Condenser

Конденсатор

Condensador

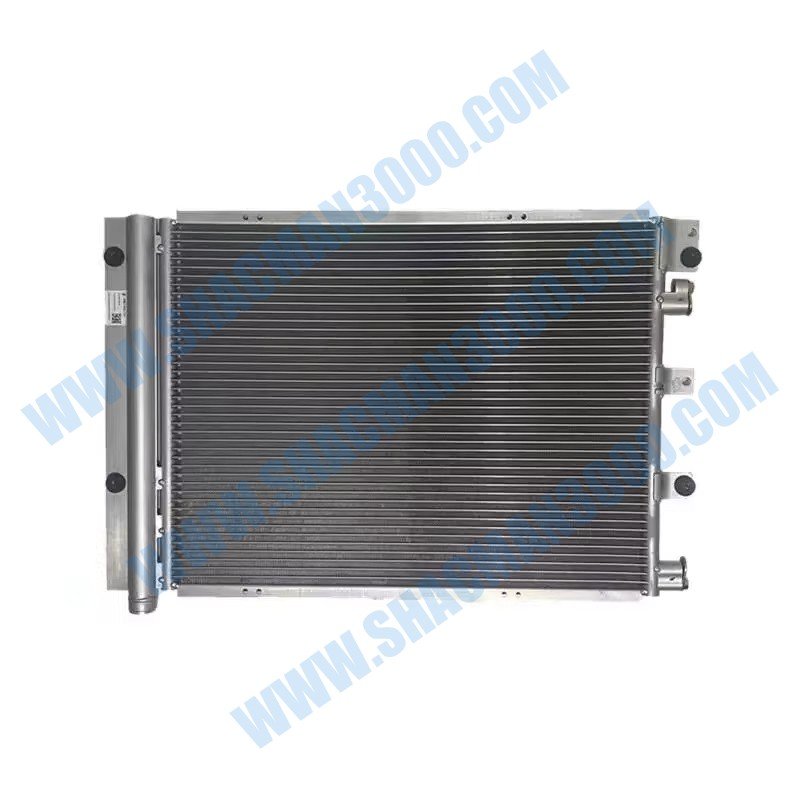

The Shacman Condenser with OEM number DZ14251845057 is a critical heat exchange component in the truck’s air conditioning and cooling systems. This precision-engineered part is responsible for dissipating heat from the refrigerant, ensuring efficient cooling performance for cabin comfort and engine auxiliary systems. Designed for heavy-duty applications, it features a robust aluminum core with serpentine fins and high-pressure tubing to maximize thermal transfer while withstanding vibration, pressure fluctuations, and environmental exposure. The condenser DZ14251845057 is built to deliver reliable operation under extreme temperatures and demanding road conditions.

Its compact yet efficient design ensures optimal airflow and heat dissipation, contributing to lower system pressure and improved fuel efficiency. The unit undergoes rigorous testing for leaks, durability, and corrosion resistance, guaranteeing long service life and minimal maintenance. As a genuine Shacman part, it guarantees perfect fitment and compatibility with specific truck models, restoring factory-level performance and ensuring driver comfort and system reliability across various operational scenarios.

| Parameter | Specification |

|---|---|

| OEM Number | DZ14251845057 |

| Product Name | Condenser |

| Brand | Shacman |

| Compatible Models | Shacman F3000, X3000, M3000 Series |

| Core Material | Aluminum Alloy (Tubes & Fins) |

| Dimensions (LxHxW) | Approx. 750mm x 450mm x 25mm |

| Fin Design | Serpentine, Louvered for Enhanced Heat Transfer |

| Tube Diameter | Multiple Parallel Tubes, 8mm nominal |

| Pressure Rating | Withstands up to 35 bar (507 psi) Operating Pressure |

| Refrigerant Type | Compatible with R134a and R1234yf |

| Connection Type | O-Ring Flare Fittings (Standard) |

| Weight | Approximately 6.8 kg |

| Warranty Period | 24 Months |

The Condenser DZ14251845057 utilizes a multi-flow parallel tube and fin architecture. This design maximizes the surface area for heat exchange between the hot refrigerant and the ambient air. The louvered fins create turbulence in the airflow, breaking the boundary layer and enhancing thermal conductivity significantly.

Optimized tube pathways ensure even refrigerant distribution, preventing localized hot spots and pressure drops. This results in consistent condensing performance, even when the vehicle is idling or operating in high-temperature environments. The efficient design helps the air conditioning system achieve lower discharge pressures.

Constructed from high-grade aluminum alloys, the condenser offers an excellent balance of lightweight properties and structural strength. The materials are chosen for their superior corrosion resistance against moisture, road salt, and chemical exposure. This prevents premature failure and maintains thermal efficiency over time.

The core is mechanically expanded and brazed using nitrogen-charged furnace brazing techniques. This creates leak-proof, strong joints between tubes and fins that can withstand the constant vibration and thermal cycling inherent in truck operations. The end tanks are reinforced to handle high-pressure surges.

Internal baffles and optimized port design within the condenser manage refrigerant flow for phase change from gas to liquid. This precise engineering minimizes pressure loss across the unit, reducing the workload on the compressor. Lower system pressure translates directly into energy savings and extended component life.

The condenser is designed to work harmoniously with the vehicle’s radiator fan and grille airflow. Its profile and mounting ensure it does not obstruct cooling air for the engine radiator, maintaining overall thermal management system balance. This integrated approach is key for vehicle reliability.

The Shacman Condenser DZ14251845057 is engineered for seamless integration into specific Shacman truck models. It is a direct fit for the F3000 series, a workhorse in construction and long-haul transport. These trucks require a robust cooling system to maintain cabin comfort for drivers during extended shifts.

It is also compatible with the X3000 series, which emphasizes driver comfort and operational efficiency. The condenser ensures the air conditioning system performs reliably in various climates. For the M3000 series medium-duty trucks, this component supports HVAC systems in urban delivery and service applications.

This condenser is designed to connect directly to the factory refrigerant lines, receiver-drier, and compressor. The mounting brackets and bolt holes align precisely with the vehicle’s front-end structure. This plug-and-play compatibility eliminates modification needs and ensures system integrity.

Fleet managers should reference the OEM number DZ14251845057 when ordering to guarantee correct fitment. Using this genuine part restores the vehicle’s original cooling capacity and efficiency. It is essential for maintaining warranty coverage and optimal performance in all supported models.

Every Condenser DZ14251845057 is produced under stringent quality control standards. The manufacturing process begins with selecting certified aluminum alloys that meet specific thermal and mechanical properties. These materials are cleaned and treated to ensure optimal brazing and coating adhesion.

Core assembly is performed in a controlled environment to prevent contamination. The brazing process uses advanced furnaces with precise temperature profiles, creating uniform, high-strength bonds throughout the core. This eliminates weak points that could lead to leaks under pressure or vibration.

Each unit undergoes a 100% leak test using helium or nitrogen mass spectrometry. This test detects even microscopic leaks that could compromise system performance over time. Pressure cycling tests simulate years of operation to validate fatigue resistance.

Thermal performance is verified on sample batches using calorimeter test benches. These tests measure heat rejection capacity under simulated operating conditions. Dimensional inspections ensure all connectors and mounting points meet exact OEM specifications for a perfect fit.

Final quality audit includes visual inspection for fin damage, coating uniformity, and proper labeling. Only condensers passing all tests are approved for packaging and shipment. This rigorous process ensures the DZ14251845057 delivers consistent, reliable cooling performance.

Installation should be performed by a qualified technician. Begin by recovering the refrigerant from the system according to environmental regulations. Carefully remove the old condenser, noting the routing of lines and electrical connections for fans or sensors.

Position the new DZ14251845057 condenser, aligning it with the mounting points. Secure it with the specified bolts and brackets, ensuring no stress is placed on the tubing. Reconnect all refrigerant lines using new O-rings lubricated with compatible oil. Reconnect any electrical connectors.

After installation, the system must be evacuated to a deep vacuum to remove moisture and air. Then, charge it with the correct type and amount of refrigerant and oil. Finally, perform a comprehensive system performance test to verify cooling capacity and check for leaks.

Regular maintenance is crucial for longevity. Inspect the condenser fins periodically for debris, such as leaves, insects, or dirt, which can block airflow. Gently clean the fins using a soft brush or low-pressure water spray, taking care not to bend them.

Check for signs of physical damage from road stones or corrosion, especially in winter road salt conditions. Ensure the mounting remains tight and the connections are free from oil residue, which may indicate a leak. Address any issues promptly to prevent system failure.

During seasonal service, have a professional check system pressure and performance. This proactive approach helps identify potential problems before they lead to costly repairs or downtime. Proper care ensures the condenser operates at peak efficiency.

The DZ14251845057 condenser delivers superior cooling efficiency, which translates directly into enhanced driver comfort. A reliable air conditioning system reduces fatigue and improves concentration during long journeys. This contributes to overall safety and productivity for commercial operators.

Its efficient heat transfer design reduces the workload on the compressor. This lowers energy consumption from the engine, contributing to marginal fuel savings over time. Reduced system strain also extends the lifespan of other AC components like the compressor and evaporator.

Durability and corrosion resistance mean fewer replacements and lower lifetime ownership costs. The robust construction withstands harsh environments, from desert heat to coastal humidity. This reliability minimizes unexpected breakdowns and associated repair expenses.

Genuine OEM fit ensures optimal system performance and preserves vehicle warranties. It eliminates compatibility issues that can arise with aftermarket parts. By maintaining factory specifications, the condenser supports the overall health of the truck’s thermal management system.

In long-haul trucking, the condenser is vital for maintaining cabin temperature across diverse climates. Drivers spending hours on the highway require a consistent and powerful AC system. The DZ14251845057 ensures reliable performance from freezing mountains to scorching deserts.

Construction and mining trucks operate in dusty, high-temperature environments. The condenser’s design resists clogging from dust and provides efficient cooling despite poor airflow conditions. This is essential for operator comfort and equipment reliability on remote job sites.

Refrigerated transport (reefer trucks) often have separate cooling systems, but the cab AC remains critical. A dependable condenser ensures driver comfort without taxing the primary refrigeration unit. This supports overall logistics efficiency and cargo integrity.

Municipal and utility fleets, such as garbage trucks or fire engines, require reliable HVAC for crew safety and comfort during stop-and-go operations. The condenser’s durability against vibration and frequent thermal cycles makes it ideal for these demanding applications.

In regional distribution, where trucks make multiple stops daily, the AC system cycles frequently. The condenser’s efficient design handles these rapid load changes without performance degradation. This ensures driver comfort throughout the delivery route.

The Shacman Condenser DZ14251845057 represents the pinnacle of reliability and efficiency in vehicle thermal management. Its advanced engineering, rigorous manufacturing, and proven compatibility make it an indispensable component for maintaining optimal cabin climate and system performance.

Investing in this genuine OEM part safeguards driver comfort, reduces operational costs, and enhances vehicle uptime. By choosing DZ14251845057, fleet operators and owners ensure their Shacman trucks are equipped to handle the most demanding conditions with unwavering cooling performance.

For any replacement or service need, specifying the correct part number guarantees a perfect fit and restored functionality. Trust in the quality and durability of the Shacman Condenser to keep your cooling system running smoothly for miles ahead.