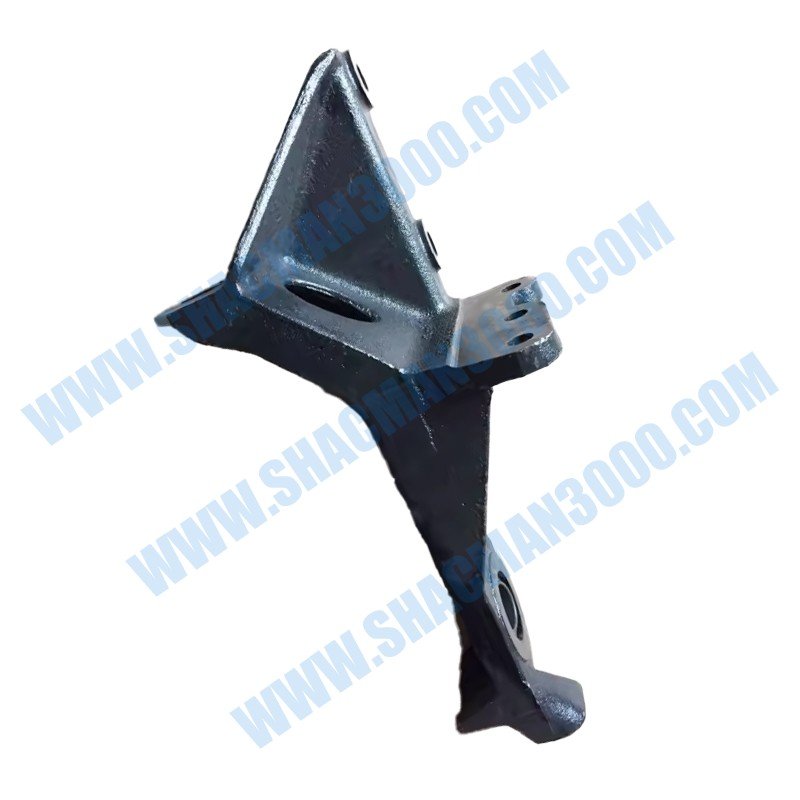

The L Shaped Bracket-120°, identified by the precise OEM number DZ95259189100, is a vital structural mounting component engineered for the Shacman X5000 Truck. This genuine Shacman part is designed with a specific 120-degree angle to provide optimal support and load distribution in complex chassis and cab assemblies. The DZ95259189100 bracket is manufactured from high-strength steel, ensuring it can withstand significant stress, vibration, and torsional forces encountered during heavy-duty operations. Its primary function is to create a secure, angled connection point for various subsystems, including exhaust mounts, wiring harness clamps, or auxiliary equipment brackets. Utilizing the original Shacman bracket DZ95259189100 guarantees perfect geometric alignment, preventing misalignment and premature wear of connected components.

| Parameter | Specification |

|---|---|

| OEM Part Number | DZ95259189100 |

| Product Name | L Shaped Bracket-120° |

| Brand | Shacman |

| Compatible Vehicle | Shacman X5000 Truck |

| Material | Press-Formed Carbon Steel Sheet |

| Angle | 120 Degrees (Internal) |

| Thickness | 4.0 mm |

| Surface Treatment | Zinc Electroplating or Powder Coating |

| Dimensions (L x W per leg) | Variable based on application |

| Hole Quantity & Diameter | Pre-drilled as per OEM blueprint (e.g., 2x Ø10.5mm) |

| Weight | Approximately 0.8 – 1.5 kg |

| Primary Function | Angled Structural Support & Mounting |

The 120-degree angle of bracket DZ95259189100 is a critical design feature. This specific angle is calculated to provide optimal force distribution. It efficiently transfers loads between two connected surfaces that are not perpendicular. The bracket is formed using high-tonnage press brakes for consistency. This ensures every unit has an identical angle and bend radius.

The steel used has excellent formability and strength characteristics. After forming, the bracket undergoes stress-relieving to prevent metal fatigue. Hole placement is determined by CAD software for perfect alignment. This precision eliminates installation struggles and potential bolt shear stress. The design represents a perfect blend of geometric theory and practical application.

This bracket is deployed in several key locations on the X5000. A common use is mounting the exhaust system intermediate support. The 120° angle allows the exhaust pipe to be secured away from the frame. It also provides a stable mount for the rear section of the cab suspension. The bracket can offset mounting points for hydraulic valve blocks.

Another application is within the engine bay for ancillary component support. It might hold the power steering reservoir or an air dryer mounting. Its design is ideal for locations where space is constrained and a right angle won’t fit. The part number DZ95259189100 corresponds to a specific location in the assembly manual. Using the correct bracket ensures all connected systems operate without interference.

The L-Shaped Bracket-120° is designed for both static and dynamic loads. Its geometry resists bending moments more effectively than a 90-degree bracket in certain orientations. Finite Element Analysis (FEA) is used during design to simulate stress points. Reinforcement beads may be pressed into the steel at high-stress areas. This increases rigidity without adding significant weight or material cost.

A seemingly simple bracket plays a direct role in overall vehicle safety. By securely mounting heavy components, it prevents them from becoming dislodged. A failed exhaust bracket, for instance, could lead to a dangerous dragging pipe. The DZ95259189100 ensures critical systems remain anchored during harsh impacts or vibration.

It also maintains proper alignment of moving parts, reducing wear. This prevents unexpected failures that could lead to loss of vehicle control. The zinc plating fights corrosion, which can weaken the metal over years. A strong, corrosion-free bracket is a reliable one, contributing to long-term operational safety for the truck and driver.

Installing the L Shaped Bracket DZ95259189100 requires attention to detail. First, identify the correct mounting location using the vehicle’s service diagrams. Clean the mating surfaces on both the chassis and the component to be mounted. Offer the bracket up to the pre-existing holes; it should fit without force.

Use the specified grade of bolt (usually 8.8 or 10.9). Always employ washers to distribute the clamping force. Tighten bolts in a diagonal sequence to the exact torque value provided by Shacman. Over-torquing can strip threads or warp the bracket, creating a stress riser. Under-torquing can lead to loosening from vibration. A torque wrench is essential for this task.

Regular inspection is key for long service life. During routine maintenance, visually check the bracket for signs of cracking. Pay close attention to the interior corner of the 120-degree bend. Look for any white rust (zinc oxidation) or red rust, especially around bolt holes.

Check that all bolts remain securely fastened. If rust is found, wire-brush the area and apply a zinc-rich touch-up paint. For powder-coated versions, repair chips promptly to prevent under-film corrosion. If the bracket shows significant deformation or heavy rust pitting, replace it. Do not weld repair a cracked OEM bracket; replace it with part DZ95259189100.

The carbon steel provides the core strength required for structural applications. Zinc electroplating offers cathodic protection, sacrificing itself to protect the base steel. Powder coating provides a thick, durable barrier against moisture and chemicals. Some versions may use a combination for maximum longevity. This multi-layer defense is crucial for trucks operating in wet or winter road salt conditions.

The OEM number DZ95259189100 is your guarantee of exact specification compliance. Genuine Shacman brackets are made from steel with a known and tested yield strength. Their forming process is controlled to maintain material integrity at the bend. Aftermarket parts may use inferior, thinner steel or have an inaccurate angle.

A slight angle deviation of even 5 degrees can induce unexpected stress. This can lead to bracket failure or stress on the component it supports. Genuine parts also ensure the hole pattern aligns perfectly, avoiding elongated holes. Investing in the authentic DZ95259189100 bracket protects the value and reliability of your X5000 investment.

The Shacman X5000 is subjected to mining, construction, and long-haul freight. These environments generate constant vibration, shock loads, and exposure to elements. The DZ95259189100 bracket is designed with a fatigue life exceeding the vehicle’s service life. Its material and design resist the cyclic loading that causes metal fatigue cracks.

The protective coating system ensures longevity even when exposed to mud, gravel, and de-icing agents. This durability translates directly into reduced maintenance frequency and cost. For fleet managers, this means higher vehicle availability and predictability in maintenance scheduling. It’s a component built for the real world of heavy trucking.

Every production batch of brackets undergoes rigorous quality checks. Steel coils are certified for chemical composition and mechanical properties. The press brake tooling is regularly calibrated to maintain the precise 120-degree angle. Dimensional inspection uses jigs and gauges to verify leg lengths and hole positions.

Coating thickness is measured with electromagnetic or ultrasonic gauges. Sample brackets are subjected to salt spray testing to validate corrosion resistance standards. This stringent process ensures every DZ95259189100 bracket leaving the factory is identical and reliable. Shacman’s commitment to this level of quality is what defines an OEM part.

The Shacman X5000 uses multiple L-shaped brackets with different angles and sizes. Using part number DZ95259189100 ensures you get the exact 120-degree variant required. Referencing the truck’s VIN and official parts catalog is the best practice. This avoids installation errors that could compromise vehicle assembly integrity and safety.

Q1: Why is the angle specifically 120 degrees and not 90?

A1: The 120° angle is designed for specific spatial constraints and load vector requirements on the X5000 chassis, providing optimal force resolution in its installed orientation.

Q2: Can this bracket be modified (e.g., re-drilled) if needed?

A2: No. Modifying an OEM bracket by drilling or cutting compromises its structural integrity and void any warranty. Always use the correct part for the application.

Q3: Is the bracket supplied with mounting hardware?

A3: Typically, genuine Shacman parts are supplied separately from fasteners. Confirm with your parts supplier if bolts and washers are included with part DZ95259189100.

Q4: What is the expected service life of this bracket?

A4: With proper installation and in the absence of impact damage, the bracket should last the lifetime of the vehicle. Inspect it during major service intervals (e.g., every 150,000 km).

Q5: How do I identify a worn-out bracket that needs replacement?

A5: Visible cracks, severe corrosion (especially where metal is thinning), elongated bolt holes, or permanent deformation (bending) are clear indicators for immediate replacement.

Q6: Is this part interchangeable with brackets from other Shacman models?

A6: No. Part DZ95259189100 is designed specifically for the X5000. Brackets for other models have different part numbers due to variations in angle, thickness, or hole pattern.

The L Shaped Bracket-120°, OEM number DZ95259189100, is a precision-engineered foundation for reliable component mounting on the Shacman X5000. Its specific geometry, robust construction, and protective finishing make it an indispensable part of the truck’s structural ecosystem. Choosing the genuine Shacman part ensures perfect fitment, optimal load handling, and long-term durability.

Do not compromise on the integrity of your vehicle’s support structures. For guaranteed performance and safety, always specify the authentic DZ95259189100 bracket for your maintenance and repair needs. It is a small component that plays a large role in the dependable operation of your heavy-duty truck.

Shacman – Engineered with Precision, Built for Endurance