Key Issue Overview:

Experiencing a lack of power or sluggish acceleration in your SHACMAN truck is a common but complex issue. It often signals problems within the engine’s vital systems: Air Intake, Fuel Delivery, Exhaust/Aftertreatment, or Electronic Controls. A systematic approach to diagnosing the SHACMAN Truck Underpowered condition is crucial for a cost-effective and lasting repair. Ignoring it can lead to increased fuel consumption, higher emissions, and severe engine damage.

This comprehensive guide details the most common culprits—from simple clogged filters to intricate sensor faults—and provides clear, step-by-step solutions to restore your truck’s full performance and hauling capability.

SHACMAN Truck Underpowered

When your SHACMAN truck feels weak, it’s usually because one of its core systems isn’t functioning optimally. The engine might be starved for air, not getting enough fuel, struggling to exhale, or receiving incorrect computer commands. Below is a detailed breakdown of each system, common failing parts, and actionable solutions to address the SHACMAN Truck Underpowered problem efficiently.

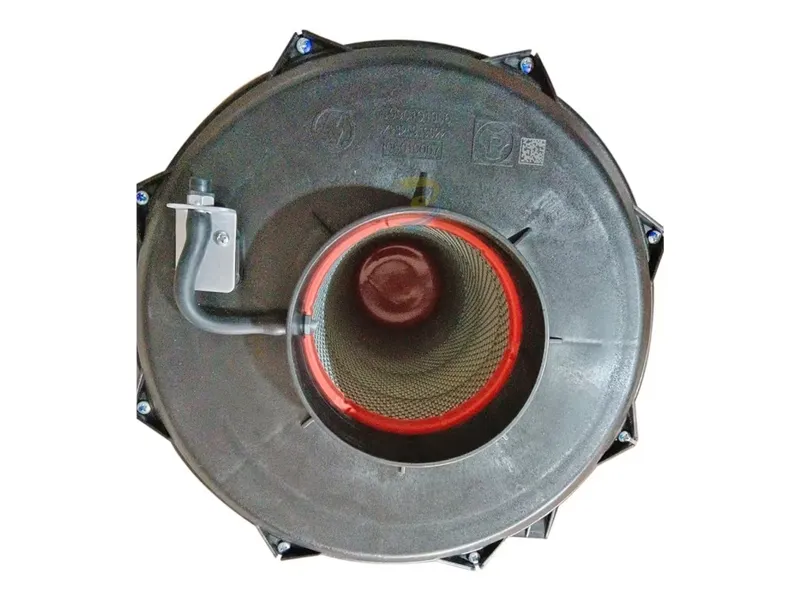

The engine needs a massive, clean air supply for combustion. Any restriction here directly causes a SHACMAN Truck Underpowered condition.

A dirty air filter is the most common and easily fixable cause. It chokes the engine, creating a rich fuel mixture and poor combustion.

Solution: Inspect the filter element. Replace it if dirty. For severe environments, check more frequently.

The turbo is critical for power. Worn bearings, damaged blades, or a stuck wastegate actuator reduce boost pressure significantly.

Solution: Listen for unusual whining or grinding noises. Check for shaft play and inspect the intercooler pipes for oil leaks indicating seal failure.

Cracks or loose clamps on intake hoses or intercooler cause unmetered air entry and loss of pressurized boost.

Solution: Visually inspect all pipes from the turbo to the intake manifold. Tighten clamps and replace any cracked or swollen hoses.

Contaminated fuel, poor filtration, or failing injection components are prime suspects for a SHACMAN Truck Underpowered scenario, especially under load.

Clogged primary and secondary fuel filters restrict flow to the high-pressure pump, starving the engine.

Solution: Adhere strictly to replacement intervals. Use only high-quality, OEM-specified filter cartridges.

Worn or clogged injectors cause poor fuel atomization, misfires, and unbalanced cylinder power.

Solution: Perform a cylinder cut-out test. Diagnose with an electronic scanner. Clean or replace faulty injectors in sets if needed.

A weak transfer pump or failing high-pressure pump cannot maintain the rail pressure required for full power.

Solution: Use a diagnostic tool to monitor actual vs. desired rail pressure. Check the fuel pressure relief valve and pump control unit.

For modern SHACMAN trucks (Euro IV/V/VI), a restricted exhaust is a leading cause of the SHACMAN Truck Underpowered fault, often triggering enforced “limp mode.”

A saturated DPF creates extreme backpressure, forcing the ECU to drastically reduce engine output to prevent damage.

Solution: Initiate a forced parked regeneration via the dashboard button or diagnostic tool. If blocked severely, professional cleaning or replacement is necessary.

Faulty urea dosing, a clogged injector, or NOx sensor errors can cause the ECU to limit torque to comply with emissions laws.

Solution: Check AdBlue quality and tank level. Inspect the urea pump and injector for crystallization. Read and clear fault codes.

A butterfly valve that fails to open fully acts as a constant restriction in the exhaust pipe.

Solution: Manually check the exhaust brake valve for free movement. Inspect the pneumatic or electric actuator.

Incorrect data from sensors forces the Engine Control Unit (ECU) to make poor decisions, leading to a SHACMAN Truck Underpowered state without obvious mechanical faults.

Faulty Mass Airflow (MAF), Boost Pressure, Fuel Rail Pressure, or Throttle Pedal Position sensors send wrong signals to the ECU.

Solution: Connect a heavy-duty diagnostic scanner. Compare live data from sensors against standard values. Check wiring harnesses for damage.

The ECU will proactively limit power to protect the engine or emissions system when it detects a severe fault.

Solution: A full system scan is mandatory to identify the triggering fault code (e.g., aftertreatment faults, overheating, overboost).

Sometimes, the root of a SHACMAN Truck Underpowered complaint lies in the engine’s internal mechanics or the truck’s drivetrain.

Worn piston rings, cylinder liners, or leaking valves reduce combustion efficiency.

Solution: Perform a compression test. Significant variation between cylinders indicates internal wear requiring major overhaul.

Stretched timing gears or a jumped timing belt/chain disrupt the precise valve and injection timing.

Solution: Verify timing marks alignment. This is a complex procedure best left to qualified technicians.

Dragging brakes, underinflated tires, or a seized bearing create extra load, making the engine work harder.

Solution: Check for hot wheel hubs after a run. Ensure tire pressures are correct and the parking brake fully releases.

To effectively solve a SHACMAN Truck Underpowered issue, follow a logical sequence. This prevents wasted time and money on unnecessary parts.

For persistent or complex cases of a SHACMAN Truck Underpowered truck, seeking help from an authorized SHACMAN service center with specialized tools and training is highly recommended. Learn more about professional maintenance schedules and technical support to keep your fleet running at peak performance.

For natural gas-powered SHACMAN trucks experiencing a SHACMAN Truck Underpowered condition, the diagnostic path differs.

Worn spark plugs, faulty ignition coils, or bad high-voltage wires cause misfires and power loss.

Solution: Inspect and replace spark plugs at recommended intervals. Check coil output with an oscilloscope.

Low gas pressure from a failing regulator, solenoid valve, or frozen LNG vaporizer results in lean combustion and weak performance.

Solution: Monitor high and low-pressure gas sensors. Check the pressure relief valves and heating system for the vaporizer.

Final Recommendation: A SHACMAN Truck Underpowered problem is a symptom, not a cause. Successful repair depends on accurate diagnosis. Start with simple, low-cost items like filters before moving to complex components. Regular, preventative maintenance is the most effective strategy to avoid unexpected downtime and power loss in your SHACMAN truck fleet.