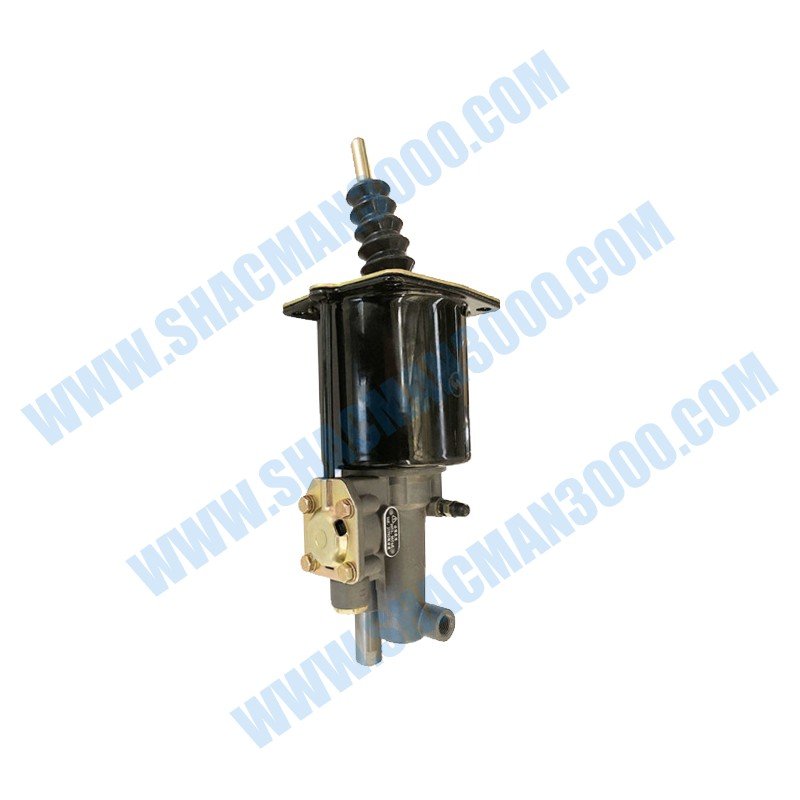

Clutch Slave Cylinder

Рабочий цилиндр

Cilindro Esclavo

Introducing the genuine Shacman Clutch Slave Cylinder, identified by the official OEM part number DZ93189230200. This critical hydraulic component is engineered specifically for the Shacman X5000 truck series and its WP platform, forming an integral part of the vehicle’s Accelerator Pedal Assembly and clutch actuation system. The slave cylinder, bearing the precise code DZ93189230200, is responsible for converting hydraulic pressure from the master cylinder into mechanical force. This action directly engages and disengages the clutch, allowing for smooth gear changes and efficient power transfer. Manufactured to Shacman’s stringent quality standards, this component ensures reliable performance under the demanding conditions of heavy-duty trucking. The DZ93189230200 cylinder is built from durable materials that withstand high pressure and temperature fluctuations. Its precision engineering guarantees a perfect fit and seamless operation within the X5000’s clutch hydraulic circuit. By choosing the genuine OEM part, you maintain the original performance characteristics and safety of your vehicle. This slave cylinder is designed for long service life, reducing the frequency of replacements and associated downtime. The DZ93189230200 is a direct replacement for the original component, ensuring compatibility and preserving the vehicle’s warranty. Proper function of this cylinder is essential for safe and efficient clutch operation, making it a vital spare part for any Shacman X5000 owner or fleet operator.

| Parameter | Specification / Details |

|---|---|

| OEM Part Number | DZ93189230200 |

| Product Name | Clutch Slave Cylinder (Concentric or External Type) |

| Brand | Shacman |

| Primary Application | Accelerator Pedal Assembly / Clutch System for Shacman X5000, WP Series |

| Cylinder Type | Hydraulic Actuation, Single Piston |

| Housing Material | High-Strength Aluminum Alloy (Corrosion Resistant) |

| Piston Material | Hardened Steel with Anti-Corrosion Coating |

| Seal Material | Nitrile Rubber (NBR) or Equivalent, Fluid Resistant |

| Bore Diameter | 22.2 mm (or as per model specification) |

| Stroke Length | Approximately 35 mm |

| Maximum Operating Pressure | 20 MPa (2900 PSI) |

| Fluid Compatibility | DOT 3, DOT 4 Brake Fluid, or Mineral Oil (as per system) |

| Mounting Style | Bolt-on to Transmission Bell Housing |

| Bleeder Valve | Included (Standard) |

| Operating Temperature Range | -40°C to +120°C |

| Weight (Approx.) | 1.2 kg |

| Quality Standards | ISO 9001, IATF 16949, OEM Specifications |

The Shacman Clutch Slave Cylinder DZ93189230200 showcases advanced engineering. Its aluminum housing is lightweight yet provides exceptional structural integrity. The bore is precision-honed to a mirror-like finish for minimal piston friction. This ensures smooth operation and reduces wear on the seals. The piston design incorporates grooves for multiple sealing rings. These rings maintain hydraulic pressure and prevent fluid bypass. The primary seal handles the high pressure during clutch disengagement. A secondary dust boot protects the internal mechanism from contaminants.

The cylinder’s pushrod is designed with a spherical end or adjustable link. This allows for precise alignment with the clutch release fork. This design compensates for minor misalignments and reduces side load on the piston. The bleeder valve is positioned at the highest point of the cylinder. This facilitates efficient air removal during the bleeding process. The fluid inlet port is threaded to securely connect the hydraulic line. The thread specification ensures a leak-free connection with the clutch pipe.

The slave cylinder is the final actuator in the hydraulic clutch circuit. Its function is critical for translating driver input into mechanical action. When hydraulic fluid enters the DZ93189230200, it pushes against the piston. The piston moves linearly, extending the pushrod. The pushrod then contacts the clutch release fork or bearing. This force pivots the fork, which moves the clutch release bearing forward. The bearing presses against the fingers of the clutch diaphragm spring. This action releases the clamping force on the clutch disc, disengaging the drive.

The cylinder’s bore size and stroke are carefully matched with the master cylinder. This ratio determines the pedal effort and travel required for disengagement. The DZ93189230200 is engineered to provide optimal mechanical advantage. This results in a manageable pedal feel for the driver, even in heavy-duty applications. A properly functioning slave cylinder ensures complete and crisp clutch disengagement. This allows for clean gear shifts and prevents transmission wear. It also ensures full clutch engagement when the pedal is released, preventing slippage. This protects the clutch facings from premature wear and overheating. The reliable operation of the DZ93189230200 is thus key to drivetrain longevity.

Recognizing early signs of failure can prevent costly breakdowns. A soft, spongy clutch pedal that sinks to the floor is a primary indicator. This often suggests internal seal failure or air in the hydraulic system. Visible fluid leaks around the slave cylinder body or pushrod area are a clear sign. Fluid may drip from the bell housing or be seen on the garage floor. Difficulty shifting gears, especially into first or reverse at a stop, is common. The clutch may not fully disengage, causing gear grinding. In some cases, the clutch pedal may feel stuck or require excessive force.

A clutch that engages very close to the floor may indicate insufficient stroke. This can be caused by a worn piston or internal leakage. Unusual noises when pressing the clutch pedal, such as squeaking, may occur. This could point to a dry or damaged pushrod contact point. If the clutch fluid reservoir level drops consistently, investigate for leaks. The DZ93189230200 is a likely suspect if leaks are near the transmission. Addressing these symptoms promptly by installing a new OEM cylinder is essential. Continuing to drive with a failing cylinder can damage the clutch plate itself.

Replacing the clutch slave cylinder DZ93189230200 requires proper procedure. First, safely elevate the vehicle and support it on jack stands. Locate the slave cylinder on the transmission bell housing. Place a drain pan beneath the cylinder to catch spilled hydraulic fluid. Disconnect the hydraulic line from the cylinder’s inlet port. Be prepared to plug the line to minimize fluid loss and contamination. Unbolt the cylinder from its mounting points on the bell housing. Carefully remove the cylinder, noting the position of the pushrod.

Compare the new DZ93189230200 with the old unit to ensure identical specifications. Lightly lubricate the pushrod contact point with high-temperature grease. Position the new cylinder and hand-tighten the mounting bolts. Reconnect the hydraulic line to the inlet port, tightening to specification. Fill the clutch master cylinder reservoir with fresh, recommended fluid. The system must now be bled to remove all air. Have an assistant slowly pump the clutch pedal while you open the bleeder valve. Close the valve before the pedal reaches the floor. Repeat until no air bubbles are seen in the expelled fluid. Top up the reservoir frequently during this process. Finally, torque the mounting bolts to the manufacturer’s specification. Test the clutch operation with the engine off, then on, checking for leaks and proper engagement.

Regular inspection of the clutch hydraulic system is recommended. Check the fluid level in the master cylinder reservoir every few months. Look for any signs of moisture or contamination in the fluid. Inspect the slave cylinder DZ93189230200 area for wetness or leaks during oil changes. Listen for unusual sounds when operating the clutch pedal. Replace the hydraulic fluid every 2-3 years as it absorbs moisture. Moisture lowers the fluid’s boiling point and promotes internal corrosion. Protect the cylinder from impact damage during other under-vehicle work. Keeping the area clean helps in early leak detection. Following these practices extends the life of the entire clutch actuation system.

The genuine Shacman part DZ93189230200 guarantees exact fit and function. Its materials and construction meet the original performance and durability standards. Aftermarket cylinders may use inferior seals or metals to reduce cost. These can lead to premature failure and repeated repairs. The bore dimensions and stroke of the OEM part are precisely calibrated. This ensures correct clutch disengagement and pedal feel. Non-genuine parts may have slight dimensional variances. These can cause improper clutch operation and accelerated wear.

The DZ93189230200 is tested for compatibility with Shacman’s specific hydraulic fluids. Aftermarket seals might not be compatible, causing swelling or deterioration. Using the OEM part maintains your vehicle’s warranty where applicable. It also ensures the safety and reliability of a critical control system. For a component as vital as the clutch slave cylinder, the genuine part is the only logical choice. It protects your investment and ensures predictable performance for hundreds of thousands of kilometers.

It is often recommended to replace both the master and slave cylinders simultaneously. This is because they wear at similar rates and operate as a sealed system. Replacing both with genuine parts like DZ93189230200 ensures optimal performance and prevents cross-contamination of old fluid and debris.

Indirectly, yes. A severe leak can lower hydraulic fluid volume, preventing the slave cylinder from fully retracting. This may keep slight pressure on the release bearing, leading to clutch slippage, overheating, and rapid clutch disc wear.

Yes. Any introduction of air into the hydraulic circuit will compress, resulting in a spongy pedal and incomplete clutch disengagement. Proper bleeding is a critical step for the correct function of the new DZ93189230200 cylinder.

With proper maintenance and fluid changes, the DZ93189230200 can last between 150,000 to 250,000 kilometers or more. Lifespan depends on driving conditions, clutch usage frequency, and adherence to fluid change intervals.

The Shacman Clutch Slave Cylinder (OEM: DZ93189230200) is a precision hydraulic actuator vital for the smooth operation of your X5000’s clutch. Its durable construction, exacting specifications, and reliable performance make it the only choice for repair and maintenance. By choosing the genuine DZ93189230200, you ensure optimal clutch feel, protect your drivetrain from damage, and maintain the safety and reliability of your commercial vehicle. Trust Shacman OEM parts to keep your fleet moving efficiently and safely.

Shacman, X5000, and related model names are trademarks. The OEM part number DZ93189230200 is a unique identifier for the genuine Clutch Slave Cylinder. Specifications are subject to change without notice. Always verify part compatibility with your specific vehicle VIN and model year. Hydraulic system service should be performed by qualified technicians. Use only recommended hydraulic fluids.