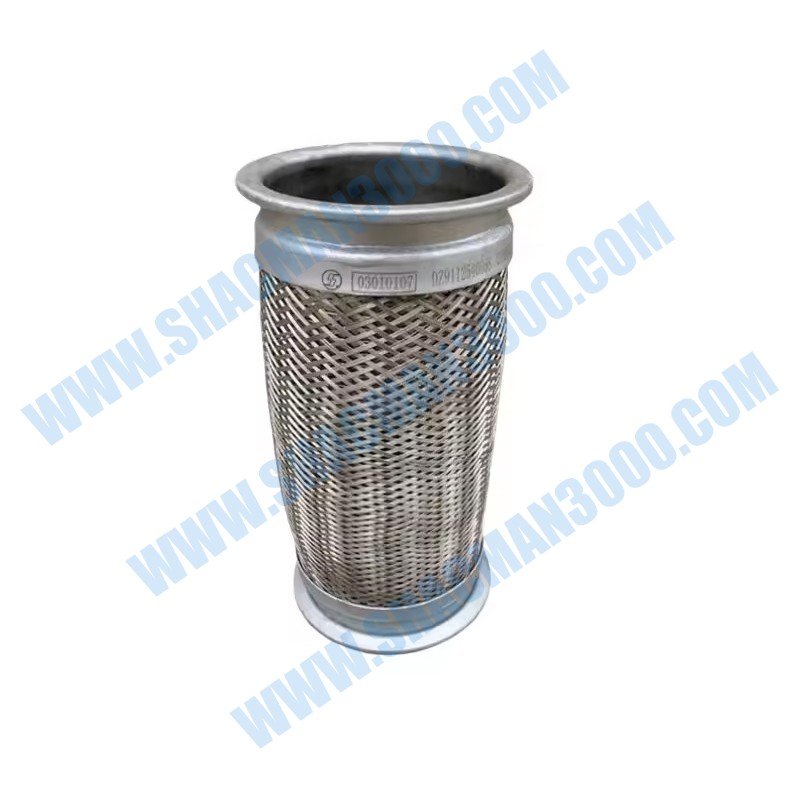

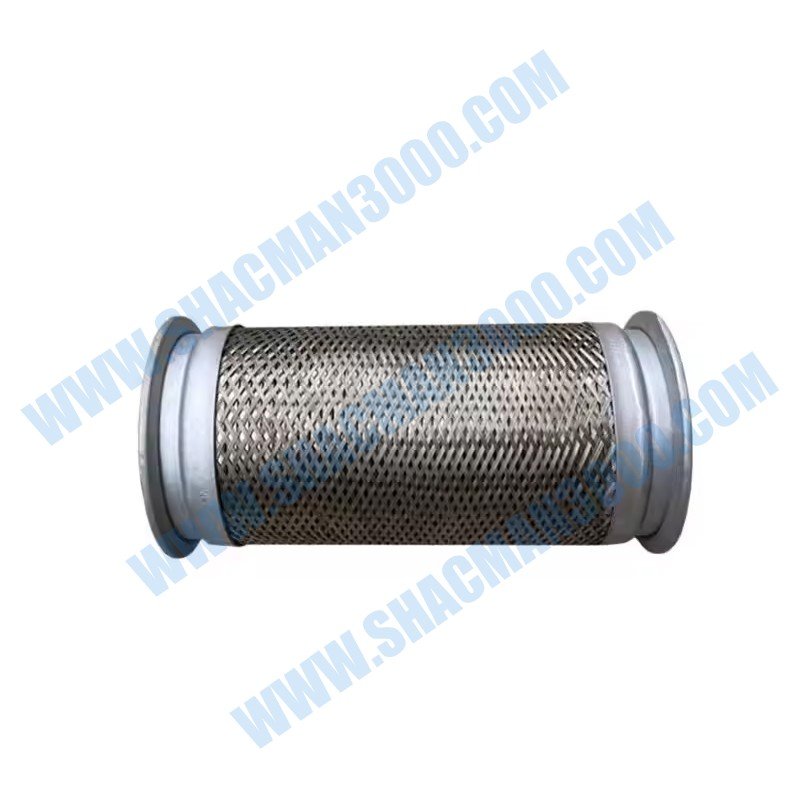

The Shacman Corrugated Hose with OEM number DZ96259530500 is an essential flexible conduit for the Shacman X5000 Truck. Designed for demanding underbody and engine bay applications, this hose provides exceptional durability and vibration resistance. Its unique corrugated structure allows for superior flexibility and movement absorption. The DZ96259530500 hose is engineered to handle the conveyance of air, fluids, or vapors in challenging environments. Using the genuine Shacman part, identified by code DZ96259530500, guarantees a perfect fit and OEM performance standards. Its construction from robust, chemical-resistant polymers ensures long-term reliability. The hose is designed to withstand exposure to road debris, temperature extremes, and constant flexing. This component is critical for the proper function of exhaust, ventilation, or drainage systems. Regular inspection and timely replacement with this genuine part prevent system blockages and leaks.

| Parameter | Details |

|---|---|

| OEM Number | DZ96259530500 |

| Product Name | Corrugated Hose |

| Brand | Shacman |

| Application | Shacman X5000 Truck (Vent/Drain/Exhaust) |

| Material | PP (Polypropylene) or PE (Polyethylene) |

| Inner Diameter (ID) | Vehicle-Specific (e.g., 25mm, 32mm) |

| Length | Precision-Cut to OEM Routing Length |

| Temperature Range | -40°C to +110°C (Material Dependent) |

| Color | Black (Standard) |

| Feature | Crush-Resistant, Flexible, Non-Conductive |

The DZ96259530500 corrugated hose is defined by its distinct ribbed structure. This design provides exceptional lateral flexibility while maintaining excellent axial strength. The corrugations allow the hose to bend smoothly around obstacles without kinking. Simultaneously, they reinforce the wall to resist crushing from external pressure or impact. The inner surface is typically smooth to minimize flow resistance and prevent clogging. The hose is made from thermoplastic polymers like polypropylene, known for toughness. It is inherently resistant to corrosion, unlike metal pipes, and does not conduct electricity. These features make it ideal for complex routing in tight underbody spaces.

Durability is engineered into every fold. The material is UV-stabilized to prevent degradation from sunlight exposure. It remains flexible in sub-zero temperatures, preventing brittle fractures. The hose is also resistant to dilute acids, alkalis, and most automotive fluids. Its one-piece molded construction ensures there are no seams or weak points. The design often includes integrated mounting tabs or flanges for secure attachment. This prevents the hose from flapping or vibrating excessively during operation. These structural attributes contribute to a reliable and maintenance-free service life.

The bellows-like design is key to its functionality. It acts as a flexible joint, absorbing vibrations between connected components. It compensates for minor misalignments during assembly or from chassis flex. The ribs also increase the external surface area, aiding in heat dissipation for certain applications. This design is superior to smooth hoses in applications requiring repeated bending.

Using the genuine DZ96259530500 hose delivers significant practical benefits. It ensures reliable drainage of condensation from air systems and fuel tanks. This prevents water accumulation that can cause corrosion and freeze in winter. In ventilation roles, it safely routes fumes away from sensitive components. Its flexibility simplifies installation and service, reducing labor time. The hose’s durability reduces the frequency of replacements, lowering long-term costs. Fleet managers benefit from fewer roadside failures related to blocked or broken vent lines.

A major operational benefit is system protection. By allowing movement, the hose prevents stress on more expensive, rigid components. It protects against the ingress of dust and debris into critical systems. Its non-conductive nature prevents galvanic corrosion and electrical shorts. The hose also contributes to vehicle safety by ensuring proper venting of fuel vapors. Properly functioning drain hoses prevent electrical malfunctions caused by water intrusion. Overall, this component supports the reliability and safety of multiple auxiliary systems.

The DZ96259530500 is commonly used in several systems on the Shacman X5000. Typical applications include the fuel tank breather/vent line and the air brake system drain lines. It may serve as a transmission or axle breather hose, allowing pressure equalization. It is also used for cab climate control system drains and battery box ventilation. The hose is designed for low-pressure air or liquid drainage, not for high-pressure fluids. Correct identification is crucial, as using it in the wrong system could lead to failure.

Installation is generally straightforward. First, identify the correct routing path, avoiding sharp edges and hot exhaust parts. Cut the hose to the exact required length if it is not pre-sized. Use a sharp blade to ensure a clean, square cut that won’t impede flow. Slide the hose onto the barbed fitting or pipe, ensuring it goes past any bead or ridge. Secure it with a stainless steel clamp, tightening enough to seal but not deform the hose. Ensure the hose has a slight downward slope along its run to facilitate drainage. Never stretch the hose taut; allow some slack for vehicle movement and thermal contraction.

Identify the hose by tracing it from its source. Fuel tank vent hoses run from the tank top to a downward-pointing outlet. Air system drains are usually found on air reservoirs and dryers. Breather hoses are on differentials and transmissions, often terminating high in the frame. Consult the vehicle’s service manual for definitive routing diagrams and hose assignments.

Routine maintenance of corrugated hoses is simple but important. Visually inspect them during regular undercarriage checks, perhaps every 25,000 km. Look for signs of physical damage: cuts, cracks, or crushing from impact. Check for abrasion where the hose may rub against the chassis or other parts. Ensure the hose is not sagging or holding water, which indicates a blockage. Verify that all mounting points are secure and the hose isn’t dangling. Inspect the ends for brittleness or cracking, which is common first. Keeping the hose clear of mud and debris buildup will prolong its life.

Troubleshooting issues with the DZ96259530500 hose is usually straightforward. A blocked vent hose can cause a fuel tank to collapse or not fill properly. A damaged drain hose can lead to water inside the air brake system, causing valve freeze-ups. A crushed or kinked hose will simply stop functioning, causing the system to fail. If a hose is brittle and cracked, it needs immediate replacement as it can suck in debris. When replacing, always check the connecting fittings for damage or corrosion. A persistent issue may indicate a problem with the system itself, not just the hose.

Selecting the genuine Shacman Corrugated Hose DZ96259530500 ensures quality and compatibility. It is manufactured to the precise material grade and dimensional tolerances required. This guarantees the correct flexibility, temperature rating, and chemical resistance for the application. Shacman genuine parts are developed and tested as part of the complete vehicle system. They are validated to endure the specific environmental and mechanical stresses of the X5000. The company provides traceability and support for all its genuine components. The global parts supply chain ensures availability for operators worldwide.

Beyond the part itself, choosing genuine supports overall system integrity. Non-genuine hoses may use inferior plastics that become brittle quickly. Their corrugation pitch or wall thickness might be incorrect, affecting performance. They may not have the required UV stabilizers, leading to premature failure. Genuine parts are engineered to work harmoniously with the clamps and fittings used by Shacman. For a component that protects critical systems from contamination and failure, OEM specification is the safest path. It is an investment in predictable performance and reduced total cost of ownership.

Yes, you can cut it to the required length, but ensure you make a clean, square cut. Avoid cutting it too short, as it needs to fit securely on the barbed fitting without tension.

No. The DZ96259530500 is designed for low-pressure air, vapor, or drainage applications. Engine coolant requires specialized rubber hoses rated for high temperature and pressure.

Use compressed air to blow through the hose from the disconnected end. For stubborn blockages, a flexible cleaning rod may be used carefully to avoid damaging the inner wall.

Absolutely not. Exhaust gas temperatures far exceed the thermal rating of this plastic hose. It would melt and cause a dangerous failure. Use only exhaust-specific components for exhaust repairs.

This is normal. The old hose may have plasticized and softened over time due to heat and fluid exposure. The new, genuine hose has the correct stiffness for optimal performance and longevity.

Ensure the reliable operation of your Shacman X5000’s auxiliary systems with the durable, flexible, and genuine DZ96259530500 Corrugated Hose. A simple component for critical protection.