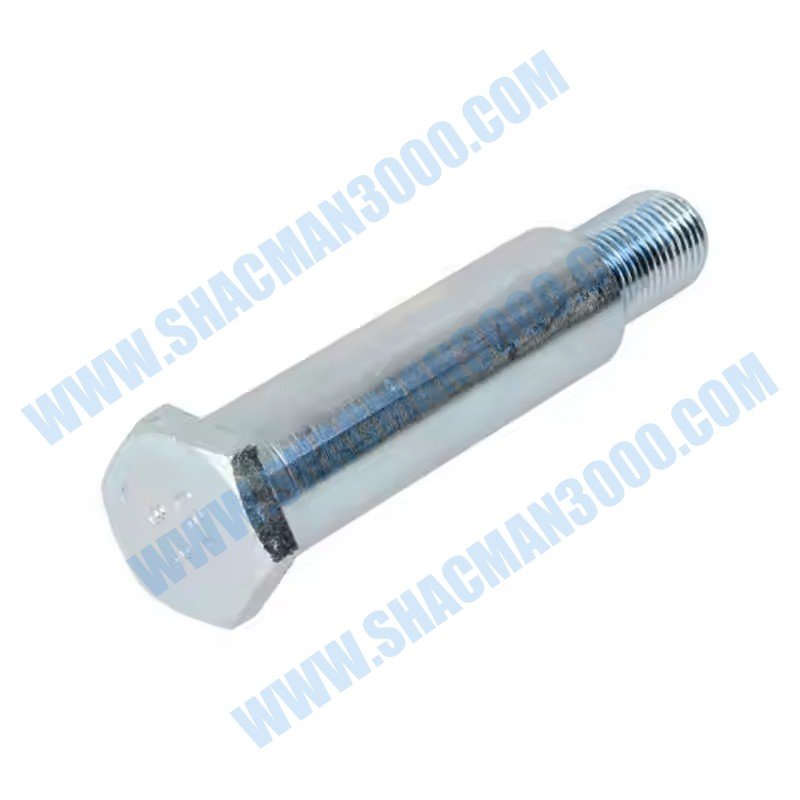

Pin Shaft

Шкворень

Eje Pasador

The genuine Shacman Pin Shaft with OEM number 81910200618 delivers exceptional mechanical connection performance and reliable pivot functionality for heavy-duty truck applications. This critical component ensures precise alignment and smooth rotational movement in various mechanical systems.

Manufactured to exact OEM specifications using premium alloy steel and advanced heat treatment processes, the 81910200618 pin shaft provides superior strength and durability in demanding operating environments. The precision engineering guarantees perfect fitment and extended service life for Shacman suspension and steering systems.

With advanced surface hardening technology and corrosion-resistant coatings, this pin shaft offers unmatched wear resistance and operational reliability. Professional installation with genuine components ensures optimal mechanical performance and prevents premature system failures.

| Parameter | Specification |

|---|---|

| OEM Part Number | 81910200618 |

| Product Name | Pin Shaft |

| Brand | Shacman |

| Material | Alloy Steel 4140 |

| Hardness | HRC 58-62 |

| Diameter | 50mm ±0.01mm |

| Length | 280mm ±0.1mm |

| Surface Treatment | Chrome Plating |

| Compatibility | Shacman Suspension/Steering |

The Shacman Pin Shaft 81910200618 provides exceptional load-bearing capacity and shear strength for demanding mechanical applications. This precision component ensures reliable performance under extreme stress conditions.

Advanced heat treatment processes guarantee optimal material properties and structural integrity. The engineering excellence delivers consistent performance throughout the component’s service life.

Manufactured with chrome-plated surface treatment and precision grinding, this pin shaft offers excellent resistance to abrasion and surface wear. The robust construction handles continuous rotational movements effortlessly.

Premium surface coatings and advanced hardening technologies provide comprehensive protection against mechanical degradation. The durable engineering ensures extended service life with consistent performance delivery.

Each 81910200618 pin shaft undergoes comprehensive quality control procedures throughout the manufacturing process. Exact dimensional precision guarantees seamless integration without modification requirements.

Computer-controlled production systems and automated quality assurance processes ensure uniform product quality and performance consistency. Engineering standards exceed original equipment specifications for reliability.

This genuine Shacman component is specifically engineered for suspension and steering systems in modern heavy-duty trucks. The pin shaft ensures optimal performance across diverse vehicle models and configurations.

Proper installation maintains precise factory specifications for mechanical alignment and operational clearance. Commercial vehicle operators experience enhanced system reliability and improved vehicle control.

The Pin Shaft 81910200618 performs exceptionally well in challenging operating conditions and varied load scenarios. From extreme stress conditions to continuous rotational movements, this component maintains superior performance integrity.

The innovative design accommodates dynamic load changes, frequent directional changes, and continuous heavy-duty use. Various commercial transportation sectors benefit from this premium mechanical solution.

Shacman implements comprehensive quality control measures throughout the complete production cycle. Each pin shaft passes through multiple inspection stages before final approval and packaging.

Advanced testing instrumentation verifies dimensional accuracy, material properties, and hardness characteristics. The manufacturing plant maintains rigorous ISO quality management certification.

Extensive laboratory testing replicates real-world operating conditions to ensure absolute reliability. Load testing and endurance protocols surpass industry standards for safety assurance.

Material testing and surface quality verification confirm performance under extreme mechanical stress conditions. The validation results demonstrate exceptional capability in demanding applications.

Correct installation requires specialized tools and professional expertise for optimal performance results. Certified technicians should adhere to manufacturer-recommended procedures during mechanical system servicing.

Mechanical components must be properly aligned and securely fastened before operational use. Professional installation guarantees reliable performance and prevents potential system malfunctions.

Regular visual inspections during scheduled maintenance help detect potential issues at early stages. Monitor for indications of surface wear, corrosion, or mechanical damage during service intervals.

Pin shaft performance and system integrity should be maintained according to manufacturer guidelines. Component replacement is advised when inspections reveal performance deterioration.

The optimized engineering ensures consistent mechanical performance for improved system reliability and vehicle safety. Properly functioning pin shafts prevent excessive wear in connected components.

The component’s advanced characteristics contribute to stable mechanical operation and precise alignment. This comprehensive protection extends overall system longevity significantly.

Maintaining optimal pin shaft functionality directly influences overall maintenance costs and vehicle uptime. Effective mechanical connections reduce stress on related system components.

The precision engineering minimizes wear in mating components and maintains consistent operational clearance. This contributes to improved vehicle efficiency and reduced operating costs.

Shacman guarantees the quality and performance of every genuine component produced in their advanced facilities. The Pin Shaft includes extensive warranty coverage for complete customer protection.

This commitment demonstrates the manufacturer’s confidence in product durability, reliability, and performance excellence. Customers receive comprehensive support for any verified manufacturing concerns.

Expert technical assistance remains available for installation guidance, troubleshooting, and maintenance recommendations. Shacman’s extensive support network provides professional assistance when needed.

Detailed technical documentation accompanies each product for reference and service guidance. Customers can access additional resources and training materials through authorized service centers worldwide.

Regular inspection during scheduled maintenance helps identify wear patterns before performance degradation occurs. Visual checks should include comprehensive surface condition and dimensional accuracy assessment.

Replacement timing depends on operating conditions, load factors, and specific mileage intervals. Severe service applications may require more frequent inspection and maintenance schedules.

Professional installation by qualified technicians ensures optimal performance, safety compliance, and warranty validation. Certified workshops possess proper equipment for correct mechanical system service procedures.

Proper torque specifications, alignment verification, and clearance checks are essential after replacement. This ensures the complete mechanical system functions as designed by the vehicle manufacturer.

All raw materials undergo rigorous certification processes and quality verification before production begins. Alloy steel components meet or exceed automotive industry standards for mechanical applications.

Surface treatments, heat treatment processes, and protective coatings are extensively tested for durability, performance characteristics, and environmental resistance. Material traceability ensures consistent quality across all production batches.

State-of-the-art manufacturing equipment ensures precision, consistency, and repeatability in production processes. Automated systems maintain tight tolerances and dimensional accuracy throughout manufacturing.

Each production stage includes multiple quality checks, verification procedures, and comprehensive documentation. Final inspection confirms all specifications are met before packaging and customer shipment.

The pin shaft utilizes premium 4140 alloy steel known for its exceptional strength-to-weight ratio and toughness characteristics. This material selection ensures optimal performance in high-stress mechanical applications.

Chromium and molybdenum elements in the alloy composition provide enhanced hardenability and wear resistance properties. The material science behind this component guarantees long-term reliability and durability.

Advanced quenching and tempering processes achieve the optimal hardness range of HRC 58-62 throughout the component. This heat treatment ensures consistent mechanical properties and structural integrity.

Precision temperature control and cooling rates during heat treatment prevent internal stresses and material defects. The resulting microstructure provides excellent fatigue resistance and load-bearing capacity.

Always verify part number 81910200618 before purchase to ensure compatibility with your specific Shacman mechanical system requirements and configurations.

Genuine Shacman parts meet exact engineering specifications and performance requirements for optimal vehicle safety, mechanical reliability, and operational efficiency.

Professional installation by qualified technicians and regular maintenance inspections are essential for achieving optimal performance and ensuring mechanical system integrity throughout service life.