions, clean pre-cleaners daily and replace main filters more often to protect your SHACMAN Turbocharger. Never use compressed air to clean a paper filter element, as it can cause micro-tears.

Regularly inspect all clamps, hoses, and pipes from the air filter housing to the turbo compressor inlet and from the outlet to the intercooler and intake manifold. Listen for audible hissing under load, which indicates a boost leak that can strain the SHACMAN Turbocharger.

How you drive significantly impacts turbocharger health. These habits are simple but profoundly effective.

After a cold start, allow the engine to idle for 2-3 minutes. This lets oil pressure stabilize and warm oil circulate to the turbo bearings before they are placed under load.

After high-load operation, idle the engine for 3-5 minutes before shutdown. This allows the turbo shaft speed to drop and heat to dissipate, preventing engine oil from “coking” inside the scorching hot center housing.

Avoid prolonged idling (>30 min) as low oil pressure can lead to seal leakage. Also, avoid sudden high throttle immediately after startup or just before shutdown.

Proactive checks prevent reactive repairs. Use this table as a general guide, but always consult your official SHACMAN manual for model-specific intervals.

| Interval / Check | Action Required | Severe Duty Note |

|---|---|---|

| Daily / Pre-Trip | Check engine oil level. Inspect air filter indicator. Look for leaks. | Mandatory in all conditions. |

| Oil & Filter Change | Replace engine oil and filter with specified grade. | Reduce interval by 30-50% in dusty, stop-start, or heavy-load operations. |

| Air Filter Service | Replace element based on restriction gauge or schedule. | Clean pre-cleaner daily. Inspect weekly. |

| 50,000 km | Complete intake & exhaust system inspection for leaks. Check crankcase breather. | May be required at 25,000 km. |

| 100,000 – 150,000 km | Professional inspection of turbocharger for shaft play, wheel condition, and seal integrity. | Schedule inspection earlier if any symptoms arise. |

Recognizing early warning signs can save you from a complete turbo failure. Here’s a diagnostic guide for common problems.

Symptoms: Truck feels sluggish, lacks pulling power, excessive black smoke.

Likely Causes:

Symptoms: High-pitched whining, grinding, or siren-like sounds from turbo area.

Likely Causes:

Symptoms: Blue smoke (oil burning), Black smoke (unburned fuel).

Likely Causes (Blue Smoke):

Likely Causes (Black Smoke): Often linked to “Loss of Power” causes (insufficient air).

If a turbocharger requires replacement, correct installation is paramount.

Successful SHACMAN turbocharger maintenance hinges on consistency. Make a checklist based on this guide and follow it relentlessly. Investing in proper care is far cheaper than a new turbo and potential engine repairs.

This comprehensive guide provides the foundation for keeping your SHACMAN Turbocharger in peak condition. Remember, the turbo is the heart of your truck’s power and efficiency. By prioritizing clean oil, clean air, and smart operating habits, you ensure maximum reliability and lower total operating costs.

For detailed technical specifications, model-specific service manuals, and access to genuine SHACMAN parts, we recommend you learn more from the official resources.